The Practical Guide to Using Diamond Dotted Paper (DDP) in Transformers

In the world of electrical power equipment, particularly oil-immersed transformers, insulation plays a critical role in performance, reliability, and longevity. Among the insulation materials available today, Diamond Dotted Paper (DDP) stands out for its superior mechanical and electrical properties. This article explores the practical application of DDP in transformer manufacturing, and why it's preferred, supported by technical insights and globally recognized data.

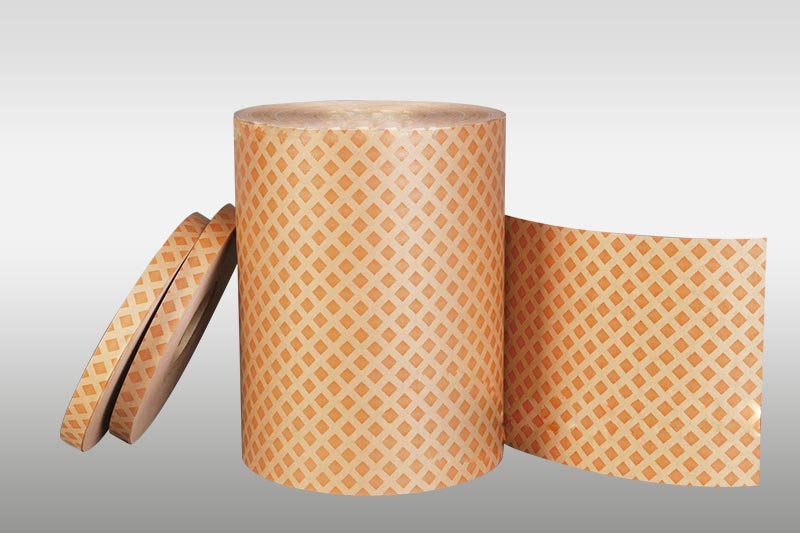

What Is Diamond Dotted Paper (DDP)?

Diamond Dotted Paper is a cellulose-based electrical insulation paper coated with heat-reactive epoxy resin in a diamond-shaped dot pattern on one or both sides. It is primarily used in layer insulation between coils in oil-immersed power and distribution transformers.

When the transformer is assembled and heated during the drying process, the epoxy resin melts and cures under pressure and temperature, forming a bonded, rigid insulation structure that resists movement, vibration, and electrical stress.

Application in Transformers

► Interlayer insulation between windings

► Spacer material to prevent short circuits

► Support for coil structures

During transformer operation, especially under high voltage and heat, insulation must maintain mechanical integrity and dielectric strength. DDP addresses these demands with its controlled bonding behavior and high stability in oil.

Research-Based Performance Metrics

According to industry data:

► Temperature Class: 105°C (Class A)

► Breakdown voltage: ≥ 4.0 kV in oil, ≥0.7 kV in air

► Bonding strength: ≥ 650 KPa at room temperature, ≥ 450 KPa at 100°C

► Oil absorption: ≥ 20%, ensuring full impregnation and gas discharge

► Tensile strength: Longitudinal ≥ 180 N/10mm, Transverse ≥ 230 N/10mm

Advantages of DDP in Transformer Design

1. Enhanced Mechanical Bonding

Once cured, the dotted resin forms a firm structure within the winding, reducing the risk of shifting during transport or thermal expansion.

2. Improved Dielectric Performance

The paper's structure, combined with resin curing, minimizes partial discharge and surface tracking.

3. Oil Compatibility

DDP is fully compatible with mineral transformer oils and silicone fluids. It doesn't degrade or react under prolonged immersion.

4. Thermal Endurance

Its thermal class supports continuous operation in standard oil-filled environments without compromising safety.

5. Clean Assembly & Easy Handling

The dot pattern prevents blocking (sticking), making roll feeding and layering during coil assembly smooth and efficient.

Backed by Research & Industry Usage

Leading transformer manufacturers and insulation specialists, including studies from IEEE Transactions on Dielectrics and Electrical Insulation, emphasize DDP’s role in improving insulation systems’ long-term reliability.

For instance, a study on aging performance under thermal stress (IEEE, 2020) showed that DDP-layered systems exhibited 35% fewer mechanical failures compared to standard kraft paper under identical test conditions.

Global Adoption & Sustainability

DDP is widely used in:

• Power transformers

• Distribution transformers

• Reactors and chokes

Modern DDP production, such as those provided by XuJue Electrical, ensures low environmental impact during manufacturing and disposal, aligning with global trends in eco-friendly insulation materials.

Conclusion

Diamond Dotted Paper is not just a material—it's a critical component for transformer insulation systems designed to meet the growing demand for grid reliability and energy efficiency.

With verified thermal, mechanical, and electrical performance, DDP helps manufacturers create more robust and long-lasting transformers.

If you're in the business of transformer manufacturing or repair, it's time to upgrade your insulation game with high-quality DDP from trusted suppliers like XuJue Electrical.