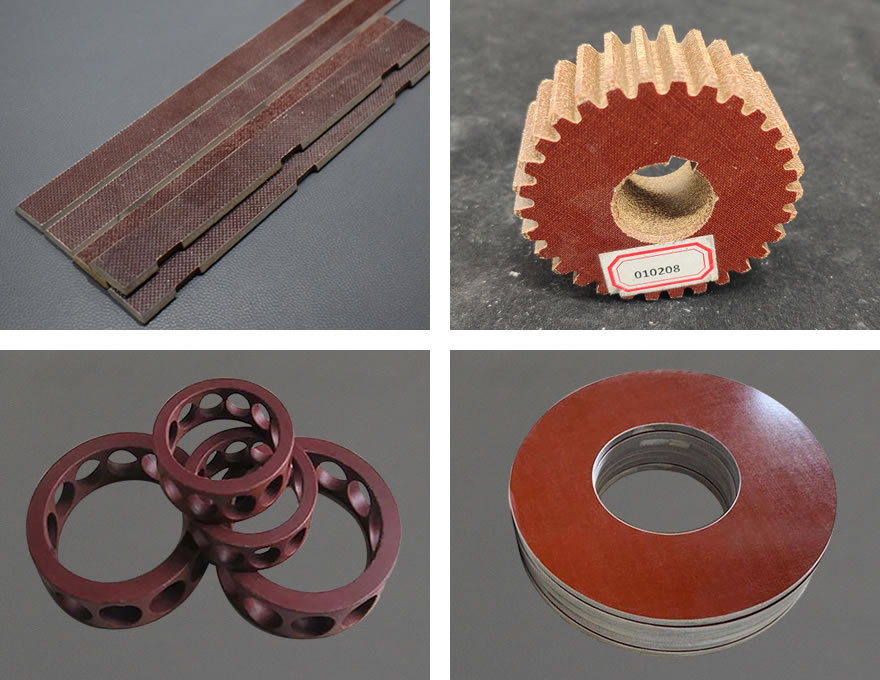

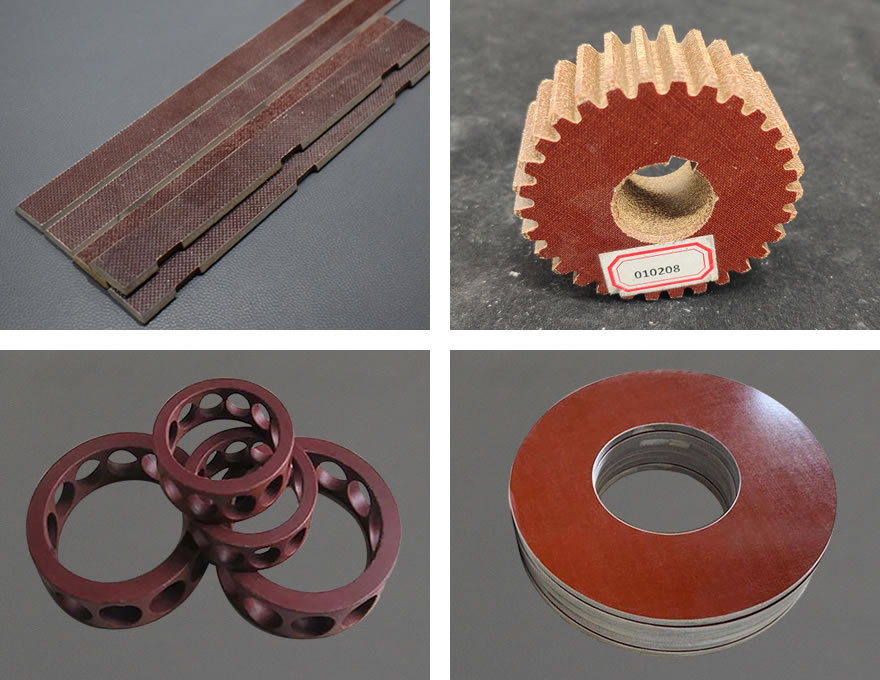

Phenolic machined parts for electrical and electronic applications

Introduction

Phenolic laminated sheets—have been a cornerstone in electrical insulation for decades. When processed into custom parts, phenolic machined components combine excellent electrical resistance with strong mechanical performance. This guide explores the key benefits, common applications, and considerations when using phenolic machining parts in electrical and electronic industries.

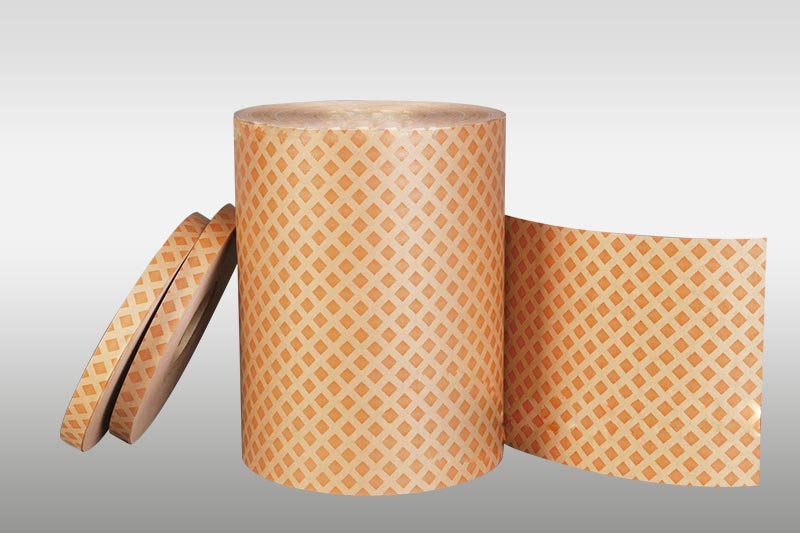

1. What Are Phenolic Laminated Sheets?

Phenolic laminated sheets are composite materials made by impregnating layers of paper or cloth with phenolic resin under heat and pressure. The result is a rigid, hard, and durable board with:

♦ High dielectric strength

♦ Excellent mechanical properties

♦ Good chemical and moisture resistance

Once processed through CNC machining, drilling, or milling, these sheets can be transformed into precision electrical components used across various sectors.

2. Key Benefits of Phenolic Machined Parts

Here’s why phenolic machining parts are preferred in electrical engineering:

♦ Electrical Insulation: Excellent dielectric strength makes them ideal for isolating electrical currents.

♦ Mechanical Strength: Resistant to compression and impact, suitable for structural applications.

♦ Dimensional Stability: Maintains shape and insulation in demanding environments.

♦ Cost-Effective: Lower production cost compared to advanced composites.

3. Common Applications in Electrical & Electronics

Phenolic machined parts are commonly used in:

♦ Switchgear components: Arc barriers, control panels, spacers

♦ Transformer insulation: Clamping parts, support brackets

♦ Motor applications: End laminates, insulation rings, slot wedges

♦ PCB fixture tooling: Jig bases, drilling fixtures

♦ Consumer electronics: Battery isolation plates, structural supports

Their machinability allows for customized production based on project requirements.

4. Why Choose Phenolic Machined Parts for Your Project?

Phenolic machining parts strike a balance between performance, safety, and cost. For high-volume or high-voltage environments, their insulating and mechanical reliability ensure safe operation. Compared to FR4 or G10, phenolic parts offer:

• Lower cost

• Easier processing

• Lighter weight

• Sufficient strength for medium-load applications

They are especially effective in low-to-medium voltage systems and thermal management applications.

5. Best Practices for Using Phenolic Parts

To ensure optimal performance, consider the following:

• Choose the right grade: Paper-based (e.g., 3021) for electrical insulation, cloth-based (e.g., 3025) for mechanical load-bearing.

• Ensure precision machining: CNC cutting ensures tight tolerances and clean edges.

• Avoid prolonged exposure to high humidity, though phenolic is relatively moisture resistant.

Conclusion

When it comes to safe, affordable, and efficient insulation materials, phenolic laminated machined parts remain a go-to choice for manufacturers and electrical engineers worldwide. Whether you’re designing switchgear, motors, or industrial transformers, phenolic parts from trusted manufacturers like XuJue Electrical can meet your custom requirements with speed and precision.