Prepreg DMD in Dry-Type Transformers: Properties, Applications, and Benefits

In modern power distribution systems, dry-type transformers are increasingly favored for their safety, environmental friendliness, and ease of installation. At the heart of their performance lies the insulation system, which ensures electrical reliability, thermal resistance, and mechanical stability. Among the many insulation materials, prepreg DMD stands out as a cost-effective and reliable solution.

What is Prepreg DMD Insulation?

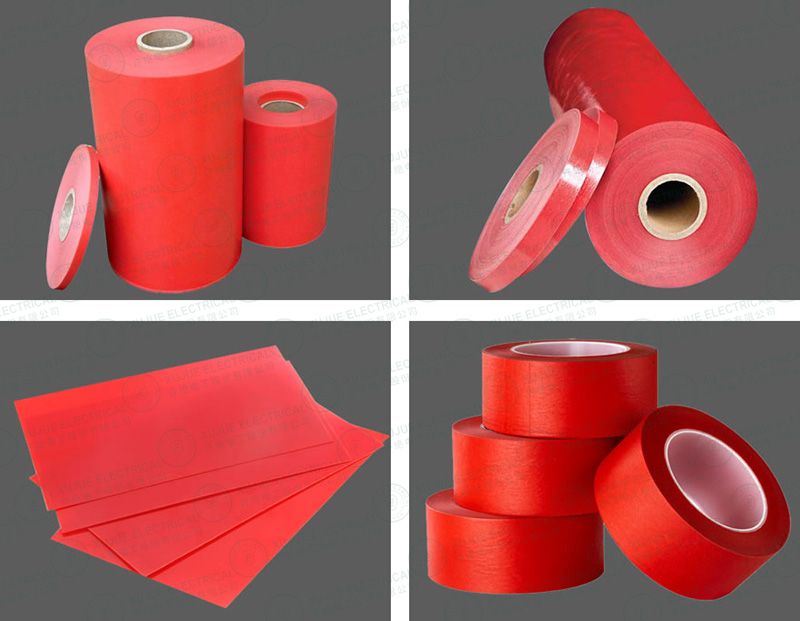

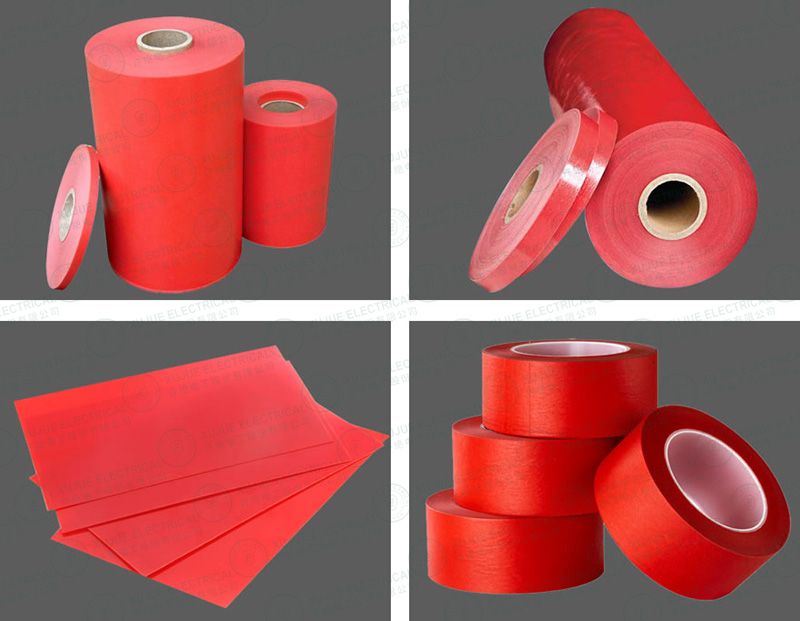

Prepreg DMD insulation for dry-type transformers is a three-layer composite made of:

• Polyester non-woven fabric (mechanical support and flexibility)

• Polyester film (high dielectric properties)

• Heat-resistant adhesive resin (impregnated for bonding strength)

This unique structure allows prepreg DMD to act as both an electrical insulation material and a bonding medium during transformer coil manufacturing.

Key Properties of Prepreg DMD

1. Excellent dielectric strength – protects windings against breakdown.

2. Thermal stability (Class B/F) – withstands 130–155°C operating conditions.

3. Strong bonding strength – after hot pressing, ensures secure adhesion of transformer coils.

4. Mechanical reinforcement – enhances winding integrity.

5. Cost-effective solution compared to advanced options like Nomex.

Applications of Prepreg DMD in Dry-Type Transformers

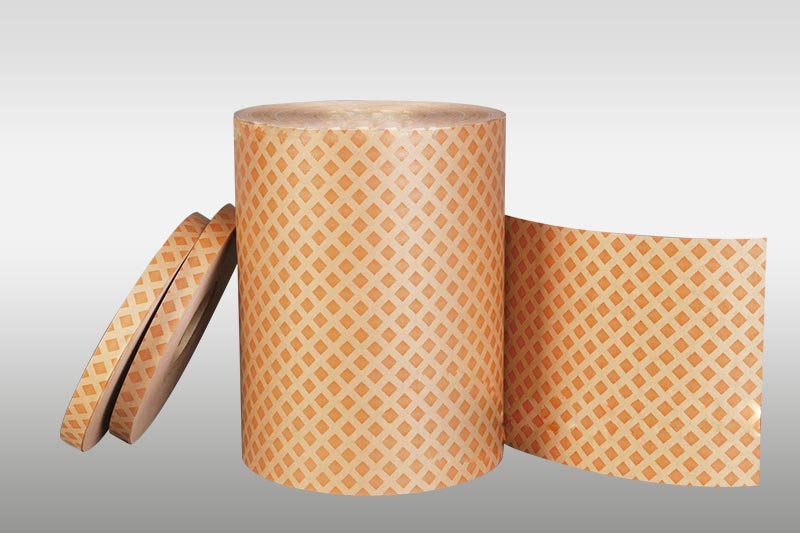

Prepreg DMD plays a dual role in transformer manufacturing: insulation and mechanical reinforcement. Major applications include:

♦ Layer insulation in transformer windings – prevents short circuits.

♦ Interlayer bonding strength in transformer coils – maintains stability under load fluctuations.

♦ End insulation and coil shaping – improves structural reliability.

♦ Dry-type transformer coil insulation material – ensures long-term safety and performance.

Why Choose Prepreg DMD for Transformer Insulation Systems?

Improved reliability – minimizes insulation failure.

Extended service life – handles long-term thermal and mechanical stress.

Enhanced safety – suitable for overload and high-demand conditions.

Economic advantage – offers the best balance of cost and performance.

Conclusion

As demand for dry-type transformer insulation materials grows in modern power networks, prepreg DMD is becoming an essential solution. With its high dielectric strength, bonding capability, and cost-effectiveness, it ensures transformer insulation system reliability and supports safe, efficient operation.

By integrating prepreg DMD insulation in transformer manufacturing, companies can achieve longer service life, fewer failures, and higher overall performance.