How to Store and Handle FR4 Epoxy Sheets for Long-Term Use Without Performance Loss

Introduction:

FR4 epoxy sheets are one of the most commonly used materials in the electrical insulation and PCB manufacturing industries. Known for their excellent mechanical strength, flame resistance, and electrical insulation, FR4 laminates are essential in transformers, circuit boards, motors, and control panels. However, incorrect storage and handling can compromise their performance over time. This article outlines best practices for storing and handling FR4 sheets to ensure durability, stability, and long-term usability—especially in environments with moisture, heat, or UV exposure.

1. Why Long-Term Storage of FR4 Sheets Matters

Although FR4 is highly durable, it is also hygroscopic—meaning it naturally absorbs moisture from the air. When improperly stored, FR4 laminates can suffer from:

1. Reduced dielectric strength

2. Delamination or surface blistering

3. Warping and loss of dimensional stability

4. Mechanical degradation in high-stress environments

To prevent these issues, proper long-term storage methods must be implemented from the start—especially for stock used in high-voltage or precision electrical applications.

2. Best Environmental Conditions for Storing FR4 Epoxy Sheets

Maintaining a controlled storage environment is crucial. Here’s what you should aim for:

|

Storage Parameter |

Recommended Range |

|

Temperature |

15°C – 25°C (59°F – 77°F) |

|

Relative Humidity |

≤ 60% RH |

|

Sunlight/UV Exposure |

None (store in shaded area) |

|

Air Circulation |

Moderate ventilation |

♦ Use dehumidifiers in coastal or humid regions.

♦ Avoid direct sunlight or warehouse skylights.

♦ Maintain indoor air stability to prevent thermal expansion.

Tip: Installing a temperature and humidity data logger helps track environmental consistency.

3. Proper Handling and Packaging Guidelines

To avoid damage during transit, storage, and processing, follow these essential steps:

1. Store vertically using A-frame racks to prevent bowing.

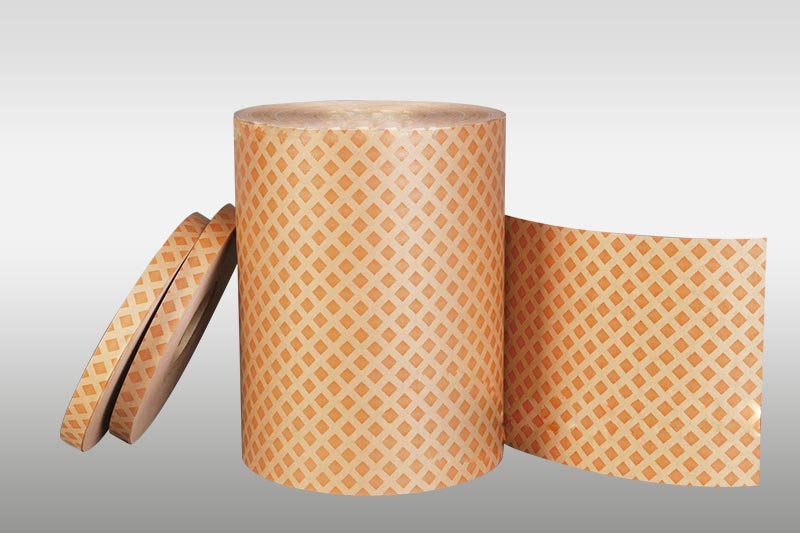

2. Interleave sheets with kraft paper or PE film to avoid surface scratches.

3. Handle with clean cotton or anti-static gloves to prevent contamination from oils or moisture.

4. For export, vacuum-pack with desiccant packets, and seal in moisture-barrier bags.

For large FR4 sheets (1020mm x 1220mm or bigger), avoid stacking more than 30 sheets without separators.

4. Shelf Life Monitoring and Inventory Control

While FR4 epoxy boards don’t have a fixed expiration date, performance may degrade after 12 to 24 months if poorly stored.

What to do:

1. Conduct quarterly visual checks for yellowing, cracks, or warping.

2. Test dielectric strength and water absorption for critical applications.

3. Practice FIFO (First-In, First-Out) inventory rotation with labeling including batch number, production date, and storage entry time.

5. Shipping Best Practices for FR4 Laminates

Shipping is often overlooked but plays a major role in maintaining product integrity:

1. Use pallets with corner protectors to prevent impact damage.

2. Add “Keep Dry” and “Do Not Stack” markings.

3. Use climate-controlled logistics for overseas shipments or temperature-sensitive models like FR4 with high Tg.

Also, communicate clear handling guidelines to all parties in the supply chain.

Conclusion: Preserve Quality, Maximize Value

FR4 epoxy laminates are a premium material. But without proper storage, handling, and environmental control, their advantages—like insulation strength and mechanical stability—can be lost before they’re even used.

Investing in proper storage racks, climate control, and packaging will help ensure your FR4 stock is always production-ready, compliant with industry standards, and capable of delivering maximum cost-efficiency and performance.