Electrical Paper Pressboard for Oil Transformers: Properties, Applications & Selection Guide

Electrical paper pressboard is one of the core solid insulation materials used in oil-immersed power transformers. Known for its excellent dielectric strength, mechanical rigidity, and oil compatibility, pressboard ensures the long-term stability and reliability of transformer operation. As global demand for higher-efficiency and longer-lifespan transformers grows, high-quality electrical pressboard has become essential in transformer manufacturing and refurbishment.

1. What Is Electrical Paper Pressboard?

Electrical pressboard is a cellulose-based insulation material made from 100% sulphate wood pulp or cotton-linter pulp. Through a mechanical pressing and drying process, the fibers form a dense and uniform structure. Its insulation performance is further optimized by high-temperature curing, making it suitable for harsh electrical and thermal environments inside power transformers.

Pressboard is typically used in combination with transformer insulating oil, forming a complete solid–liquid insulation system.

2. Key Features & Technical Advantages

High Dielectric Strength

Good cellulose purity and dense fiber structure give pressboard a dielectric strength of ≥70 kV/mm in oil, ensuring strong resistance to electrical stress.

Excellent Mechanical Strength

Pressboard maintains dimensional stability under high compression. Even in oil-filled conditions, it:

• Resists deformation

• Endures mechanical shock

• Withstands tightening forces in winding structures

Strong Oil Compatibility

During long-term immersion, the pressboard absorbs transformer oil, improving insulation and extending service life. No chemical reactions or degradation occur with qualified mineral oil or synthetic oils.

Thermal Class A (105°C)

Electrical pressboard can operate continuously at 105°C, and withstand short-term thermal stress during overload or short circuits.

Low Moisture & Dehydration Stability

Moisture significantly affects insulation performance. High-quality pressboard has:

• Initial moisture content below 10%

• Ability to reach <1% moisture after vacuum drying

This gives transformers higher dielectric reliability.

3. Main Applications in Oil-Immersed Transformers

Electrical pressboard is used throughout the insulation structure of power and distribution transformers, including:

Spacer blocks

Keep proper distance between low- and high-voltage winding layers.

End rings and cylinders

Provide mechanical support and insulation to winding ends.

Clamping and supporting parts

Enhance structural stability under short-circuit forces.

Oil duct spacing

Ensure smooth oil circulation and better heat dissipation.

Lead insulation and barrier boards

Prevent electrical breakdown between conductors.

Laminated structures

Made into 3-ply or multi-ply pressboard components for high-voltage insulation.

Its versatility makes it key to transformer performance, especially in medium and high voltage levels.

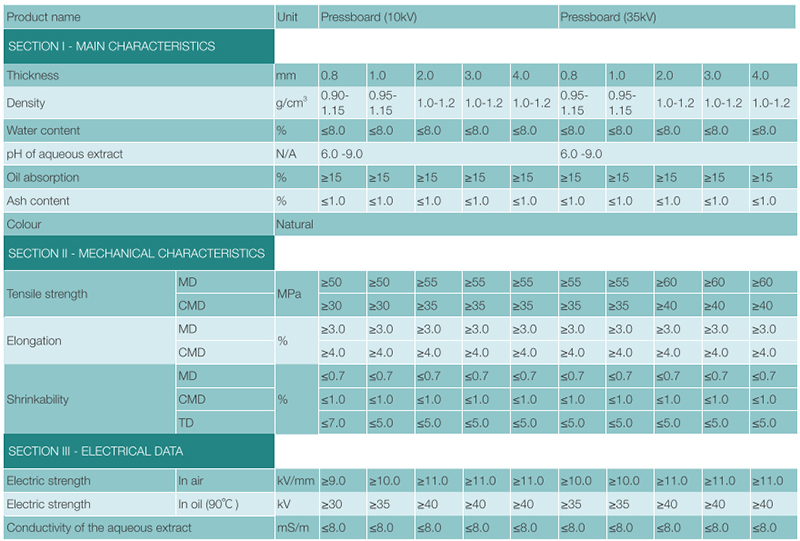

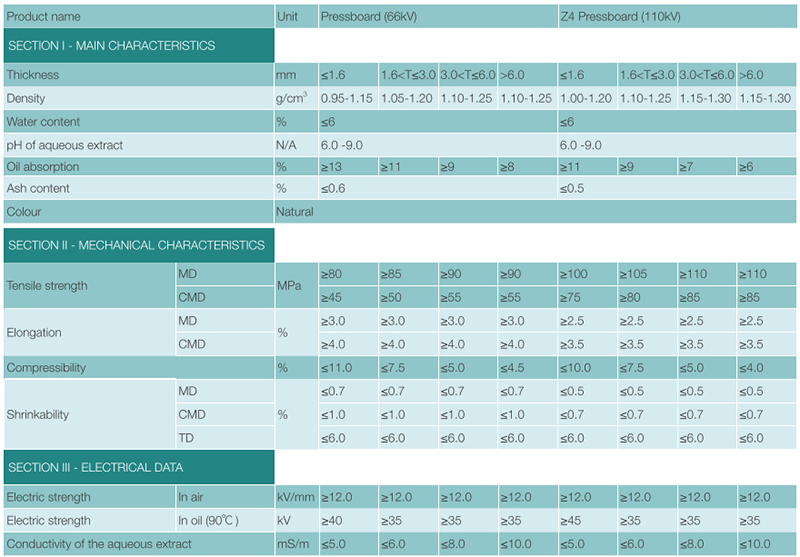

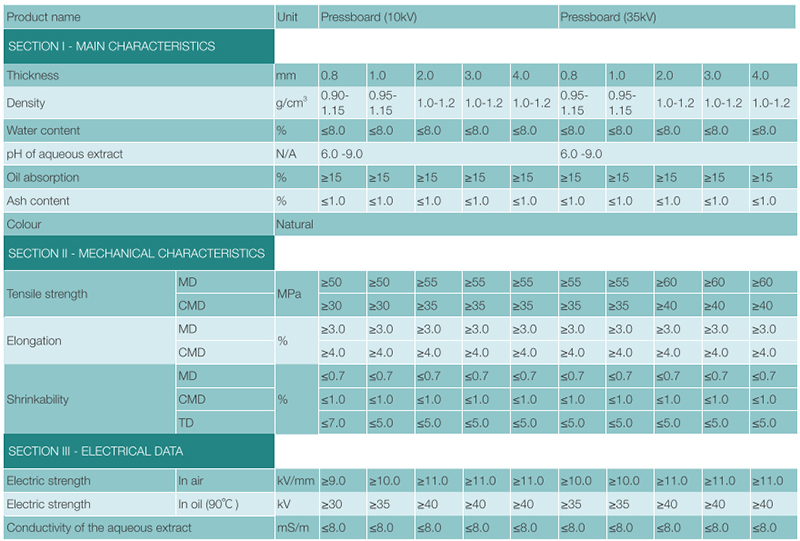

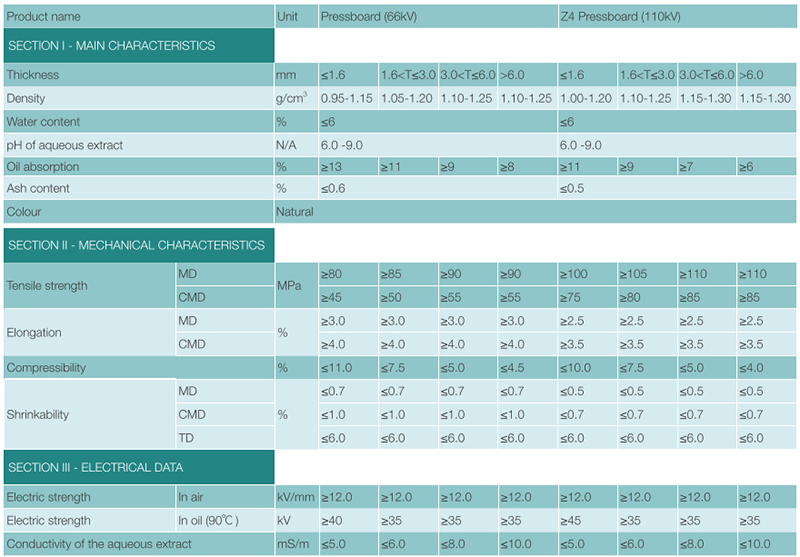

4. Performance Data (Typical Values)

5. Why Transformer Manufacturers Choose High-Quality Pressboard

A stable insulation system directly affects the life expectancy of a transformer. Using certified pressboard ensures:

• Reduced dielectric failures

• Lower partial discharge risk

• Better heat distribution

• Long-term mechanical stability

• Reliable service life up to 30+ years

For OEM transformer factories and maintenance companies, choosing high-grade cellulose pressboard significantly reduces failure rates and after-sales problems.

6. How to Select the Right Electrical Pressboard

When selecting pressboard for oil transformers, consider the following:

Thickness:

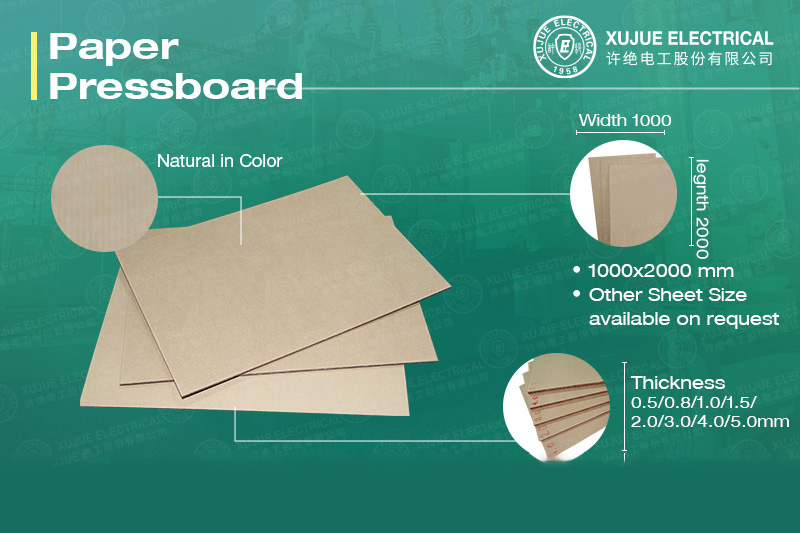

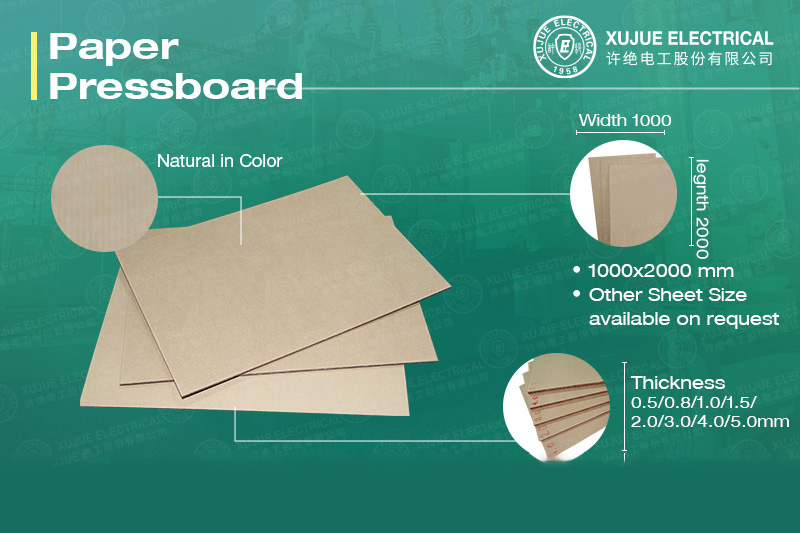

Common sizes range from 0.5 mm to 30 mm based on application.

Density and rigidity:

Higher density improves compression resistance and mechanical strength.

Certification:

Ensure compliance with IEC 60641

Moisture content:

Lower moisture means higher dielectric performance.

Processing capability:

Pressboard should be suitable for CNC machining, punching, and bending.

7. XuJue Electrical Pressboard – Reliable for Global Transformer Projects

As a manufacturer specializing in transformer insulation materials, XuJue supplies:

• High-density electrical pressboard

• 100% high purity sulphate wood pulp

• Precision-machined pressboard components

• Custom transformer insulation kits

We offer fast delivery, stable quality, and technical support for OEM transformer factories worldwide.