Best Epoxy Laminates for Your Project: FR4, G10, G11, or 3240?

In the world of electrical insulation and mechanical support, epoxy laminated sheets are essential materials. Among the most popular are FR4, G10, G11, and 3240. Each has unique characteristics, and choosing the right one for your project can significantly impact performance, durability, and cost-efficiency.

So, how do these materials compare—and which one is the best fit for your application?

FR4: The Industry Standard for PCB and Electrical Insulation

FR4 is perhaps the most recognized name in epoxy laminates. Made of woven glass fabric and epoxy resin, it is known for:

1. Excellent electrical insulation

2. Flame retardancy (UL94 V-0 rating)

3. Strong mechanical properties

4. High moisture resistance

Applications: FR4 is ideal for printed circuit boards (PCBs), electrical insulation, switchgear back panels, and relays.

Best for: Electronics and general electrical applications needing flame resistance and consistent strength.

G10: The Tough, Non-Flame-Retardant Alternative

G10 is nearly identical to FR4 but lacks the flame retardant additives. It is widely used where flame resistance is not critical but strength and insulation are still required.

1. High mechanical strength

2. Great dimensional stability

3. Excellent bonding strength and moisture resistance

Applications: Aerospace parts, mechanical spacers, insulator blocks.

Best for: Mechanical applications with less focus on fire safety.

G11: Enhanced High-Temperature Performance

G11 is a high-grade version of G10, designed for thermal endurance. It maintains mechanical and electrical properties at elevated temperatures.

1. Continuous operation up to 155°C

2. Superior arc and tracking resistance

3. Maintains strength in moist and humid conditions

Applications: High-temperature electrical systems, turbine generators, military-grade insulators.

Best for: Environments with continuous high heat and critical electrical demands.

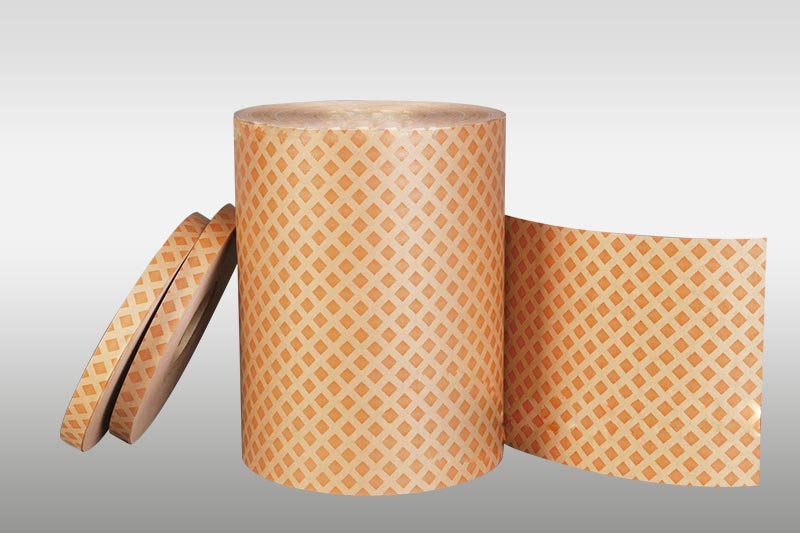

3240: The Economic Phenolic Epoxy Sheet

3240 epoxy sheet, typically yellow or light green, is made from epoxy resin and glass cloth. It offers:

1. Strong electrical insulation

2. High mechanical strength

3. Moderate thermal performance (130°C)

4. Lower cost than FR4 or G11

Applications: Transformers, control cabinets, electric tools, machinery insulation components.

Best for: Cost-effective insulation solutions in industrial and transformer applications.

Which Epoxy Laminate Should You Choose?

|

Material |

Flame Retardant |

Max Temp |

Moisture Resistance |

Price |

Best Use |

|

FR4 |

✅ UL94 V-0 |

~130°C |

✅✅✅ |

$$ |

PCB, electrical panels |

|

G10 |

❌ |

~130°C |

✅✅ |

$ |

Mechanical insulators |

|

G11 |

✅ |

~155°C |

✅✅✅ |

$$$ |

High-temp systems |

|

3240 |

❌ |

~130°C |

✅ |

$ |

Cost-efficient industrial insulation |

Final Thoughts

Choosing the right epoxy laminate depends on your application environment, temperature requirements, cost limits, and performance expectations.

If you’re looking for affordable insulation, 3240 is the go-to. For PCBs, FR4 is the industry leader. G10 offers a strong, reliable alternative for mechanical parts, while G11 stands out for thermal endurance and high-voltage insulation.

At XuJue, we offer all four materials—custom cut and processed to your specifications. Need help choosing? Our expert team is here to guide you