Why Phenolic Laminates Are Essential in Motors and Transformers?

Phenolic laminates, also known as phenolic resin boards or phenolic sheets, are one of the most reliable insulating materials used in the electrical industry. Their excellent combination of mechanical strength, dielectric properties, and heat resistance makes them a preferred choice in demanding applications such as motors and transformers. This article provides a practical guide on how phenolic laminates are used in these two critical fields, highlighting their benefits, functions, and best practices.

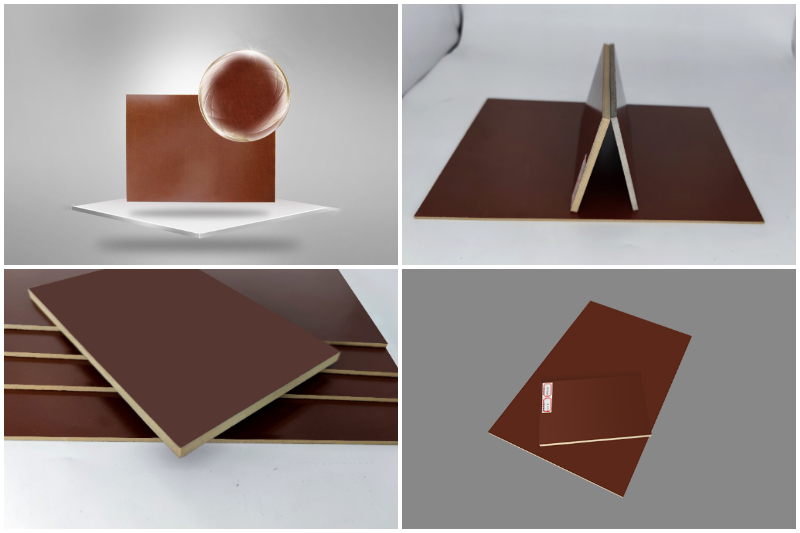

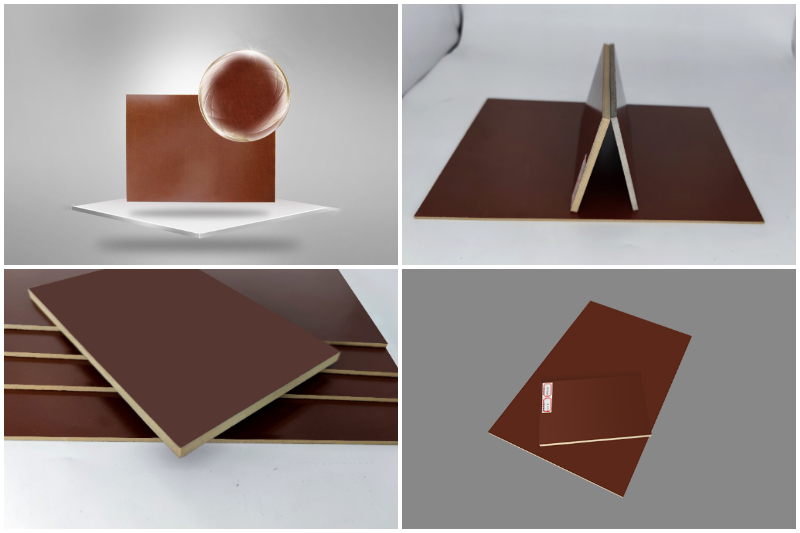

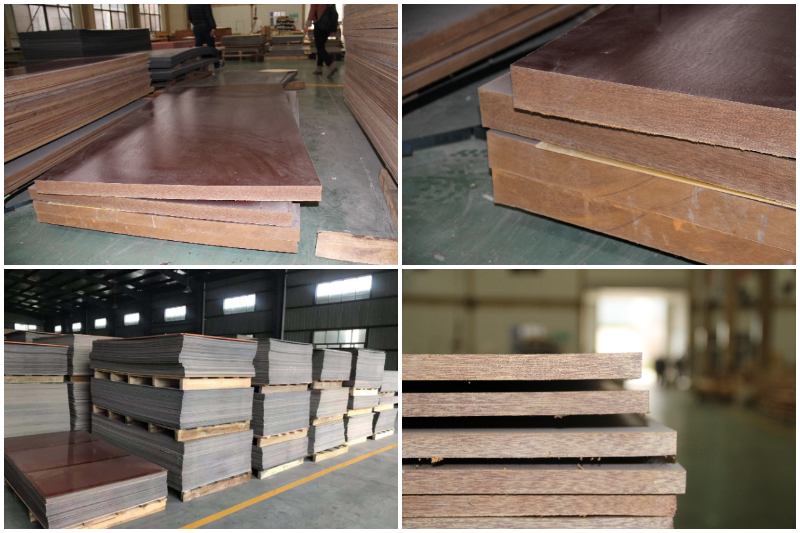

What Are Phenolic Laminates?

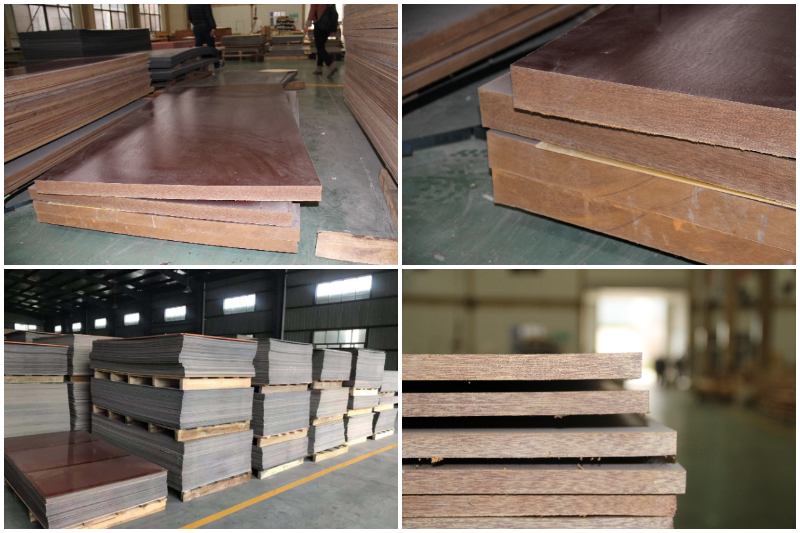

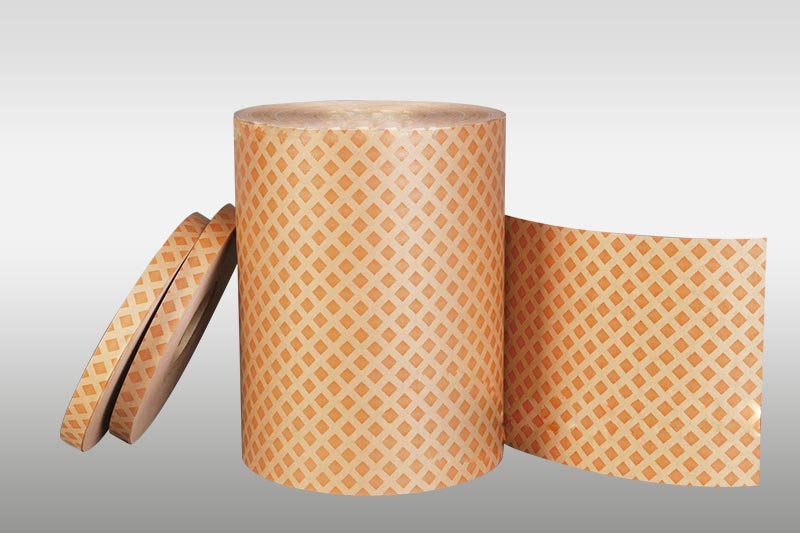

Phenolic laminates are manufactured by impregnating layers of paper, cotton fabric, or glass cloth with phenolic resin under high pressure and temperature. The result is a hard, durable, and stable insulating material with high mechanical strength and outstanding electrical performance. Depending on the reinforcement material, different grades of phenolic laminates are available, including phenolic paperboard and phenolic cotton cloth board.

Key properties include:

► High dielectric strength: ensures insulation reliability under electrical stress.

► Good mechanical strength: resists deformation and mechanical wear.

► Thermal stability: maintains performance under high operating temperatures.

► Moisture resistance: suitable for humid working environments.

► These characteristics explain why phenolic laminates are widely adopted in the production of electrical machines and power equipment.

Applications in Motors

Motors require insulating materials that can withstand mechanical vibration, heat, and electrical loads. Phenolic laminates serve multiple roles in this context:

► Slot Wedges and Insulation

Phenolic laminates are cut into strips and used as slot wedges in motor stators and rotors. They hold the copper windings firmly in place, preventing movement caused by electromagnetic forces. Their dielectric properties provide additional protection against short circuits.

► Support and Spacers

In larger motors, phenolic laminates are machined into spacers, end plates, and support parts. Their mechanical robustness ensures long-term dimensional stability under vibration and thermal cycling.

► Bearing Insulation

To reduce the risk of shaft current discharge through bearings, phenolic laminates can be used in insulation sleeves or bearing housings, prolonging motor life.

Applications in Transformers

Transformers require insulation that can withstand high voltage stress, thermal load, and oil immersion (in the case of oil-filled transformers). Phenolic laminates fulfill several important roles:

► Structural Insulation Components

Phenolic boards are machined into clamping rings, spacers, and brackets, providing both mechanical support and electrical insulation.

► Oil-Resistant Applications

Phenolic cotton cloth laminates, in particular, are resistant to transformer oil. This makes them ideal for use in oil-filled transformers, where they retain mechanical and electrical performance over time.

► Terminal and Connection Insulation

Phenolic laminates are often fabricated into terminal boards and barriers to ensure safe separation of conductors and minimize the risk of flashover.

Advantages of Using Phenolic Laminates in Electrical Equipment

► Cost-effectiveness: Phenolic laminates offer a balance of performance and affordability compared to other high-performance insulation materials.

► Machinability: They can be easily cut, drilled, and machined into complex shapes, making them adaptable for custom motor and transformer designs.

► Durability: Their resistance to heat, mechanical stress, and electrical breakdown ensures long service life.

Best Practices for Selection and Use

► When selecting phenolic laminates for motors or transformers, consider the following guidelines:

► Choose the right grade: Phenolic paperboard is suitable for low-voltage insulation, while phenolic cotton cloth laminates are recommended for high mechanical load or oil-immersed applications.

► Ensure precision machining: Accurate cutting and finishing are critical for slot wedges, spacers, and structural components to maintain performance and safety.

► Regular inspection: Over time, exposure to heat and stress may cause degradation. Routine inspection and timely replacement ensure reliability.

Conclusion

Phenolic laminates play a vital role in enhancing the safety, efficiency, and durability of motors and transformers. With their proven electrical insulation, mechanical strength, and adaptability, they remain an indispensable material in modern electrical engineering. By choosing the right type of phenolic laminate and applying best practices, manufacturers and engineers can achieve long-lasting performance and cost-effective solutions in power equipment.