Key Applications and Advantages of Electrical Laminated Wood in Transformers

Introduction

Electrical laminated wood, also known as laminated densified wood, is a high-performance insulation and structural material widely used in power transformers. Made from layers of wood veneers impregnated with resin and compressed under high temperature and pressure, it offers excellent mechanical and dielectric properties. This article explores the critical roles, benefits, and performance factors of laminated wood in transformer construction.

1. What Is Electrical Laminated Wood?

Electrical laminated wood is a composite material engineered for electrical insulation and structural support. It is manufactured by bonding natural wood veneers—commonly beech or birch—with synthetic resins such as phenolic resin. This process enhances the material’s density, mechanical strength, and resistance to heat, oil, and moisture.

2. Core Applications in Transformers

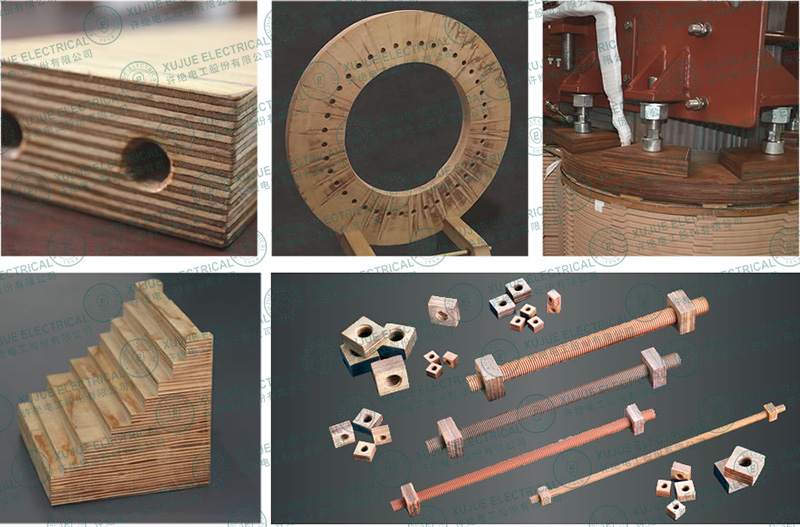

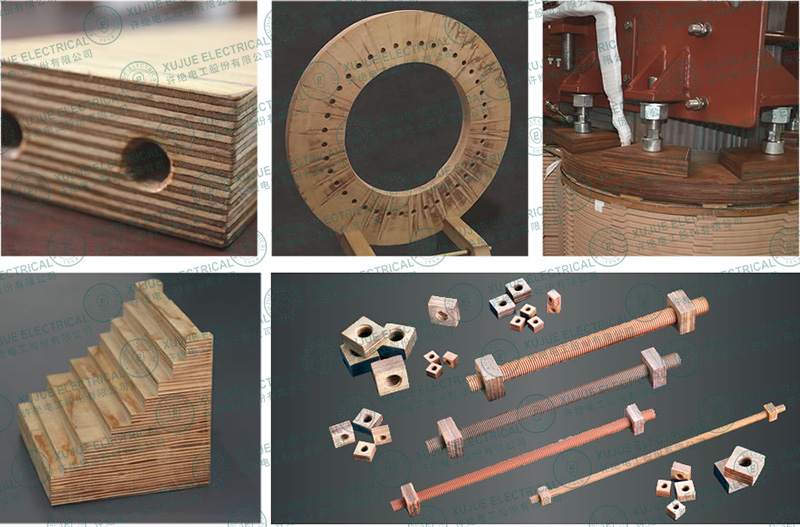

In oil-immersed power transformers, laminated wood is used in several key components:

• Clamping Rings & Pressure Rings

Provide mechanical support and uniform pressure to the transformer windings.

• Support Beams & Bracing Elements

Maintain structural stability within the transformer tank.

• Lead Supports & Spacers

Insulate and hold high-voltage leads in place, preventing displacement during operation or short circuits.

• Guide Rails & Coil End Braces

Help guide coil movement and protect windings during transport or inrush current events.

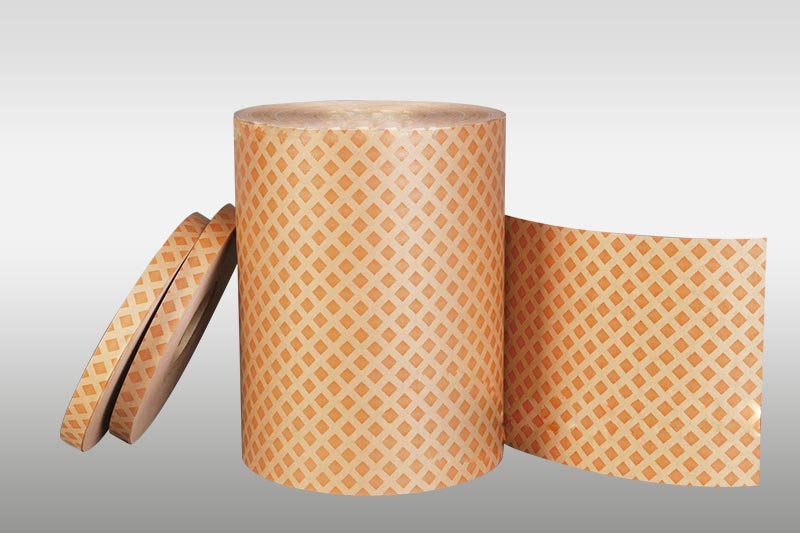

Laminated wood is often used in combination with other insulation materials like pressboard, epoxy glass laminates, and DDP paper for optimal electrical and thermal performance.

3. Advantages in Transformer Applications

Electrical laminated wood offers several benefits that make it a preferred choice for manufacturers:

► High Mechanical Strength

It can withstand significant compressive and tensile loads, ideal for components like clamping rings.

► Excellent Insulation Performance

Its low dielectric loss and high electrical resistance help prevent insulation breakdown in high-voltage environments.

► Thermal and Oil Resistance

The resin-treated wood resists degradation in transformer oil and can handle continuous temperatures up to 105–120°C.

► Dimensional Stability

Unlike untreated wood, laminated wood shows minimal swelling, shrinkage, or warping when exposed to oil or temperature changes.

► Lightweight & Easy to Machine

Compared to metal or glass laminates, it is easier to fabricate, drill, and shape for custom applications.

4. Sustainability & Cost-Effectiveness

Laminated wood is more eco-friendly than many synthetic insulation alternatives. Its wood-based core is renewable, and the manufacturing process consumes less energy than producing full plastic or metallic parts. Moreover, it offers an excellent performance-to-cost ratio, especially in large-scale transformer applications.

Conclusion

Electrical laminated wood is an essential material in transformer design, offering an unmatched combination of insulation strength, mechanical integrity, and sustainability. From supporting active parts to insulating high-voltage conductors, its role is vital in ensuring transformer reliability, safety, and longevity. As energy demands grow, choosing the right insulating material becomes critical—and laminated wood continues to prove its value across the power industry.