Top 5 Benefits of Bakelite Board in Motors & Transformers

In the world of electrical engineering, Bakelite boards have been a cornerstone insulation material for decades. Known for their high mechanical strength, excellent heat resistance, and superior electrical insulation, they are widely used in motors, transformers, switchgear, and other electrical devices. This article explores the top 5 benefits of Bakelite boards, with technical data and practical insights for engineers and designers.

1. Excellent Electrical Insulation

Bakelite boards are thermosetting phenolic resin-based insulation sheets with high dielectric strength, typically ranging from 15 to 25 kV/mm depending on thickness and manufacturing grade. This property ensures minimal current leakage and prevents short circuits in motors and transformers. For example:

• A 3 mm thick Bakelite sheet can safely withstand 45–60 kV in standard testing conditions.

• Operating voltage compatibility up to 1,000 V AC or DC is common for industrial applications.

This makes Bakelite ideal for applications requiring high-voltage insulation reliability.

2. High Mechanical Strength

Mechanical durability is critical in electrical equipment exposed to vibration, stress, and load cycling. Bakelite boards offer tensile strength up to 90–100 MPa and flexural strength of 110–120 MPa. These characteristics ensure that the insulation maintains structural integrity over time, reducing deformation or cracking in motors and transformers, even under heavy operational stress.

3. Superior Heat Resistance

Bakelite boards exhibit excellent thermal stability, typically operating in the range of -60°C to +150°C. Some high-grade boards can even withstand continuous operation at 160°C without significant deterioration. This ensures insulation reliability in motors and transformers that generate heat during long-term operation:

• Thermal conductivity: ~0.2 W/m·K (helps dissipate heat moderately)

• Heat deflection temperature: 150–160°C

This high heat tolerance protects electrical equipment from thermal degradation and extends service life.

4. Chemical and Moisture Resistance

Industrial motors and transformers often encounter oils, lubricants, and humid conditions. Bakelite boards are resistant to most chemicals and absorb less than 0.5% water under standard testing conditions, which prevents swelling, corrosion, or insulation breakdown. This ensures:

• Consistent dielectric performance in humid environments

• Extended lifespan in oil-immersed or moisture-prone applications

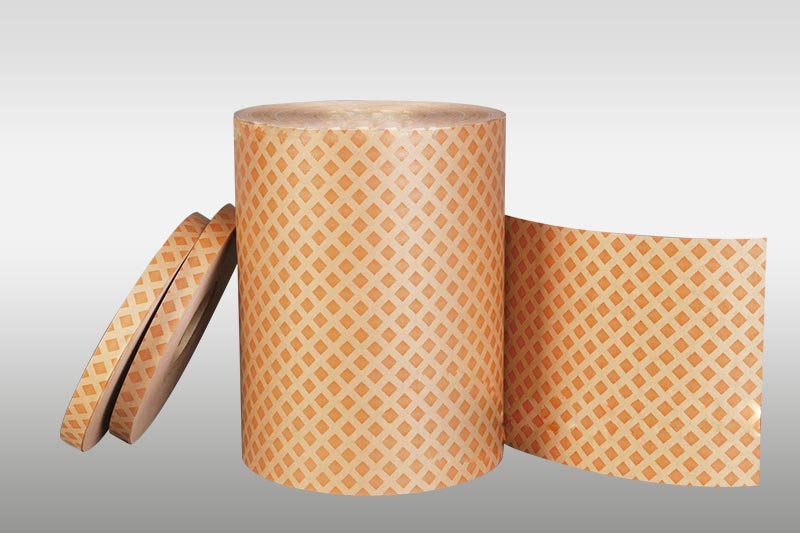

5. Versatility and Ease of Fabrication

Bakelite boards can be machined, drilled, or cut to custom dimensions with minimal risk of cracking. They are available in various thicknesses (1–20 mm) and sizes (up to 1,200 × 600 mm sheets). This adaptability allows engineers to design insulation for:

• Motor slots and windings

• Transformer cores and coil spacers

• Switchgear panels and insulating supports

Custom fabrication capability ensures precise fit and optimal performance in specialized equipment.

• Improved safety and reliability

• Reduced maintenance and downtime

• Extended service life of electrical equipment

XuJue Bakelite boards, for example, are manufactured under strict quality standards, ensuring consistent dielectric strength, thermal performance, and mechanical reliability. Selecting high-quality Bakelite boards is a smart choice for engineers and designers seeking long-lasting and efficient insulation solutions.