Application Guide of Diamond Dotted Paper (DDP) in Oil-Immersed Transformers

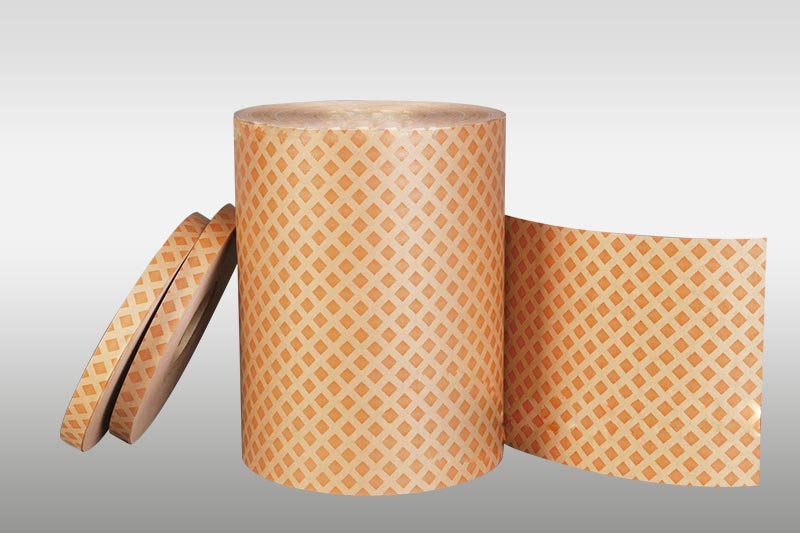

Diamond Dotted Paper (DDP) is a widely used insulating material in oil-immersed transformers due to its outstanding mechanical and electrical properties. It is a type of electrical insulation paper coated with heat-activated epoxy resin in a diamond-shaped dotted pattern. Once heated during transformer drying or assembly, these epoxy dots melt and bond the conductor layers tightly together, providing excellent mechanical strength and stability.

Why Diamond Dotted Paper Is Essential for Oil-Immersed Transformers

Oil-immersed transformers operate under high electrical stress and thermal cycles. The insulation materials used inside these transformers must be able to withstand these challenging conditions over long periods. DDP plays a vital role in this system by:

1. Providing high dielectric strength to prevent electrical breakdown.

2. Enhancing mechanical stability by bonding coil layers, reducing the risk of displacement during short-circuit forces.

3. Offering superior heat resistance, which helps maintain performance during temperature fluctuations.

4. Working seamlessly with transformer insulating oil to maintain insulation integrity.

The unique diamond pattern of epoxy resin dots allows oil to penetrate freely between paper layers before curing, which supports effective heat dissipation and oil circulation, improving the cooling of transformer windings.

Typical Applications of Diamond Dotted Paper

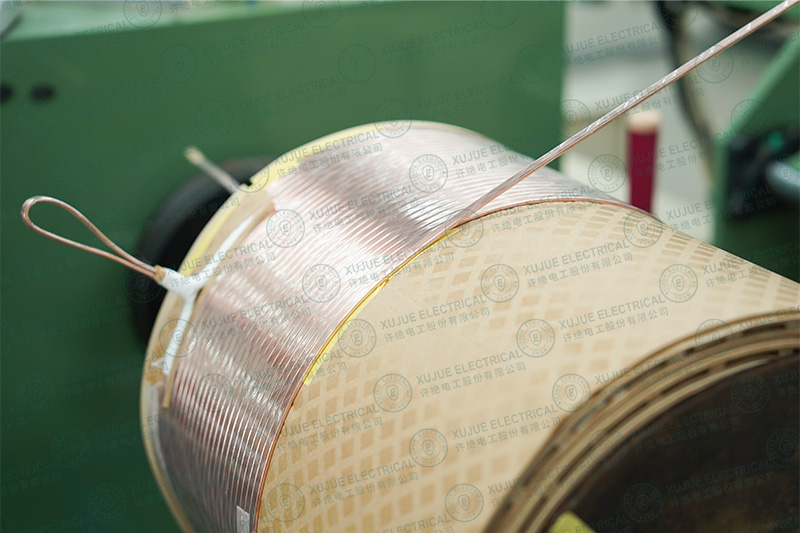

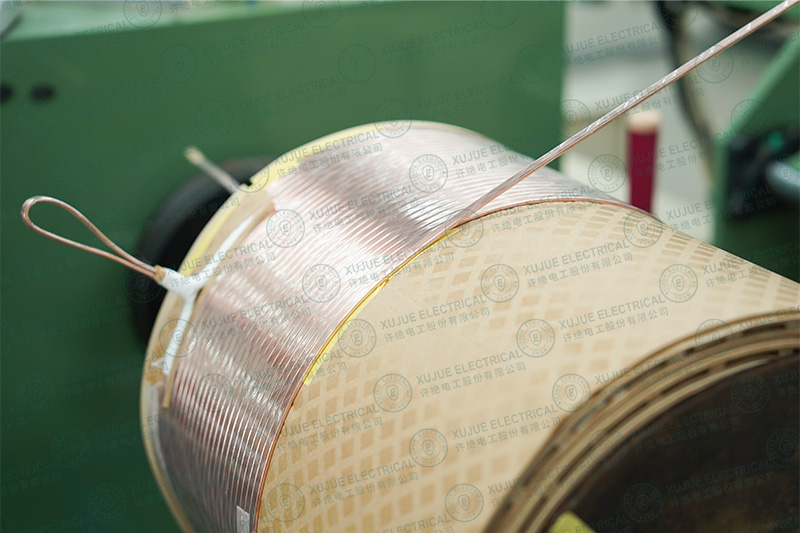

In oil-immersed transformers, Diamond Dotted Paper is primarily used for interlayer insulation of transformer coils and for conductor wrapping. Its main functions include:

• Interlayer insulation between transformer winding turns

• Insulating spacers in the transformer structure

• Layer-to-layer bonding in high-voltage coils

• Mechanical reinforcement of winding assemblies

These applications improve the transformer's ability to withstand short-circuit forces and mechanical vibrations, extending its service life.

Advantages of Using Diamond Dotted Paper

When properly applied, DDP offers several advantages compared to traditional insulation materials:

• Strong adhesion after curing: Epoxy dots melt and bond layers, preventing movement.

• High thermal class: Typically rated to Class A (105°C) or higher, depending on the base paper.

• Oil compatibility: Maintains insulation properties even in prolonged contact with transformer oil.

• Easy processing: Flexible for wrapping and forming during transformer manufacturing.

Best Practices for Applying DDP in Transformers

To achieve optimal results, manufacturers and engineers should follow these guidelines:

• Store DDP in a dry, controlled environment to avoid premature curing or moisture absorption.

• During transformer drying, apply sufficient heat and pressure to fully cure the epoxy resin dots.

• Avoid excessive bending or tearing of the paper before application.

• Follow precise insulation clearances based on transformer voltage class to maintain dielectric safety.

Conclusion

Diamond Dotted Paper is an essential insulating material that supports the safe, efficient, and long-lasting operation of oil-immersed transformers. By selecting high-quality DDP and applying it correctly, manufacturers can significantly improve the mechanical strength, dielectric performance, and reliability of their transformer products.

If you want to learn more about advanced transformer insulation materials like DDP, feel free to contact our technical team for expert guidance and customized solutions.