Insulation paper is a vital component of motors, ensuring durability, safety, and other performance. Among many insulation materials, DMD, NMN, and NHN stand out as the first choice due to their layered structure and heat resistance. But what are the differences between them? When should you choose one over the other? This article will explore the differences between these three types of insulation paper, their application scenarios in motors, and their importance.

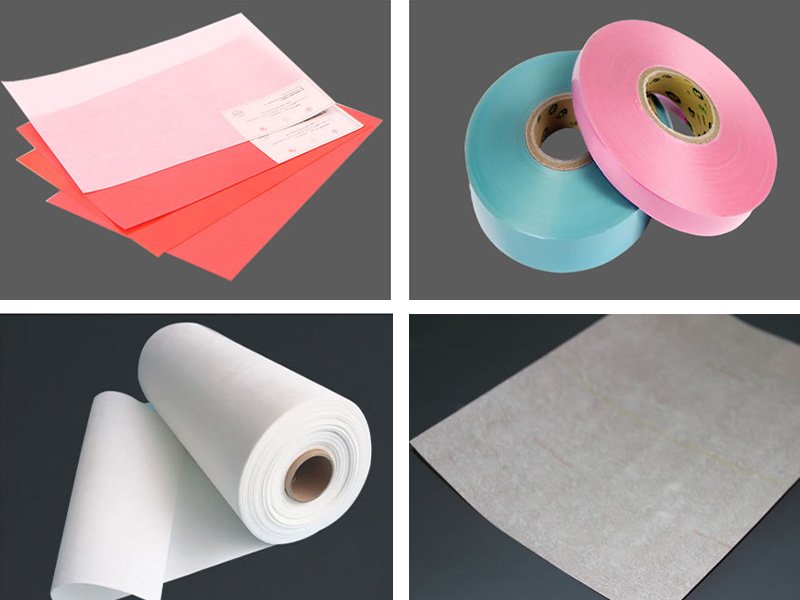

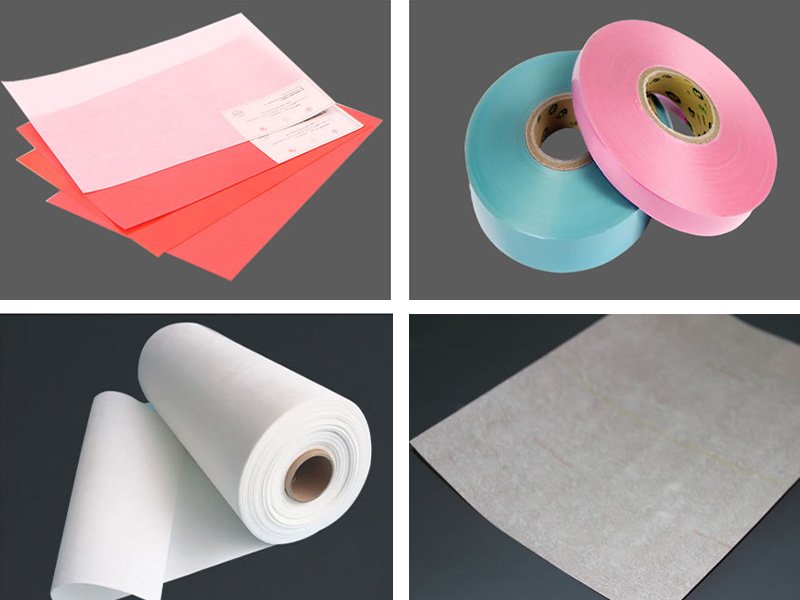

1. Understanding the Basics: What Are DMD, NMN, and NHN?

|

Material |

Structure |

Thermal Class |

Typical Application |

|

DMD |

PET film + nonwoven polyester (on both sides) |

Class B/F (130°C/155°C) |

Low/medium-voltage motors |

|

NMN |

PET film + Nomex® paper (on both sides) |

Class H (180°C) |

High-efficiency and inverter-driven motors |

|

NHN |

Polyimide film + Nomex® paper (on both sides) |

Class H(180°C) |

High-temperature, aerospace-grade motors |

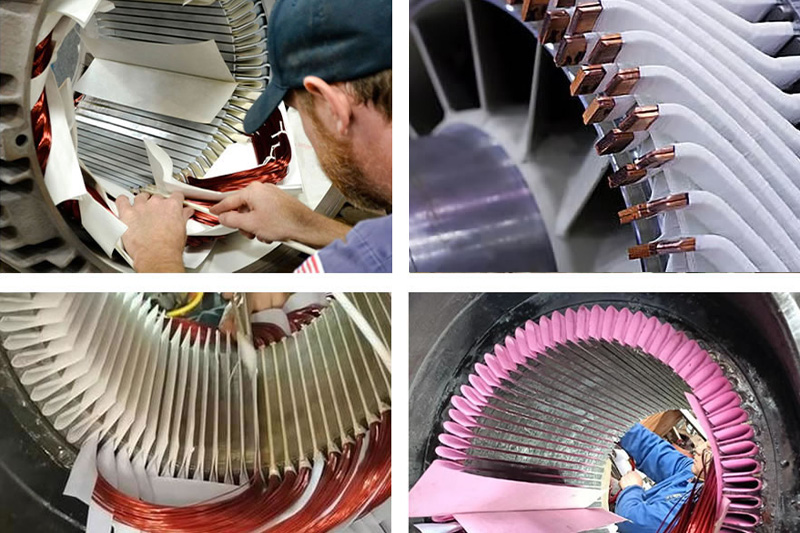

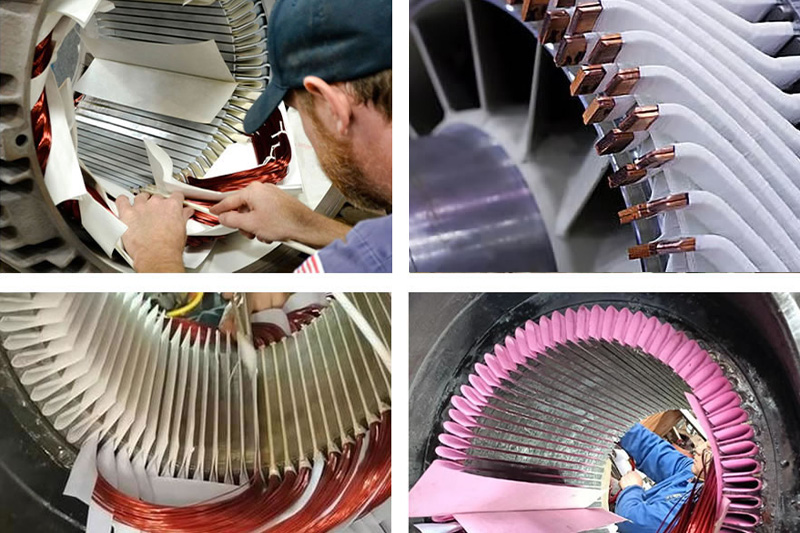

2. Application in Electric Motors

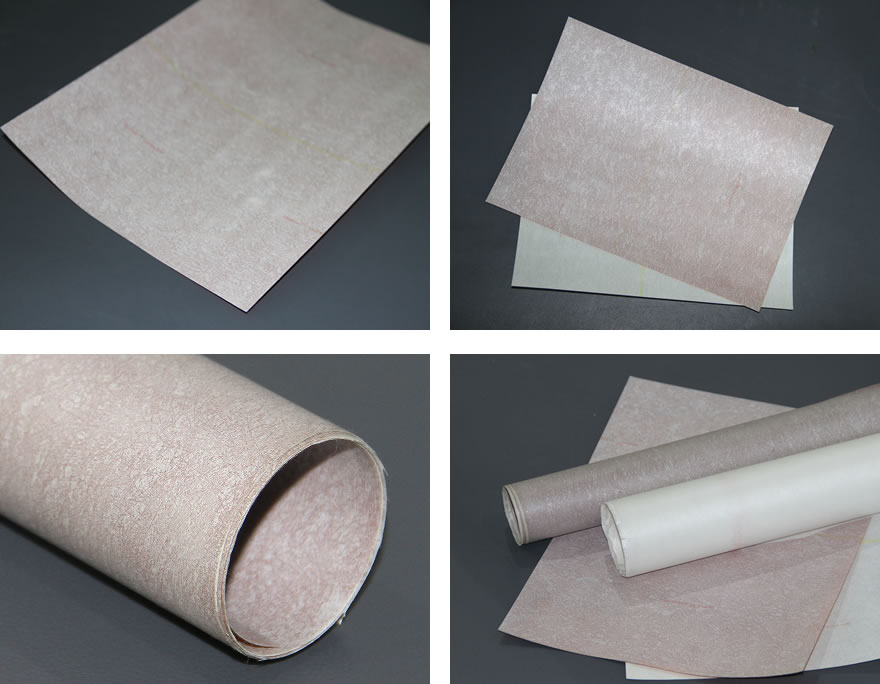

► DMD Insulation Paper

• Use Case: Slot liners, interlayer insulation, and phase insulation in low- to mid-power motors.

• Advantages:

• Economical

• Good mechanical strength

• Suitable for automated slot insertion

• Why Choose DMD: Ideal for standard induction motors, fan motors, and appliances where thermal loads are moderate.

► NMN Insulation Paper

• Use Case: Slot insulation in frequency-controlled motors, servo motors, and high-speed motors.

• Advantages:

• Excellent dielectric strength

• Better thermal stability (Class H)

• High reliability in fluctuating environments

• Why Choose NMN: Its Nomex® layers provide superior heat resistance and aging properties, especially important in modern motors where inverter spikes and overheating are common.

► NHN Insulation Paper

• Use Case: High-performance motors in aerospace, wind turbines, and EV traction systems.

• Advantages:

• Outstanding thermal endurance

• High dielectric strength and chemical resistance

• Durable under long-term electrical stress

• Why Choose NHN: For extreme environments where continuous high temperature and long lifecycle are required, NHN is the gold standard.

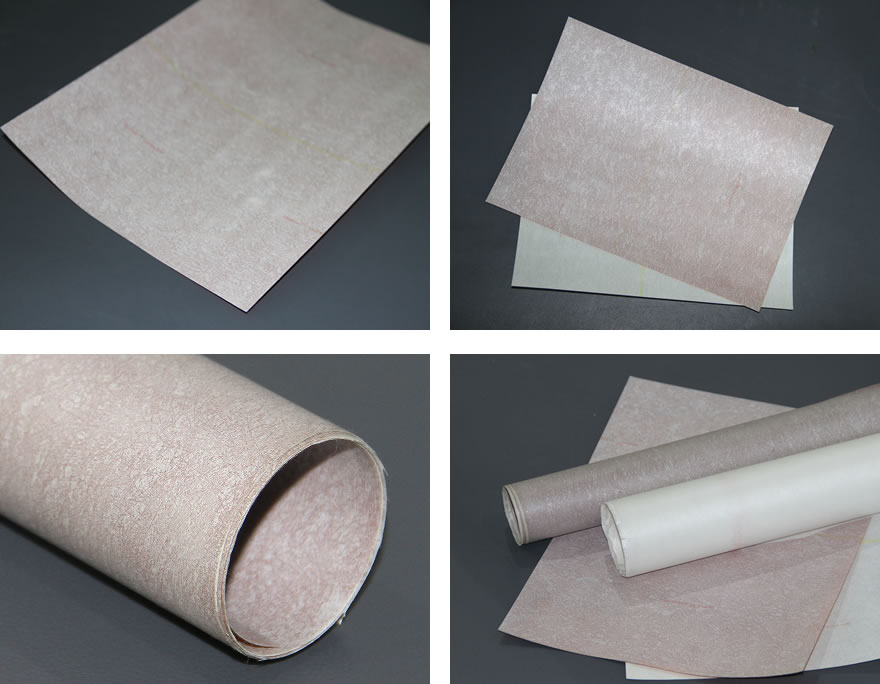

3. Key Differences: What Sets Them Apart?

|

Feature |

DMD |

NMN |

NHN |

|

Insulating Film |

Polyester (PET) |

Polyester (PET) |

Polyimide (Kapton® equivalent) |

|

Outer Layers |

Non-woven polyester |

Nomex® |

Nomex® |

|

Thermal Rating |

155°C (Class F) |

180°C (Class H) |

180°C (Class H) |

|

Cost Level |

Low |

High |

High |

|

Use Environment |

Standard |

High-speed/high-temp |

Harsh/extreme |

4. Choosing the Right Material: What Should You Consider?

When selecting insulation paper for motor design, the following factors are critical:

• Thermal load: Higher thermal class is required for motors operating under continuous load.

• Voltage spikes & inverter use: NMN or NHN are preferable for motors driven by VFDs (variable frequency drives).

• Budget and volume: DMD offers a cost-effective option for large-scale production of standard motors.

• Mechanical needs: NHN delivers the best long-term insulation under mechanical vibration and heat cycles.

Conclusion

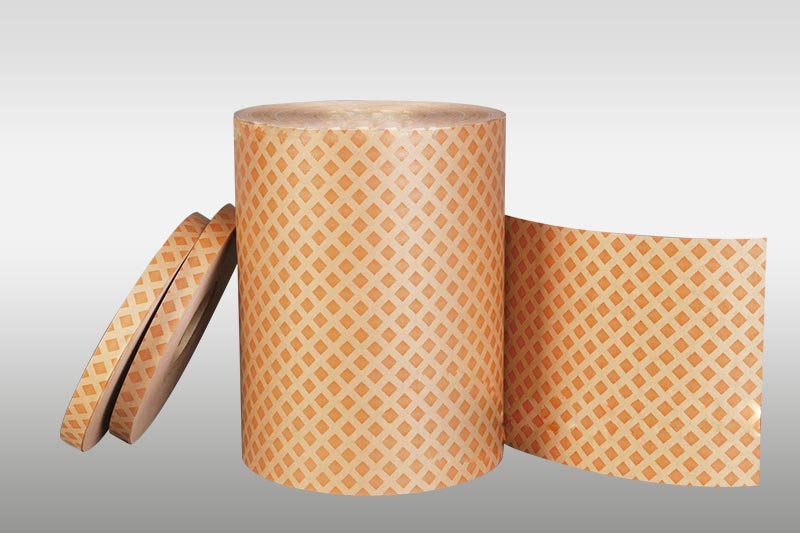

Whether you’re designing motors for industrial automation, renewable energy, or consumer appliances, the right insulation paper can directly impact performance, durability, and safety.

• Use DMD for standard efficiency at low cost.

• Choose NMN for inverter-duty motors with elevated performance.

• Select NHN when nothing less than extreme thermal and electrical endurance will do.

Partner with XuJue Electrical, your trusted insulation material supplier, to ensure you get top-quality insulation customized to your motor’s needs—with international delivery, RoHS compliance, and expert technical support.