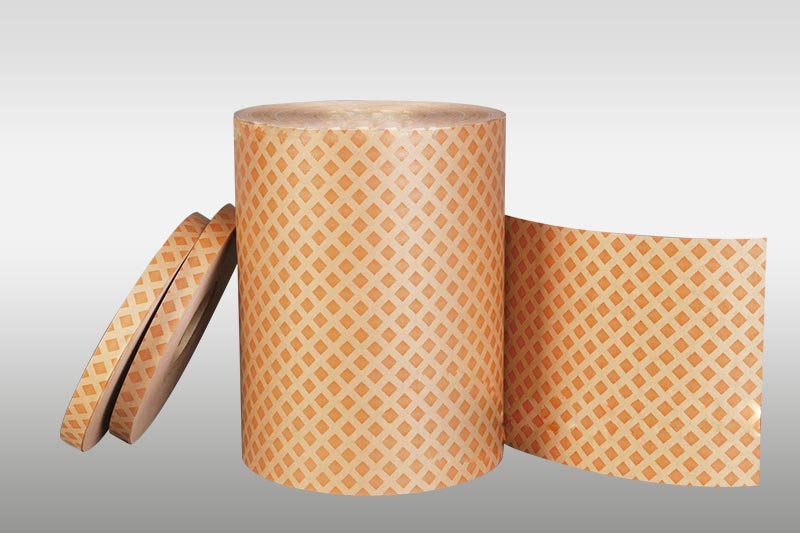

When it comes to electrical insulation, safety, durability, and efficiency are top priorities. Among the wide range of insulation materials available, flexible crepe paper tubes stand out as a proven and cost-effective solution. These tubes, made from high-quality cellulose crepe paper, are widely used in transformers, motors, and other electrical equipment.

In this article, we explore the advantages of crepe paper tubes, why they are widely adopted, and how they contribute to reliable power system operation.

Excellent Electrical Insulation Performance

XuJue crepe paper tubes have excellent dielectric strength. They are made of longer pure wood pulp fibers and can effectively withstand high electrical stress.

• In dry-type transformers, they ensure stable insulation.

• In oil-immersed transformers, they are compatible with insulating oils, enhancing dielectric properties.

This reliability makes crepe paper tubes an ideal choice for high-voltage insulation systems.

Flexibility and Mechanical Strength

The unique wrinkled surface (“crepe”) gives these tubes flexibility with strength.

• They can bend and adapt to irregular shapes during installation.

• At the same time, they provide excellent tensile and compression resistance.

This balance of strength and flexibility ensures long-term stability inside motors and transformers.

High Absorption and Oil Compatibility

One key advantage is their oil absorption capacity.

• The crepe texture increases surface area, enhancing oil retention.

• This improves dielectric performance and helps withstand thermal cycling stress.

As a result, flexible crepe paper tubes perform exceptionally well in oil-immersed transformers under fluctuating loads.

Thermal Endurance

Electrical systems often operate under high temperatures. Crepe paper tubes maintain excellent thermal stability.

• Resistant to heat aging

• Reliable insulation even at elevated temperatures

This makes them a trusted material for transformers, traction motors, and high-voltage devices.

Ease of Processing and Installation

Crepe paper tubes are easy to process:

• Can be cut or shaped into various sizes

• Lightweight and simple to install

• Saves time and reduces labor costs

This practicality makes them highly attractive for manufacturers.

Cost-Effectiveness

Compared with many synthetic insulation materials, crepe paper tubes are economical.

• Deliver excellent performance at lower cost

• Enable large-scale production without compromising safety

This cost-performance balance is why they remain a preferred choice for the power industry.

Environmentally Friendly

Made from natural cellulose, crepe paper tubes are:

• Biodegradable

• Eco-friendly

• Aligned with modern sustainability goals

This environmental benefit adds value for companies committed to greener solutions.

Conclusion

In summary, flexible crepe paper tubes provide:

• High dielectric strength

• Flexibility and durability

• Thermal endurance

• Oil compatibility

• Cost-effectiveness

• Environmental benefits

These advantages make them indispensable in transformer and motor insulation systems, supporting safe and reliable power delivery worldwide.