AMA vs NMN vs DMD: Choosing the Right Electrical Insulation Material for Motors

When it comes to electrical motor manufacturing and repair, choosing the right insulation material is critical for ensuring reliability, safety, and extended service life. Among the most widely used insulation materials are AMA, NMN, and DMD. Each material has unique compositions, properties, and application advantages. In this article, we’ll compare them in detail to help you make the right choice for your motor insulation needs.

1. AMA Insulation Material

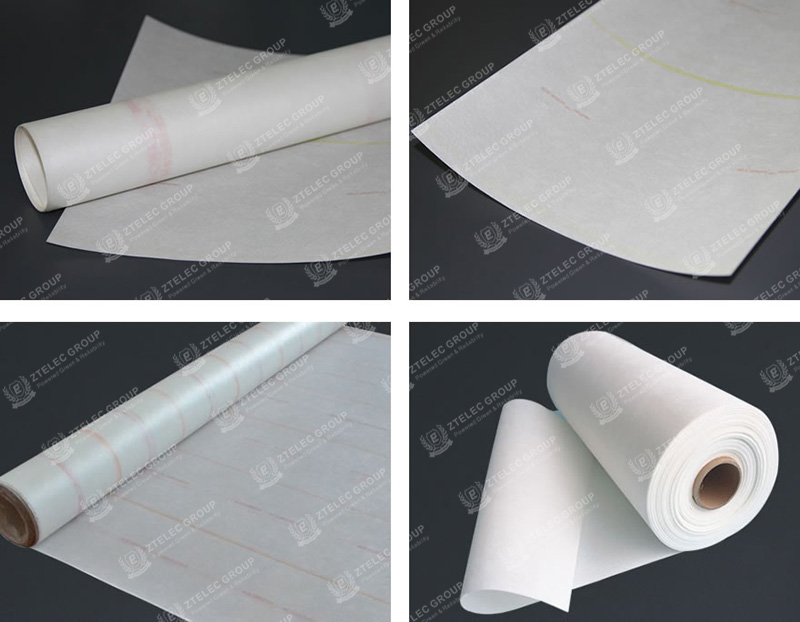

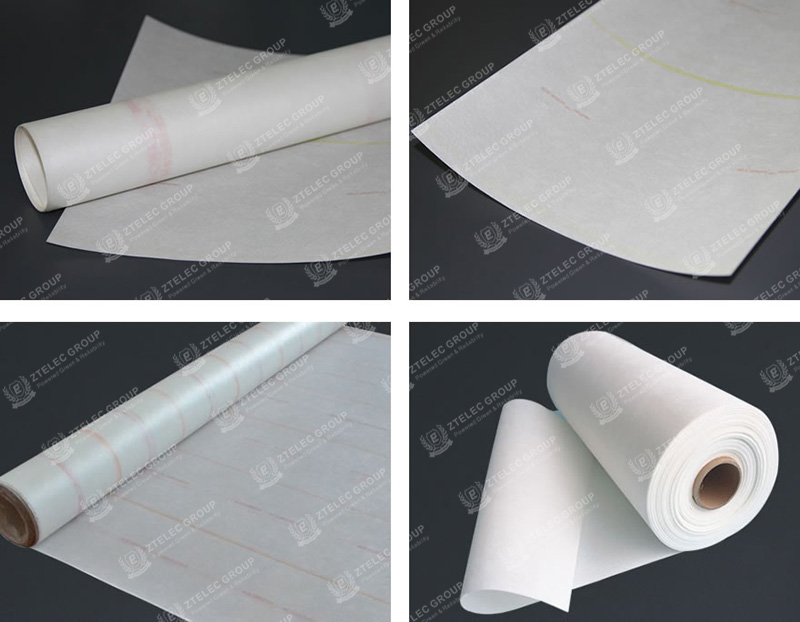

What is AMA?

AMA stands for Aramid–Polyester–Aramid composite paper. It is a three-layer flexible insulation material with aramid paper on both sides and polyester film in the middle.

Key Features:

• Excellent thermal resistance (Class F, 155°C)

• Good dielectric strength and mechanical toughness

• Resistant to aging and moisture

• Stable electrical performance even under long-term heat exposure

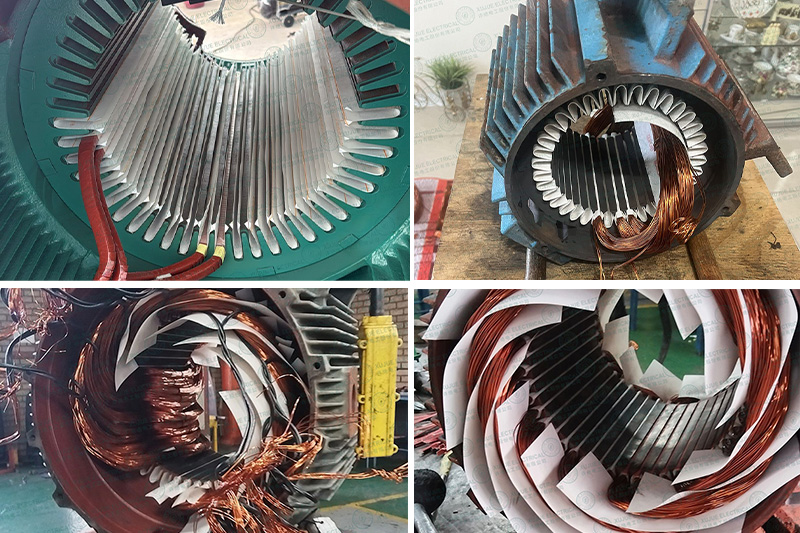

Applications in Motors:

• Slot insulation

• Phase insulation

• Interlayer insulation in small to medium-sized motors

• Electrical equipment requiring long-term reliability

2. NMN Insulation Material

What is NMN?

NMN refers to Nomex–Polyester–Nomex composite paper. It is made of Dupont Nomex aramid paper on both outer layers, with a polyester film core.

Key Features:

• High thermal class (Class F)

• Excellent mechanical strength combined with flexibility

• Outstanding dielectric properties

• Superior tear resistance compared to AMA

• Long service life in demanding environments

Applications in Motors:

• High-voltage motor insulation

• Slot liners and wedges

• Transformer layer insulation

• Applications requiring higher endurance against thermal stress

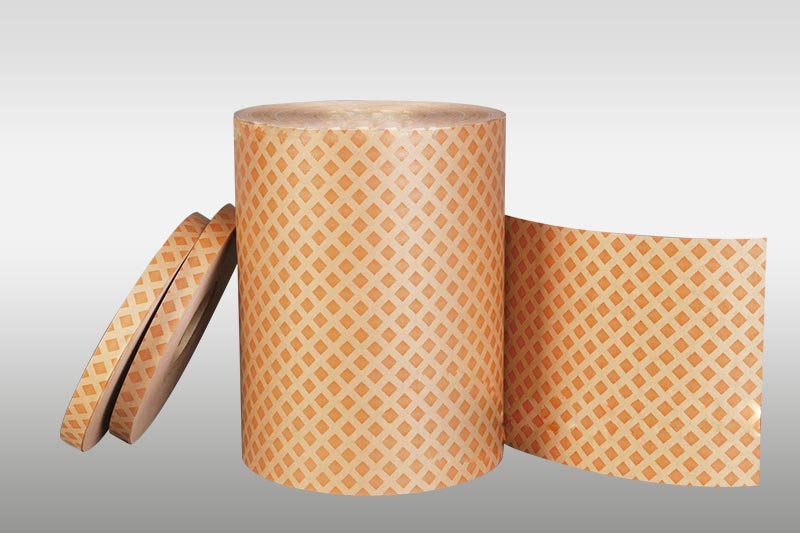

3. DMD Insulation Material

What is DMD?

DMD stands for Polyester Non-woven–Polyester Film–Polyester Non-woven composite material. It is a cost-effective insulation material commonly used in motor windings.

Key Features:

• Thermal Class: B (130℃) or F (155℃)

• Good mechanical properties

• Adequate dielectric strength for low- to medium-voltage applications

• Economical compared with NMN and AMA

• Can be resin-coated for enhanced heat resistance and adhesion

Applications in Motors:

• Slot insulation and interturn insulation in low- and medium-voltage motors

• Transformers, reactors, and household appliance motors

• Situations where cost-effectiveness is a priority

4. Comparative Table: AMA vs NMN vs DMD

|

Property / Material |

AMA (Aramid-Polyester-Aramid) |

NMN (Nomex-Polyester-Nomex) |

DMD (Polyester Non-woven-Polyester Film-Polyester Non-woven) |

|

Thermal Class |

F (155°C) |

F (155°C) |

B/F (130–155°C) |

|

Mechanical Strength |

Good |

Excellent |

Moderate |

|

Dielectric Strength |

High |

Very High |

Moderate to High |

|

Moisture Resistance |

Good |

Excellent |

Fair |

|

Cost Level |

Medium |

High |

Low |

|

Applications |

Motors, transformers, slot insulation |

High-voltage motors, transformers, heavy-duty insulation |

General motors, appliances, cost-sensitive projects |

5. How to Choose the Right Material?

• Choose AMA if you need balanced performance at moderate cost for general motor insulation.

• Choose NMN if your motor operates in high temperature and demanding environments where durability and reliability are critical.

• Choose DMD if you want a cost-effective solution for standard low- or medium-voltage motors.

Conclusion

The right insulation material depends on your motor’s operating environment, thermal requirements, and cost considerations. AMA, NMN, and DMD each have their strengths, and selecting the right one ensures your motor delivers safe, efficient, and long-lasting performance.

At ZTelec, we provide high-quality AMA, NMN, and DMD insulation materials tailored for different motor and transformer applications. Contact us for technical support and customized solutions.