Epoxy Laminated Sheets for Transformer Insulation: Applications and Selection Guide

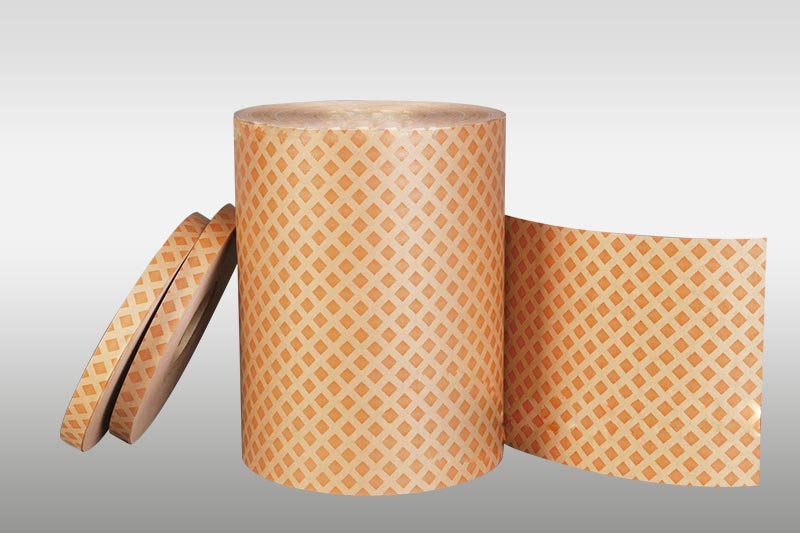

When it comes to transformer insulation, epoxy laminated sheets are among the most reliable and widely used insulating materials. These sheets, also known as epoxy glass cloth laminated sheets, combine excellent electrical insulation, mechanical strength, and thermal resistance, making them a preferred choice in modern transformer design.

In this article, we will explore the applications of epoxy laminated sheets in transformers and provide a selection guide to help engineers, manufacturers, and buyers choose the right material for their specific requirements.

What Are Epoxy Laminated Sheets?

Epoxy laminated sheets are composite insulation materials made by impregnating fiberglass cloth or other substrates with epoxy resin under high temperature and pressure.

Types of Epoxy Laminated Sheets (3240, FR4, G10, G11)

• 3240 epoxy sheet (widely used for transformer insulation and electrical equipment)

• FR4 insulation sheet (high mechanical strength and flame resistance, suitable for precision electrical devices)

• G10 and G11 epoxy sheets (excellent dielectric strength and good mechanical properties at high temperatures)

Key Properties of Epoxy Glass Cloth Laminated Sheet

These sheets are known for their excellent dielectric properties, moisture resistance, arc resistance, and machinability, making them suitable for both electrical insulation and structural applications.

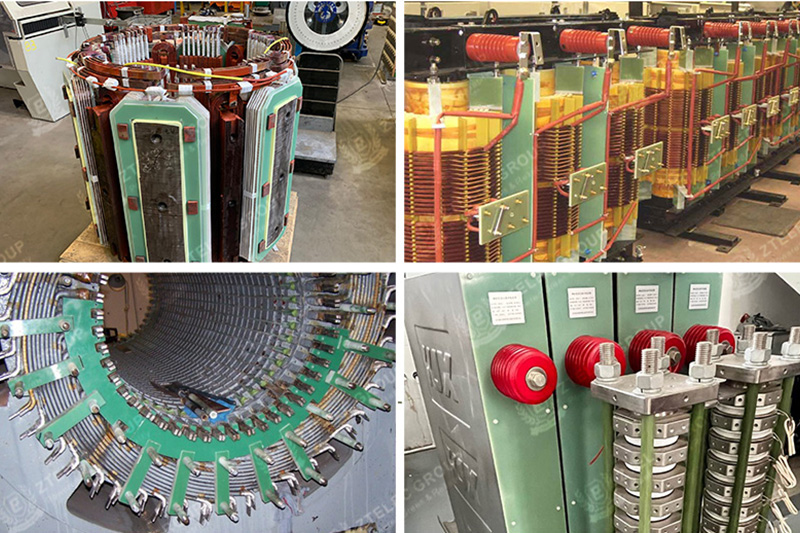

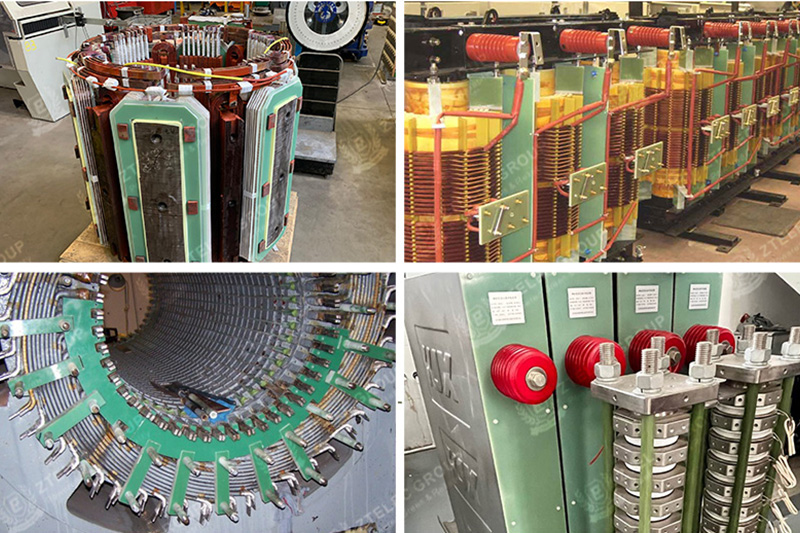

Applications of Epoxy Laminated Sheets in Transformers

1. Winding Insulation Support

Epoxy sheets are used as structural supports and barriers between transformer windings, preventing short circuits and ensuring long-term stability.

2. Core and Coil Insulation

High dielectric strength ensures safe insulation between the transformer core and coils, reducing the risk of electrical breakdown.

3. Spacer Blocks and Clamping Parts

Custom epoxy laminated insulation parts are often machined into spacers, clamping plates, and support blocks for mechanical reinforcement.

4. Terminal Boards and Insulating Barriers

Their heat resistance and mechanical stability make epoxy laminated sheets suitable for terminal boards, arc barriers, and contact supports in both dry-type and oil-immersed transformers.

How to Select the Right Epoxy Laminated Sheet for Transformer Insulation

When choosing an epoxy laminated sheet, engineers should consider the following factors:

1. Electrical Performance

For high-voltage transformers, 3240 epoxy sheet or FR4 insulation sheet provides superior dielectric strength.

For low- and medium-voltage transformers, standard epoxy resin laminated sheets can be sufficient.

2. Thermal Class

G11 epoxy sheets are recommended for environments where higher thermal resistance is required.

FR4 sheets are ideal for flame-retardant applications.

3. Mechanical Properties

For heavy-duty clamping and load-bearing parts, epoxy glass cloth laminated sheet for transformer insulation offers high compressive strength.

4. Customization Needs

Many epoxy resin laminated sheet suppliers provide CNC machining services to produce custom epoxy laminated insulation parts, tailored to transformer designs.

Advantages of Using Epoxy Laminated Sheets in Transformers

• High electrical insulation → ensures safe operation of transformers.

• Excellent mechanical strength → withstands mechanical stress during operation.

• Moisture and arc resistance → reliable in humid or high-voltage environments.

• Machinability → easy to cut, drill, or process into custom shapes.

Many epoxy resin laminated sheet suppliers provide CNC machining services to produce custom epoxy laminated insulation parts, tailored to transformer designs.

Conclusion

Epoxy laminated sheets for transformer insulation are essential materials that provide reliability, durability, and performance in modern power equipment. From 3240 epoxy sheets to FR4 insulation sheets, choosing the right grade ensures long service life and safe operation of transformers.

If you are looking for a trusted epoxy resin laminated sheet supplier, make sure to consider not only the technical specifications but also the ability to provide custom epoxy laminated insulation parts for your project needs.

By understanding the applications and selection criteria, you can confidently choose the best epoxy laminated sheet for your transformer insulation system.