Why Electrical Laminated Wood Is Essential for Transformers?

In the world of power transmission and distribution, transformers play a vital role in ensuring the stable flow of electricity. Behind their reliability lies not only advanced design but also the careful selection of insulating and structural materials. Among these, electrical laminated wood stands out as an essential component, especially in medium- and high-voltage transformers.

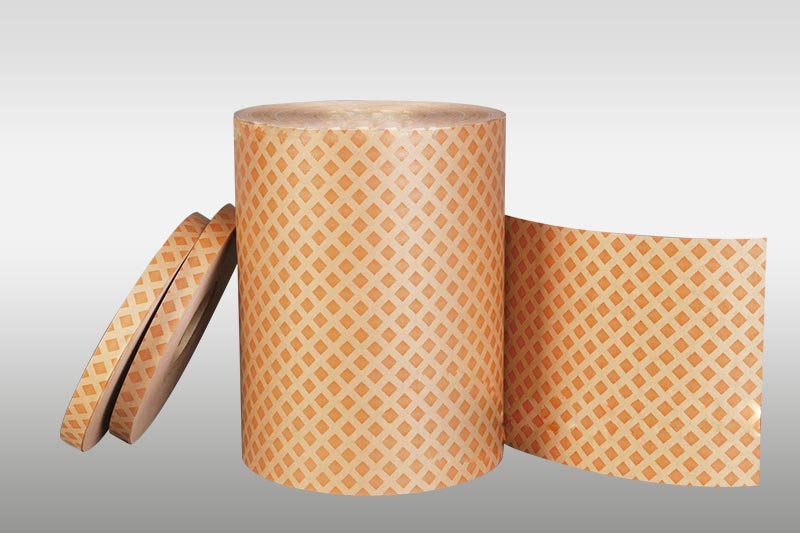

What is Electrical Laminated Wood?

Electrical laminated wood, sometimes called pressboard laminated wood or densified laminated wood,is made of good birch that is rotarily cut into thin wood layer and then dried, laminated and hot pressed.The result is a material with:

► High mechanical strength

► Excellent electrical insulation properties

► Low water absorption

► Dimensional stability under varying loads

These characteristics make laminated wood particularly suitable for transformer construction.

Key Roles of Laminated Wood in Transformers

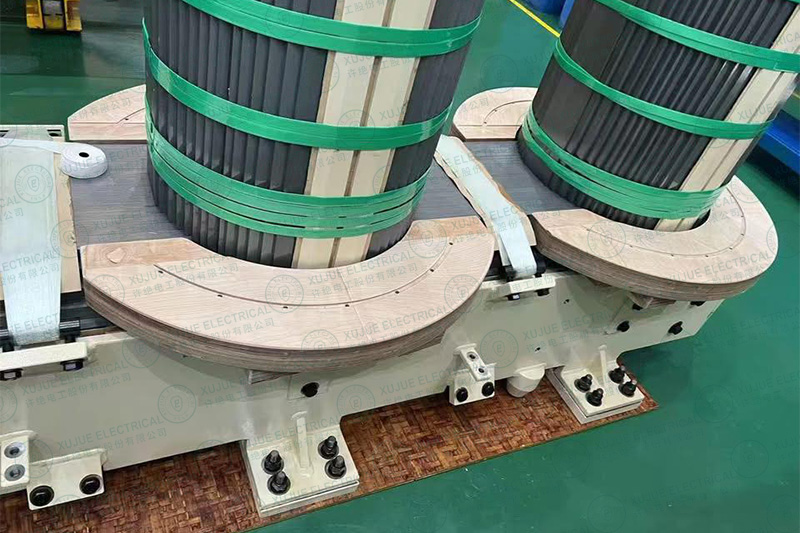

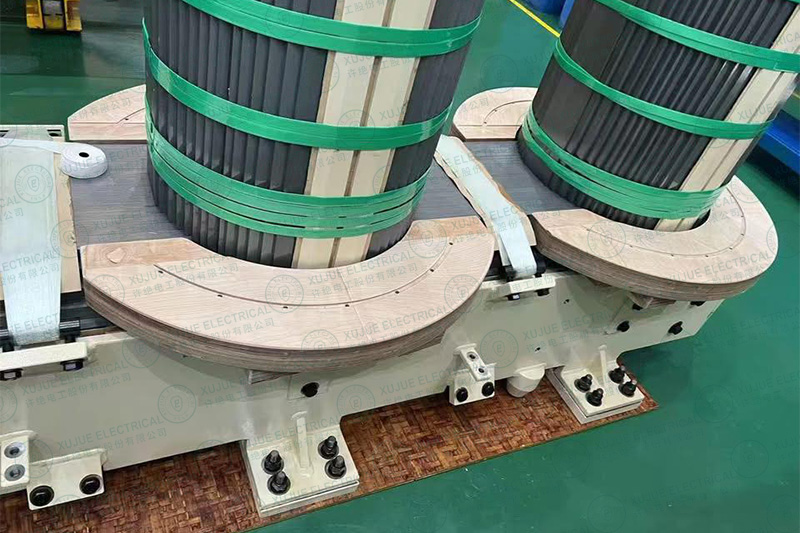

1. Mechanical Support

Transformers must withstand electrical, mechanical, and thermal stresses during operation. Laminated wood provides strong structural support for:

► Clamping and pressure rings

► Coil supports and spacers

► Lead supports and fasteners

Its high mechanical strength helps maintain winding alignment and prevents deformation under short-circuit conditions.

2. Electrical Insulation

As an insulating material, laminated wood offers a high dielectric strength, preventing electrical breakdown between components. It ensures that windings remain electrically isolated, which is essential for safe transformer operation.

3. Oil Compatibility

Laminated wood is highly compatible with transformer insulating oil. Instead of degrading, it absorbs oil and enhances its dielectric performance. This synergy extends the operational life of both the laminated wood and the transformer itself.

4. Thermal Resistance

Transformers operate under varying loads, which generate significant heat. Laminated wood maintains stability at elevated temperatures, resisting thermal aging and ensuring long-term reliability.

5. Vibration and Noise Reduction

Transformers often produce vibrations and humming sounds. Laminated wood has a natural damping effect, reducing noise and protecting windings from mechanical stress.

Advantages Over Alternative Materials

Compared with metals or plastics, laminated wood combines high strength, light weight, and insulation in one material. Unlike pure metals, it does not conduct electricity. Unlike plastics, it remains stable under oil immersion and high temperatures. This unique balance makes it irreplaceable in transformer applications.

Applications in Transformer Construction

Some common applications of laminated wood include:

► Clamping rings

► Top and bottom supports

► Spacer blocks and guide rails

► Fastening structures for windings

Each of these contributes to the overall safety, efficiency, and lifespan of transformers.

Conclusion

Electrical laminated wood is far more than just a structural material—it is a critical enabler of transformer reliability. By combining mechanical strength, electrical insulation, oil compatibility, and thermal resistance, it ensures transformers can operate safely and efficiently over decades of service.

As the demand for high-performance power equipment continues to grow, electrical laminated wood will remain an indispensable material in transformer engineering.