How to Extend the Lifespan of Bakelite? A Complete Guide to Maintenance and Care Tips

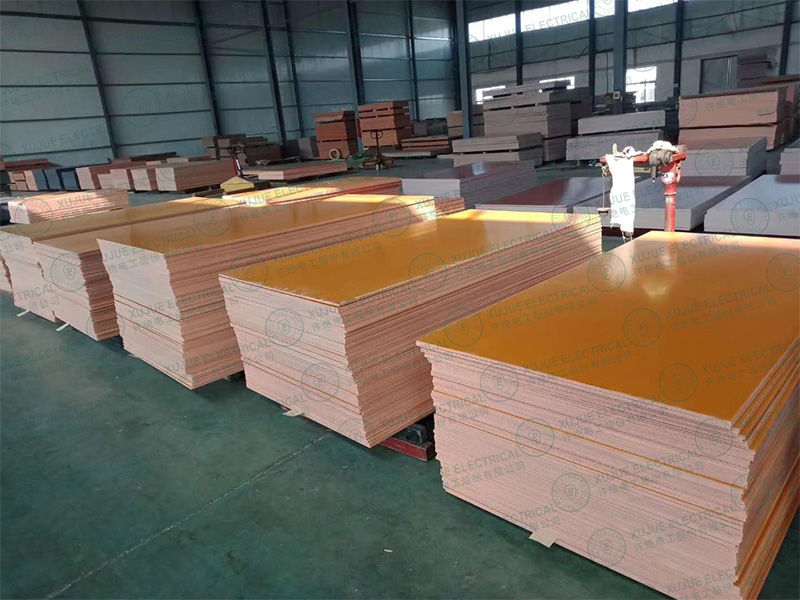

Bakelite, one of the earliest synthetic plastics, is widely used for electrical insulation, industrial machinery parts, household products, and collectible items. Known for its heat resistance, mechanical strength, and electrical insulating properties, Bakelite can last for decades if properly maintained.

In this guide, we’ll cover how to care for Bakelite, including cleaning tips, environmental precautions, and storage methods, so you can extend the lifespan of Bakelite products effectively.

1. What Makes Bakelite Durable Yet Vulnerable?

Bakelite has excellent performance in electrical and thermal applications, but it does have weaknesses.

• Strengths: High resistance to heat, strong insulating ability, dimensional stability.

• Weaknesses: Sensitive to moisture absorption, UV light, and physical impact.

Understanding these factors helps you apply the right maintenance strategy.

2. Best Practices for Cleaning Bakelite

Keeping Bakelite surfaces clean is the first step toward long-lasting performance.

• Use a soft cloth: Wipe gently with a dry or slightly damp cloth.

• Mild soap for vintage items: Safe for removing dirt, followed by immediate drying.

• Avoid harsh chemicals: Solvents like alcohol or acetone may cause surface damage.

Tip: For vintage Bakelite collectibles, a polishing oil can restore shine without harming the material.

3. Environmental Care: Where to Place Bakelite Products

The environment has a direct impact on the longevity of Bakelite.

• Moisture protection: Keep Bakelite away from water and high humidity.

• UV protection: Store in shaded areas to prevent discoloration and degradation.

• Temperature control: Avoid continuous exposure to extreme heat, even though Bakelite is heat resistant.

4. Prevent Mechanical Damage

Bakelite is durable but brittle compared to modern plastics.

• Handle with care: Avoid dropping or applying sudden pressure.

• Secure installation: For industrial or electrical applications, mount Bakelite parts firmly.

• Regular inspections: Look for small cracks and replace damaged pieces before they fail.

5. Use Protective Coatings (Optional)

Adding a protective layer helps Bakelite withstand harsh conditions.

• For industrial use: Thin varnishes or films protect against moisture and chemicals.

• For collectibles: Mineral oils or specialized polishes enhance both durability and appearance.

6. Safe Storage Guidelines

When Bakelite is not in use, follow these storage rules:

• Store in a dry, cool, and shaded environment.

• Use wrapping or padding to prevent scratches and cracks.

• Avoid stacking heavy items on top of Bakelite components.

7. Quick Maintenance Checklist

► Clean with a soft cloth, no harsh chemicals

► Keep away from moisture and UV exposure

► Protect from mechanical stress

► Apply protective polish or coatings if needed

► Store properly in dry, cool conditions

Conclusion

By following these Bakelite maintenance and care tips, you can extend the lifespan of Bakelite in both industrial applications and household products. Regular cleaning, proper storage, and preventive protection ensure that Bakelite remains durable, reliable, and valuable for years to come.

Whether you’re an engineer working with Bakelite electrical insulation components or a collector preserving vintage Bakelite items, these practices will help you keep this legendary material in top condition.