How G-10 Epoxy Fiberglass Laminated Sheets Enhance Transformer Safety and Performance

In the world of power distribution and electrical engineering, safety and efficiency are the cornerstones of any successful transformer design. One material that has steadily gained prominence for delivering on both fronts is the G-10 epoxy fiberglass laminated sheet. Known for its outstanding dielectric strength, thermal stability, and mechanical integrity, G-10 plays a vital role in improving the operational reliability of modern transformers.

This article explores how G-10 laminated sheets contribute to transformer insulation systems, increase longevity, and reduce the risk of failure in high-voltage environments.

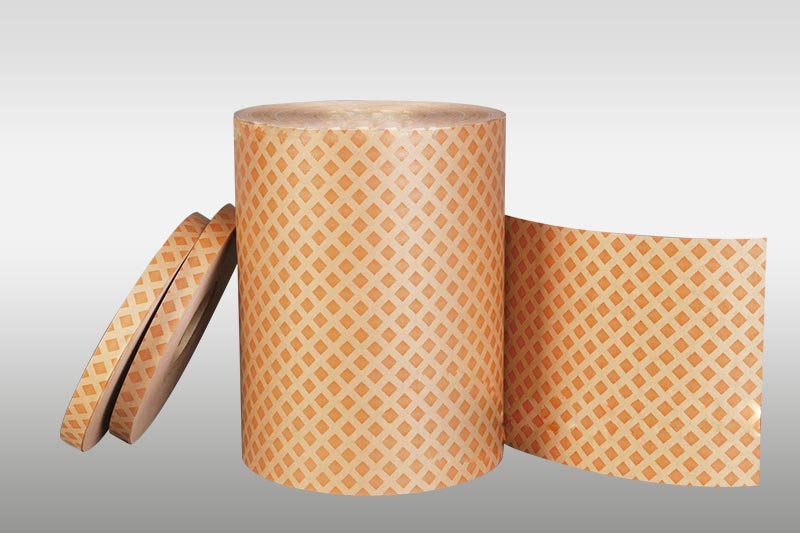

What Is G-10 Epoxy Fiberglass Laminated Sheet?

G-10 is a high-pressure, glass-reinforced epoxy laminate made from layers of woven fiberglass cloth impregnated with epoxy resin, compressed under heat and pressure. This structure results in a material that is both electrically insulating and mechanically robust, making it ideal for electrical and industrial insulation components.

High Dielectric Strength for Better Insulation

One of the biggest challenges in transformer operation is managing insulation between conductors. G-10 offers excellent dielectric strength, typically over 19 kV/mm, making it highly effective at withstanding high voltages without breaking down. When used in spacers, insulating barriers, or support frames, G-10 helps reduce the risk of arc faults and internal short circuits—leading causes of transformer failure.

Thermal Stability Improves Operational Safety

Transformers generate significant heat, especially during heavy load cycles. Materials used in transformer insulation must withstand elevated temperatures without deforming or losing strength. G-10 performs exceptionally in this area, with heat resistance up to 130°C depending on formulation. Its low thermal expansion coefficient ensures dimensional stability, which is critical for maintaining precise tolerances inside the transformer core.

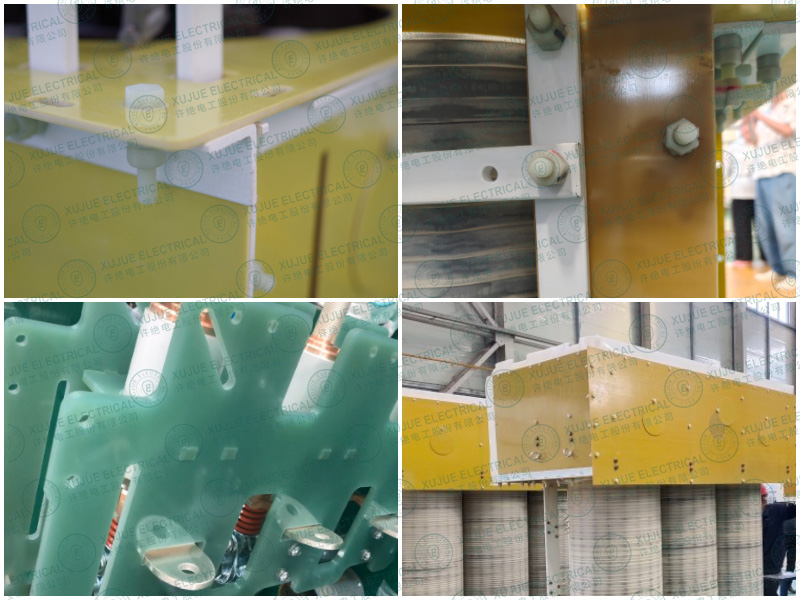

Mechanical Strength for Structural Reliability

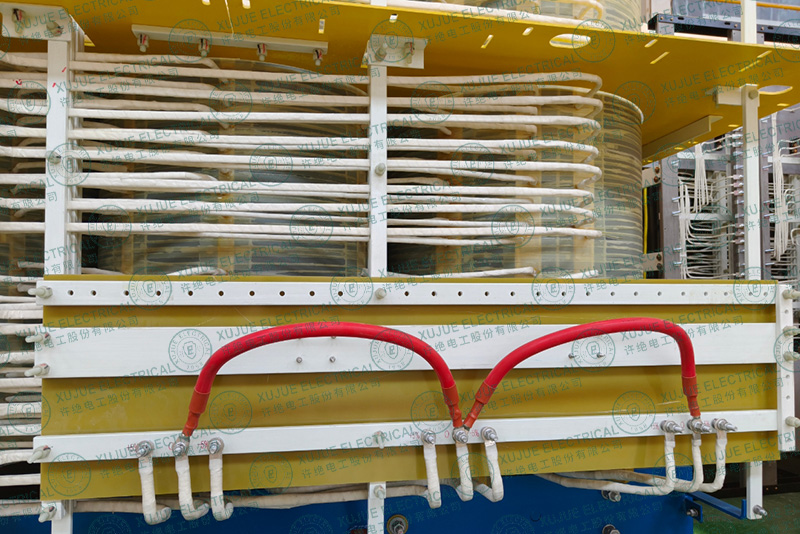

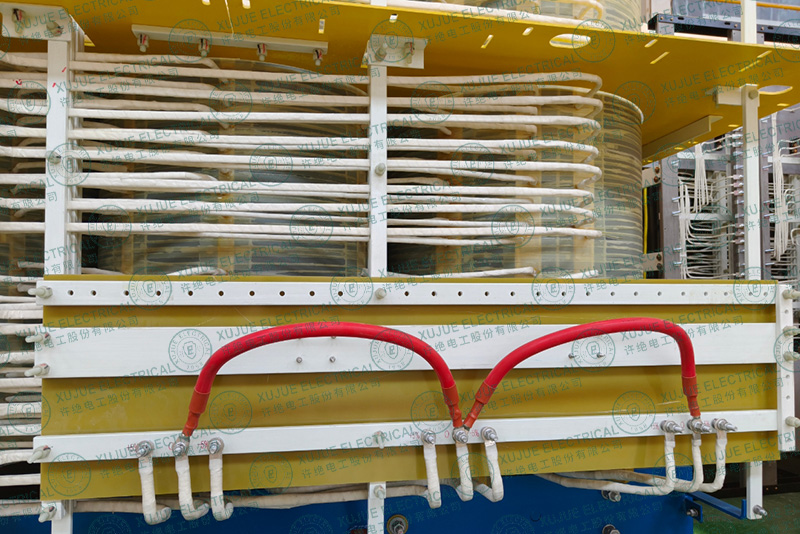

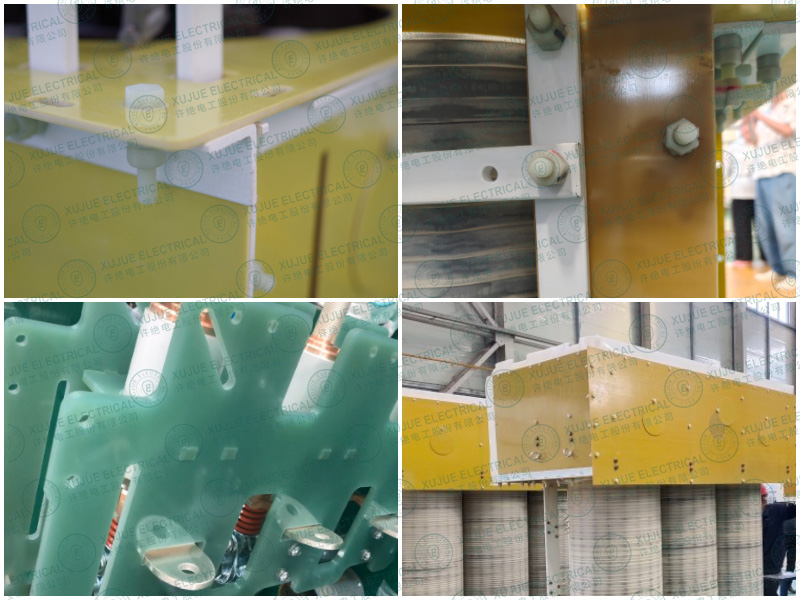

Beyond insulation, G-10 is also utilized in mechanical support structures within the transformer due to its high flexural strength and impact resistance. It resists deformation under stress and maintains its shape over time. This mechanical durability makes it suitable for bracing components, coil supports, and terminal boards where physical integrity is as crucial as electrical insulation.

Moisture Resistance Reduces Aging and Downtime

Transformers often operate in humid or oil-filled environments. G-10’s low water absorption and excellent resistance to oil and chemicals ensure it maintains its insulating properties even under harsh conditions. This translates to lower maintenance frequency, longer service intervals, and improved uptime.

G-10 vs. Other Insulation Materials

While other materials like 3240 or FR4 are also common in electrical insulation, G-10 surpasses them in mechanical toughness and thermal endurance. For high-performance transformers, G-10’s characteristics offer a superior balance of electrical, thermal, and structural protection—making it a preferred material for mission-critical applications.

Applications of G-10 in Transformers

G-10 is widely used in:

1. Insulation spacers and barriers

2. Coil and core structural support

3. Terminal boards

4. Mounting brackets

5. Control panel insulation

Its versatile application across low- to medium-voltage transformers underscores its value in both utility and industrial power systems.

Conclusion: A Smarter Choice for Modern Transformers

As demand for high-efficiency, safe, and long-lasting transformers increases globally, selecting the right insulation material becomes critical. G-10 epoxy fiberglass laminated sheets provide the essential balance of electrical performance, mechanical resilience, and thermal resistance needed in today’s transformer designs.

Whether you're a manufacturer, engineer, or procurement specialist, incorporating G-10 into your transformer system could be a strategic step toward reliability, performance, and cost efficiency.