How to Identify a Truly High-Quality Epoxy Sheet: A Professional Buyer’s Guide

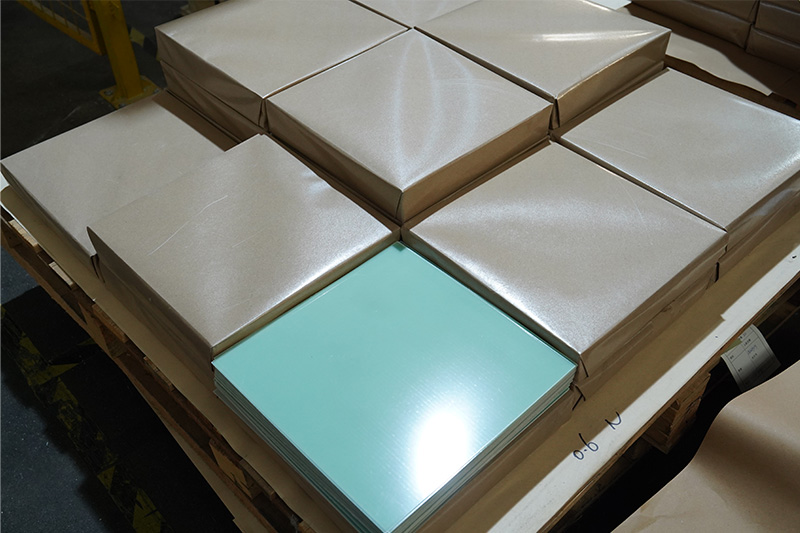

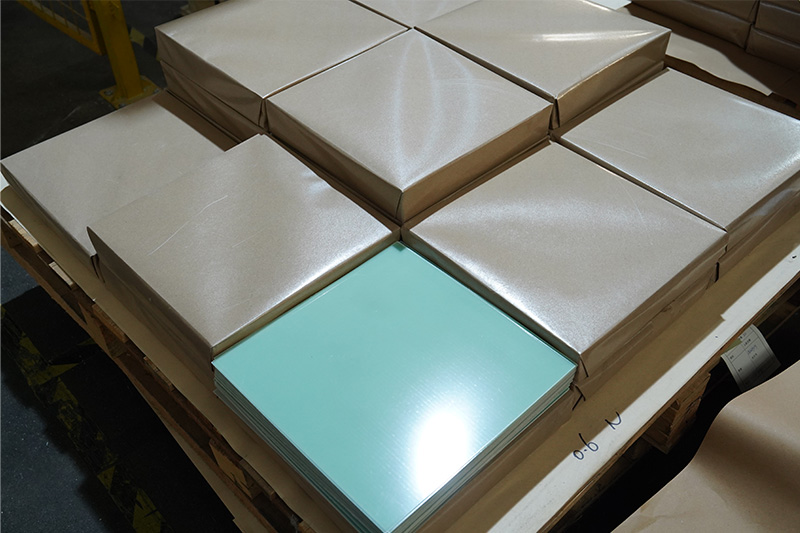

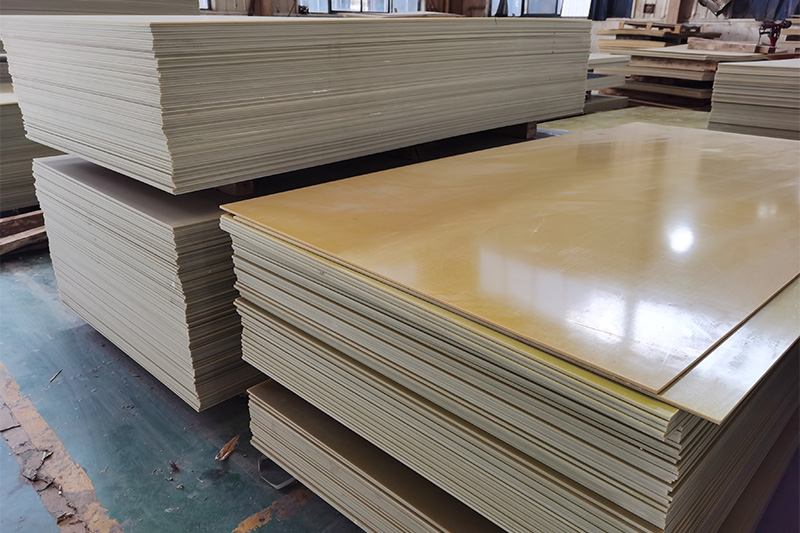

Epoxy laminated sheets—also known as epoxy fiberglass sheets or FR4/G10 boards—are essential materials in electrical insulation, mechanical support, and electronic applications. However, not all epoxy sheets perform equally well under heat, load, or moisture. To ensure long-term safety and performance, it’s crucial to understand the underlying material science behind a high-quality epoxy sheet.

This comprehensive guide helps industrial buyers, engineers, and procurement managers identify the real difference between ordinary and premium-grade epoxy insulation materials.

1. Core Principle: Cross-Link Density and Molecular Network Stability

The strength and reliability of an epoxy laminated sheet come from its cross-linked molecular network formed during curing. This cross-linking density determines the glass transition temperature (Tg), dimensional stability, and resistance to creep or relaxation over time.

High cross-link density = better mechanical rigidity, thermal endurance, and moisture resistance.

Low-quality epoxy sheets may appear strong initially but will soften, deform, or delaminate when exposed to long-term heat and electrical load.

Pro Tip: Ask your supplier whether the epoxy resin system uses high-purity E-glass cloth and a fully cured bisphenol-A or bisphenol-F epoxy system. These ensure a stable 3D molecular network.

2. Creep Resistance and Long-Term Aging Behavior

Mechanical test values (like tensile or flexural strength) reflect only short-term behavior. For transformers, motors, and switchgear, creep resistance—the material’s ability to maintain shape under constant stress—is far more critical.

High-quality epoxy fiberglass sheets maintain their flexural strength even after 1,000–10,000 hours under load at elevated temperatures. Poorly cured sheets, on the other hand, show permanent deformation or delamination.

Ask for:

• Creep test curves over time (at 23 °C and 150 °C)

• Aging test data after 1000h or 5000h

• Dielectric strength retention after aging

3. Environmental Stability: Heat, Moisture, and Thermal Cycling

Industrial insulation materials often face harsh environmental conditions. Here’s what defines a reliable epoxy insulation sheet:

3.1 Glass Transition Temperature (Tg)

The Tg should always be at least 20–30 °C higher than the operating temperature.

For most FR4 epoxy sheets, Tg ≈ 130–140 °C, while G11 high-temperature epoxy boards can reach 155–180 °C.

A DMA (Dynamic Mechanical Analysis) curve is a more accurate way to evaluate modulus retention near Tg.

3.2 Moisture Absorption and Hydrothermal Aging

Moisture infiltration can lower dielectric strength and cause microcracking.

Check the 24 h/72 h water absorption rate—top-grade FR4 epoxy fiberglass boards keep it under 0.15%.

Also, ask for dielectric performance after damp-heat cycling.

3.3 Thermal Expansion and Layer Adhesion

If the coefficient of thermal expansion (CTE) is mismatched between fiberglass and resin, the laminate may delaminate after repeated thermal shocks.

High-quality epoxy laminated boards undergo 100-cycle thermal shock tests to ensure structural integrity.

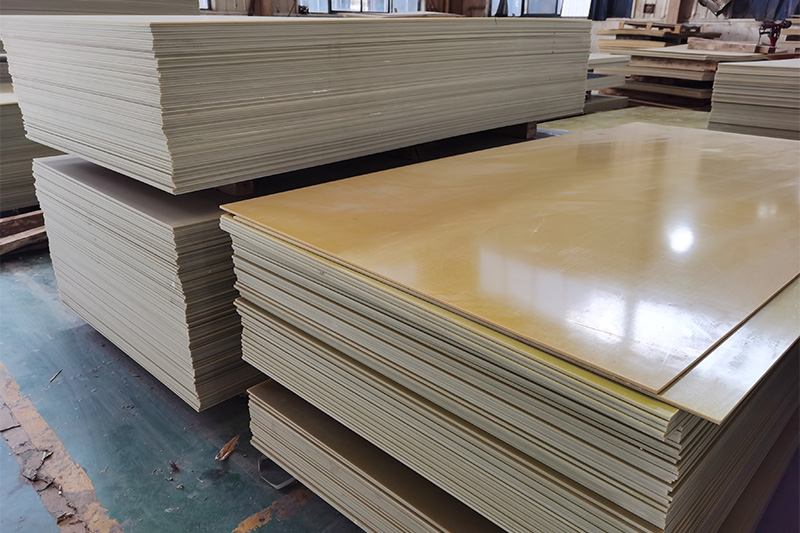

4. Internal Structure: Resin-Fiber Interface and Lamination Quality

Under the microscope, you can literally see quality. A high-grade epoxy sheet has:

• Uniform resin distribution

• No voids, bubbles, or dry fiber areas

• Strong resin–fiber adhesion

Poor lamination or trapped air can lead to premature breakdown or layer separation. Reputable epoxy fiberglass sheet manufacturers use vacuum hot-press lamination and post-curing to ensure tight bonding between layers.

5. Material Grades Explained: G10, FR4, and G11

Not all “epoxy sheets” are equal—each grade serves a different application need.

|

Type |

Features |

Limitations |

Applications |

|

G10 Epoxy Sheet |

High mechanical strength, low cost |

Non-flame retardant |

Structural supports, mechanical fixtures |

|

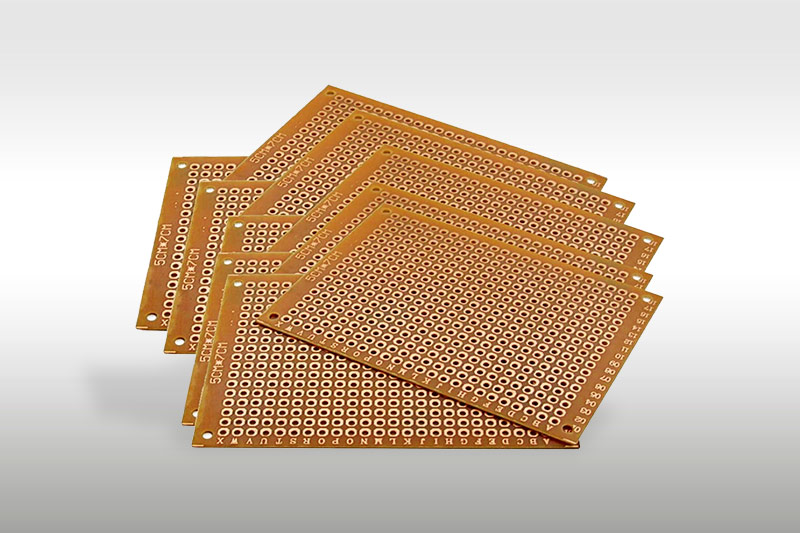

FR4 Epoxy Board |

Flame-retardant (UL94 V-0), good balance of strength and insulation |

Slightly lower cross-link density |

PCB base, transformer components |

|

G11 Epoxy Sheet |

High Tg (up to 180 °C), excellent heat stability |

More expensive |

Motors, generators, dry-type transformers |

6. Key Performance Metrics to Verify Before Purchase

To ensure that your epoxy insulation material will perform reliably, check these technical indicators:

• Dielectric Strength: ≥14 kV/mm

• Insulation Resistance: ≥1 × 10¹² Ω

• Flexural Strength: ≥340 MPa

• Compressive Strength: ≥400 MPa

• Water Absorption: ≤0.15%

• Thermal Class: B (130 °C) or F (155 °C)

Confirm that all values are tested under IEC 60893 or NEMA G10/FR4/G11 standards.

7. Supplier Evaluation and Testing Verification

When sourcing epoxy fiberglass boards, partner only with certified manufacturers who can provide:

• ISO9001 / RoHS / UL certificates

• DMA, Creep, and Thermal Shock test data

• CNC machining tolerance reports

• Sample inspection and batch test records

Practical Tip:

Include performance retention clauses in your purchase agreement—especially for high-load or high-temperature environments—to guarantee quality consistency.

8. Application-Based Quality Priorities

|

Application |

Recommended Epoxy Sheet |

Key Focus |

|

Transformer insulation |

FR4 / G11 epoxy sheet |

Dielectric strength, oil resistance |

|

Motor slot insulation |

G11 high-temperature epoxy board |

Thermal stability, creep resistance |

|

PCB manufacturing |

FR4 epoxy laminated board |

Flame retardancy, dimensional precision |

|

Battery pack insulation |

FR4 sheet |

Arc resistance, machining tolerance |

9. Conclusion

A high-quality epoxy laminated sheet is defined not only by its mechanical strength or color, but by its cross-link structure, long-term thermal stability, and resistance to moisture, creep, and delamination.

By focusing on molecular integrity, mechanical durability, and verified performance under real-world stress, you can ensure safe, long-lasting operation of your electrical or industrial systems.

If you’re looking for a reliable epoxy fiberglass sheet manufacturer, XuJue provides G10, FR4, and G11 epoxy laminates with certified quality, precision CNC machining, and global delivery support.