Top Uses of Phenolic Paper board in Electrical Insulation & Power Systems

Introduction

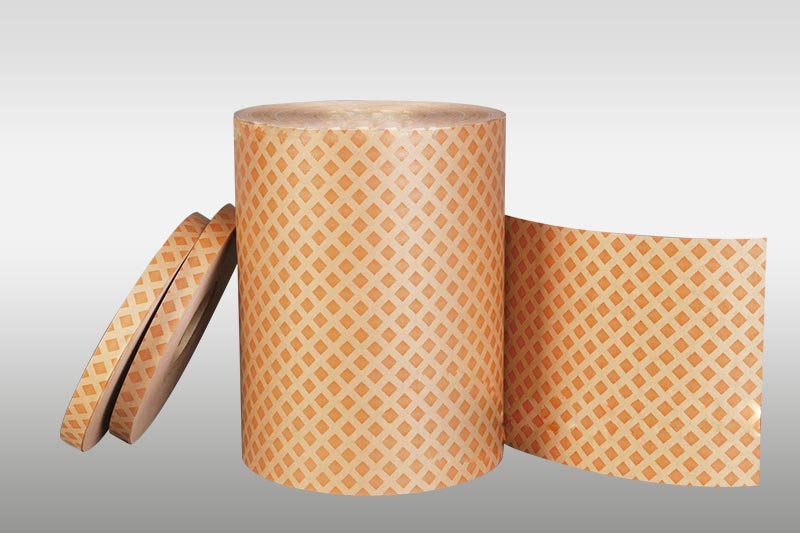

Phenolic paper sheet is a widely used insulating material in the electrical and power industries. Engineered by laminating layers of cellulose paper with phenolic resin under heat and pressure, this material offers excellent electrical insulation, mechanical strength, and cost-efficiency. From switchgear to transformer components, phenolic paper sheet plays a critical role in ensuring electrical safety and operational efficiency.

1. Transformer Insulation Components

One of the most common uses of phenolic paperboard is in oil-immersed and dry-type transformers. The material is used to produce support structures, insulation rings, spacers, and barriers due to its excellent dielectric strength and compatibility with transformer oils.

► Low moisture absorption

► Thermal stability up to 120°C

► Resistant to oil and aging

Phenolic laminated sheets can maintain their insulating properties for years, making them ideal for long-life transformer applications.

2. Switchgear & Control Panels

In medium- and high-voltage switchgear, phenolic paperboard serves as an internal arc barrier, mounting plate, or partition, separating conductive parts and protecting against arc flash and electrical breakdown.

► Fire-retardant properties (NEMA XX or IEC equivalents)

► High mechanical strength

► Easy to machine and customize

These characteristics make phenolic boards an ideal alternative to more expensive thermoset composites in non-critical high-volume components.

3. Motor and Generator Insulation

Electric motors and generators require insulation that can handle mechanical vibration, heat, and electromagnetic stress. Phenolic paperboard is used to fabricate slot wedges, end laminations, and inter-phase insulation within the motor body.

► Maintains structure under mechanical stress

► Good electrical insulation in confined spaces

► Reduces short-circuit risk in windings

4. Power Distribution & Busbar Support Systems

In busbar assemblies and distribution cabinets, phenolic paperboard provides insulating supports, brackets, and barriers. The material is light, strong, and can be cut to shape, offering great versatility in panel design.

► Dielectric breakdown voltage > 10 kV/mm

► Easy integration with metal and plastic components

► Reduces risk of flashover and short-circuits

5. PCB Backing and Structural Laminates

Although fiberglass-based materials like FR4 dominate PCB manufacturing, phenolic paperboard is still widely used for low-frequency and consumer-grade electronics as the backing board for printed circuit boards.

► Cost-effective alternative

► Suitable for one-sided PCB layouts

► Flame-retardant and dimensionally stable

This use case remains significant in household electronics, toys, and small appliances.

Conclusion

Phenolic paper sheet continues to be a versatile, cost-effective, and reliable insulation solution in the electrical and power sectors. Its combination of electrical strength, thermal resistance, ease of processing, and long-term durability makes it indispensable for a variety of applications — from transformers and motors to switchgear and PCB backings.

Whether you are an OEM manufacturer or a distributor seeking dependable insulating materials, phenolic laminated paperboard remains a top choice for safe and efficient electrical design.