Unlocking the Potential of 3240 Epoxy Glass Cloth Laminated Sheet: Features and Industrial Advantages

Introduction

In the field of electrical insulation and mechanical support materials, 3240 epoxy sheets stand out as a reliable and high-performance option. Known for their excellent electrical insulation, thermal resistance, and mechanical strength, 3240 sheets are widely used in industrial sectors such as electrical engineering, motor manufacturing, and transformer systems. This article explores the key properties of 3240 sheets and how these features translate into tangible benefits in real-world industrial applications.

1. What Is 3240 Epoxy Laminate?

The 3240 sheet is a thermosetting laminate, made by impregnating alkali-free glass cloth with epoxy resin, then hot-pressing it under high temperature and pressure. It conforms to GB/T 1303.1-2009 and IEC 60893 international standards, and is similar in performance to NEMA G10.

Key Composition:

► Epoxy resin (binder)

► Woven glass cloth (reinforcement)

►Curing agents and flame retardants (optional)

3240 offers a balanced combination of electrical, thermal, and mechanical properties:

|

Feature |

Performance Advantage |

|

High Dielectric Strength |

Ensures insulation safety up to 20 kV/mm |

|

Heat Resistance |

Operates stably at temperatures to 130°C (Class B) |

|

High Mechanical Strength |

Supports heavy loads and structural rigidity |

|

Moisture Resistance |

Maintains integrity in humid environments |

|

Machinability |

Suitable for CNC, drilling, and punching without cracking |

These properties make 3240 an ideal electrical insulation material for demanding applications.

3. Industrial Applications of 3240 Laminate

Due to its durability and insulating capabilities, 3240 finds applications in multiple industries:

► Transformers: Used as structural supports, insulating gaskets, coil frames

► Motors: For slot wedges, end caps, and insulation plates

► Switchgear & Distribution Cabinets: As partition boards, arc barriers, or mounting plates

► Mechanical Components: For precision gaskets and machined insulation parts

► Electronics: In relay bases and electrical control panels

Fun Fact: Many global motor OEMs prefer 3240 due to its combination of affordability and reliability.

4. Advantages in Manufacturing and Cost Control

Compared with higher-spec materials like FR4 or G11, 3240 offers cost-efficiency while maintaining sufficient performance in most medium-voltage or general-purpose applications.

Manufacturing Benefits:

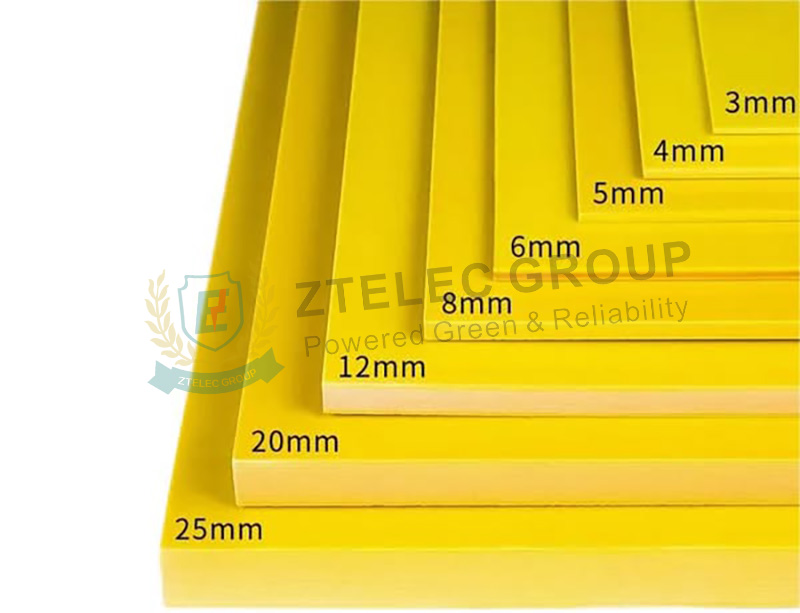

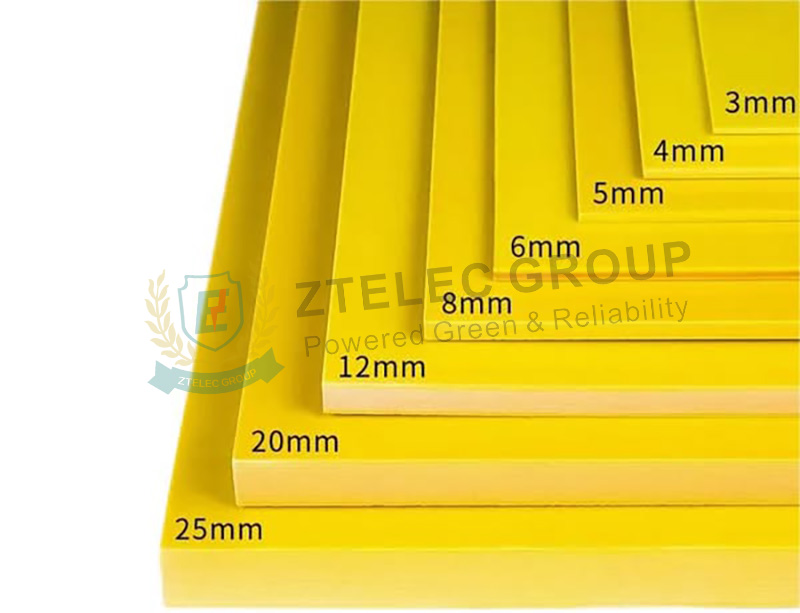

► Available in a variety of thicknesses (0.5mm – 50mm)

►Consistent quality and dimensional stability

►Compatible with automated machining processes

This allows manufacturers to reduce costs on insulation parts without compromising product safety or life span.

5. Storage and Handling Tips for Longevity

To ensure long-term performance of 3240 laminates:

► Store in dry, ventilated areas below 25°C

►Avoid exposure to UV rays or direct sunlight

►Use pallets or racks to avoid warping

►Follow first-in, first-out (FIFO) inventory practices

These steps prevent moisture absorption and preserve electrical properties over time.

Conclusion: Why Choose 3240?

The 3240 epoxy glass cloth laminated sheet is a proven, versatile, and cost-effective insulation material for various industrial uses. Whether you’re designing motors, transformers, or electrical control systems, 3240 offers the performance, durability, and manufacturability needed for modern applications.

Choosing 3240 means investing in a material that provides reliable insulation, structural support, and value for money—a smart choice for OEMs and electrical component manufacturers worldwide.