Insulation Materials in Dry-Type Transformers: Properties, Applications, and Future Trends

Introduction

Dry-type transformers are widely used in modern power systems due to their safety, reliability, and eco-friendly performance. Unlike oil-filled transformers, they rely heavily on solid insulation materials to ensure dielectric strength, thermal stability, and mechanical durability. Choosing the right insulation materials for dry-type transformers is critical for enhancing performance and extending service life.

This article explores the main types of dry-type transformer insulation materials, their properties, applications, and future development trends.

Epoxy Resin Insulation

Epoxy resin is one of the most important insulation materials in dry-type transformers. It is mainly used in cast-resin transformers, where windings are completely encapsulated with epoxy.

Key Properties:

• High dielectric strength and arc resistance

• Excellent thermal endurance (Class F/H)

• Moisture-proof and dust-proof performance

• Strong mechanical bonding with copper conductors

Applications:

• Cast resin distribution transformers

• Encapsulation of windings and coils

• Components requiring high-voltage insulation

Epoxy resin insulation ensures fire safety, low partial discharge, and long-term reliability, making it a cornerstone material for dry-type transformer manufacturing.

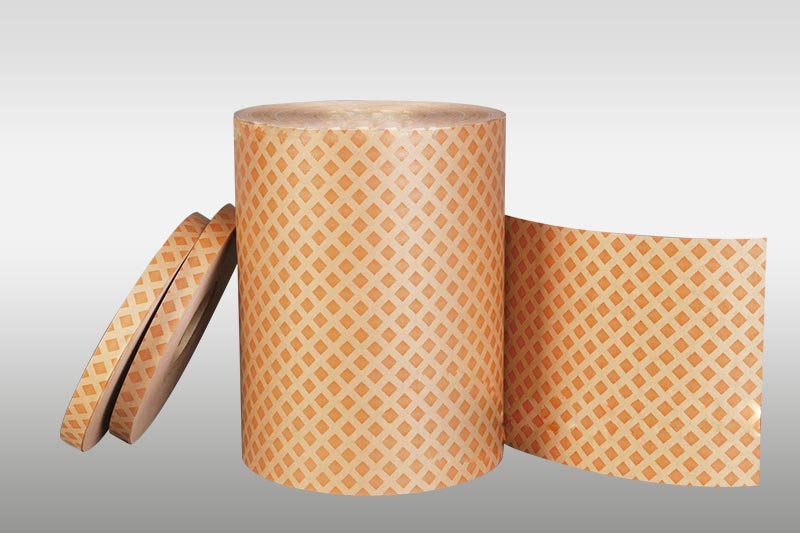

Nomex Insulation Paper

Nomex Paper is made from a polymerof two forms of aromatic polyamides.

Key Properties:

• High-Temperature Resistance: NOMEX paper has a temperature resistance rating of up to H (180°C), making it suitable for high-load operating environments.

• Mechanical Properties: The calendering process ensures a high degree of surface flatness, making it suitable for open structures requiring both insulation and mechanical strength.

Applications:

• Used for interlayer insulation of high and low voltage windings to prevent interturn breakdown

• Nomex paper is used as an insulating pad between the winding and the core or between the winding and the clamp to prevent partial discharge and electrical breakdown

Epoxy Glass Fiber Laminates (G10, G11, FR4)

Epoxy glass fiber laminates, including G10, G11, and FR4, combine epoxy resin with fiberglass cloth, offering outstanding electrical and mechanical performance.

Key Properties:

• High mechanical strength and dimensional stability

• Excellent dielectric strength

• Thermal resistance up to Class H (for G11)

• Flame-retardant performance (FR4 grade)

Applications:

• Insulating supports and barriers in transformers

• Structural components such as clamps, pads, and slots

• High-voltage insulation parts requiring strong mechanical load-bearing capacity

Due to their durability and versatility, epoxy laminates are widely used in high-performance dry-type transformers and switchgear.

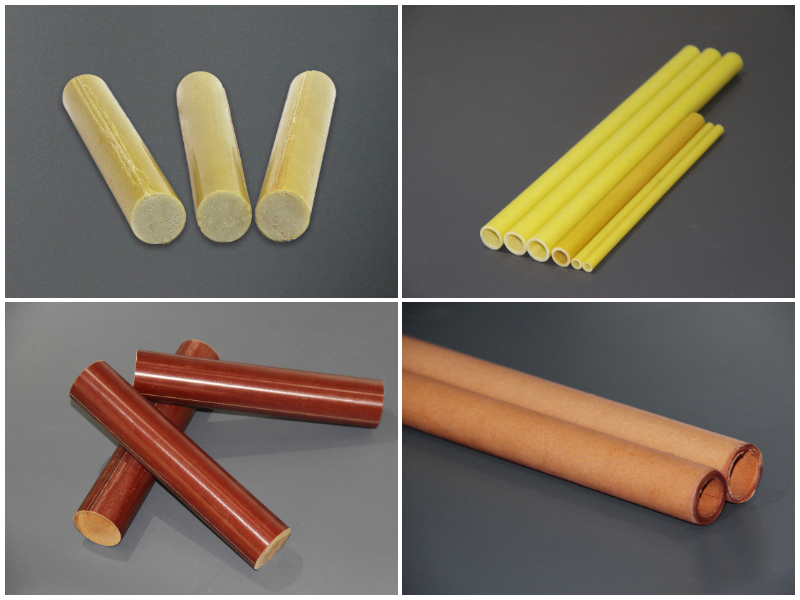

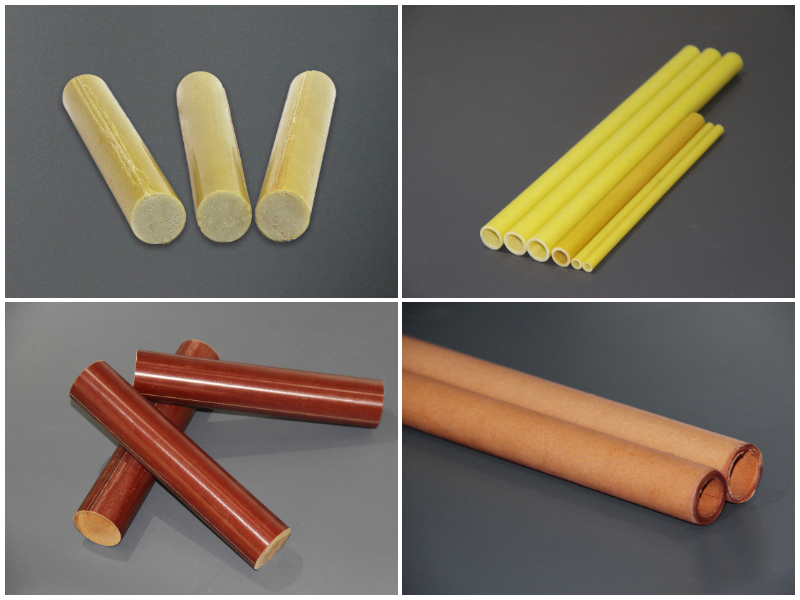

Insulating Tubes and Rods

Insulating tubes and rods, made of epoxy fiberglass or phenolic materials, are essential for structural and electrical insulation.

Key Properties:

• Good dielectric strength

• Mechanical rigidity and machinability

• Resistance to environmental stress

Applications:

• Spacer rods, insulating bolts, and bushings

• Mechanical reinforcement of transformer windings

• Customized machined insulation components

These components enhance both electrical safety and structural stability in transformer assemblies.

Comparative Overview of Insulation Materials

|

Material |

Dielectric Strength |

Thermal Class |

Mechanical Strength |

Typical Applications |

|

Epoxy Resin |

Excellent |

F / H |

High |

Cast resin encapsulation, windings |

|

Nomex |

Good |

H |

High |

Interlayer insulation,insulation barrel |

|

Epoxy Glass Fiber (G10/G11/FR4) |

Excellent |

F / H |

Very High |

Supports, barriers, slots |

|

Insulating Tubes & Rods |

Good |

B / F |

High |

Spacers, bushings, machined parts |

Future Trends in Dry-Type Transformer Insulation

As energy systems evolve, insulation materials for dry-type transformers are expected to meet higher requirements:

• Higher thermal endurance: New epoxy formulations and nano-composites improve heat resistance.

• Eco-friendly insulation: Materials with lower environmental impact and recyclability are gaining attention.

• Enhanced partial discharge resistance: Advanced resins and laminates reduce electrical stress.

• Customized solutions: More demand for CNC-machined epoxy boards, tubes, and composite parts for precision fit in transformers.

These innovations will further improve safety, efficiency, and sustainability in transformer applications.

Conclusion

The performance of dry-type transformers relies significantly on the choice of insulation materials. Epoxy resin, insulation paper, epoxy laminates (G10, G11, FR4), and insulating tubes/rods each play a vital role in ensuring dielectric safety, thermal stability, and mechanical strength.

With the continuous advancement of epoxy composites and eco-friendly insulation solutions, dry-type transformers will become even more reliable, efficient, and adaptable to modern power system demands.