Epoxy Sheet vs. Bakelite: Which Is More Suitable for Electronics?

In the electronics industry, material selection directly impacts the reliability, safety, and performance of devices. Among various insulating materials, Epoxy Sheets and Bakelite Boards are two of the most widely used. Both offer good insulation and mechanical strength, but their characteristics differ significantly in thermal resistance, electrical stability, processing adaptability, and application environments. Understanding these differences is essential when choosing the right electrical insulation materials for PCB and electronic components.

1. Material Composition and Electrical Properties

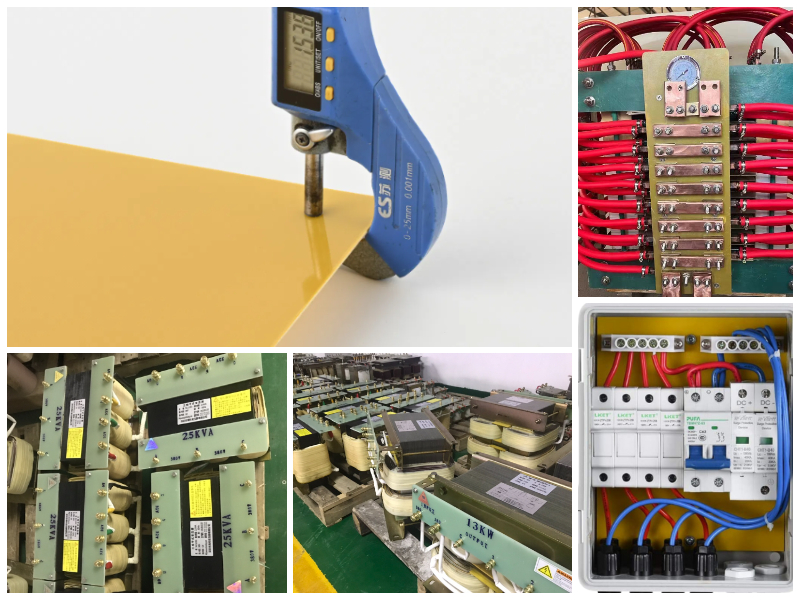

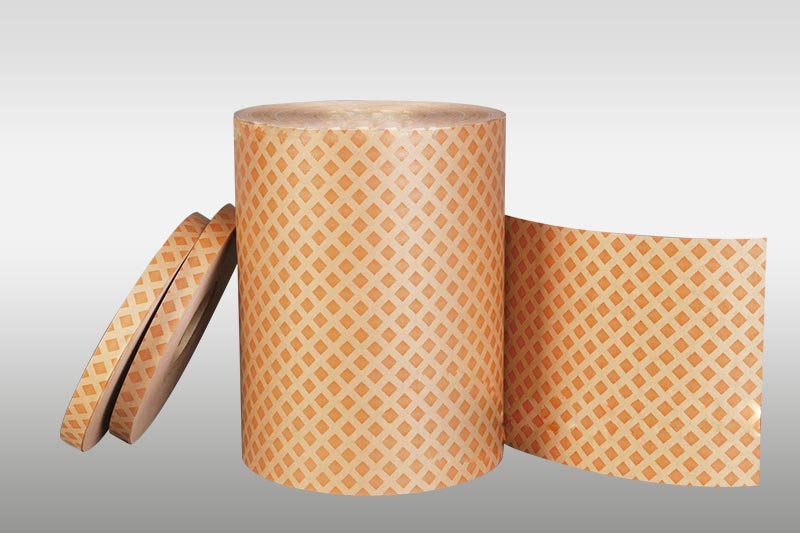

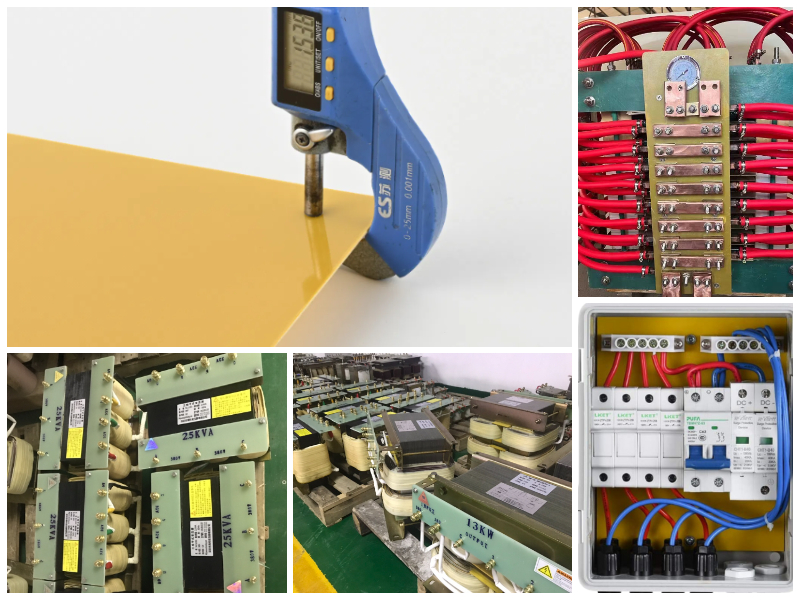

Epoxy Sheets (such as G10, FR4, and 3240) are composed of epoxy resin reinforced with fiberglass cloth. This combination provides excellent dielectric strength, high mechanical rigidity, and superior moisture resistance. They are ideal for printed circuit boards (PCBs), transformers, and electronic enclosures, where consistent electrical insulation is critical.

By contrast, Bakelite, also known as phenolic resin board, is made from phenolic resin and paper or cotton cloth base. It provides good insulation and machinability but has lower resistance to high temperatures and moisture compared with epoxy-based laminates. For applications that require high-voltage insulation or exposure to fluctuating environments, Bakelite may degrade faster.

Long-tail keywords embedded: epoxy sheet for electronics, bakelite board for circuit boards, electrical insulation materials for PCB.

2. Mechanical and Thermal Performance in Real Applications

Let’s consider two common cases in the electronics field:

Case 1: Power Supply Units (PSUs)

In high-power PSUs, components like transformers and capacitors operate under constant thermal stress. Epoxy laminated sheets maintain insulation integrity even at 155–180°C and under vibration, ensuring long-term performance stability.

Bakelite, however, may deform or lose dielectric strength above 120°C, making it less suitable for high-temperature environments.

Case 2: Control Panels and Relay Bases

For general electrical control systems that operate at moderate temperatures, Bakelite sheets are cost-effective and easy to machine into insulating barriers or structural bases. Their affordability and good rigidity make them a practical choice for low-voltage applications or household appliances.

Long-tail keywords embedded: high temperature insulation sheets, electrical insulation board for power supply, phenolic board for switchgear.

3. Environmental Resistance and Processing Considerations

Epoxy fiberglass sheets exhibit better dimensional stability and chemical resistance, maintaining insulation strength in humid or oily conditions. This makes them ideal for marine electronics, industrial inverters, and outdoor devices. Their glass fiber reinforcement also supports complex CNC machining for precision parts.

Bakelite, while easier to cut and drill, tends to absorb moisture over time and may crack under heavy mechanical load. Therefore, it’s typically preferred for dry indoor environments or temporary fixtures, rather than long-term electronic assemblies.

4. Choosing the Right Material for Your Project

When selecting between Epoxy Sheet vs. Bakelite, engineers should evaluate key factors including:

• Operating temperature range

• Moisture and chemical exposure

• Mechanical load and vibration

• Cost vs. reliability balance

If your project demands high dielectric strength and thermal endurance, epoxy sheets are the optimal choice. But if the design prioritizes cost-efficiency and easy processing for general applications, Bakelite remains a solid alternative.

Conclusion

In summary, both materials serve important roles in electronic insulation. However, for advanced electronic manufacturing, PCB fabrication, and high-performance transformers, Epoxy Sheets for electronics outperform Bakelite in terms of thermal stability, moisture resistance, and long-term reliability. Bakelite, meanwhile, retains value in cost-sensitive, moderate-performance electrical systems.

Whether designing industrial control systems or precision circuit boards, choosing the right insulation material can mean the difference between consistent reliability and premature failure.