The Ultimate Guide - Crepe Paper tube in Oil-Immersed Transformers

In the field of power distribution, oil-immersed transformers are a cornerstone of safe and efficient energy transfer. While major components like cores and windings get much of the attention, the role of insulation materials is just as crucial. Among them, crepe paper and crepe paper tubes have emerged as vital insulation solutions, offering exceptional dielectric strength, flexibility, and oil absorption. In this guide, we explore their properties, applications, and benefits in transformer design—particularly for long-term performance and cost-effective operation.

1. What Is Crepe Paper for Transformers?

Crepe paper is a specialized electrical-grade insulating paper with a wrinkled or “creped” surface, giving it greater stretchability and surface area than flat kraft or presspaper. It is usually made from 100% pure cellulose and processed without conductive contaminants, making it ideal for high-voltage insulation.

Key Properties:

1.Excellent elongation rate (up to 250%)

2. High dielectric strength

3. Enhanced oil absorption and impregnation capability

4. Conformability to tight winding geometries

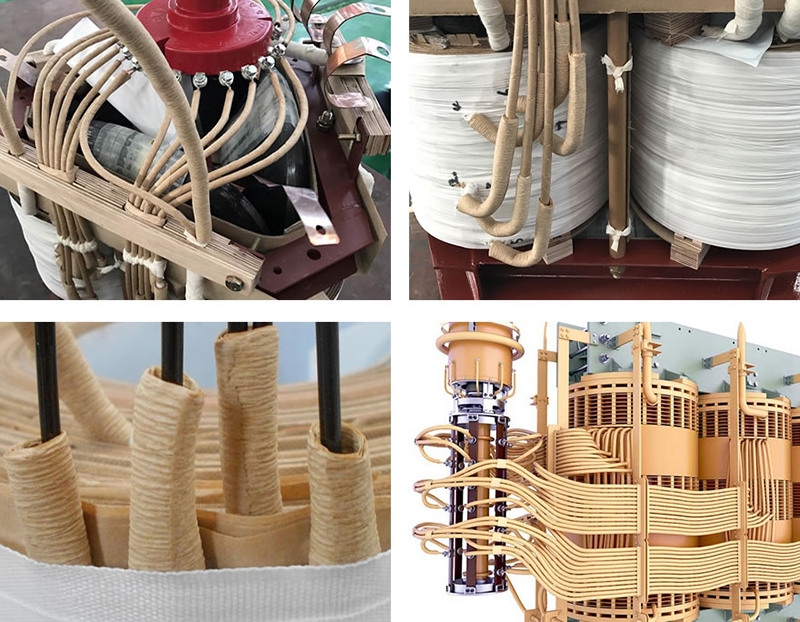

2. Why Crepe Paper Matters in Oil-Immersed Transformers

Oil-immersed transformers require insulation that can perform reliably under thermal and electrical stress. Crepe paper's mechanical flexibility helps reduce stress concentrations during transformer operation and thermal cycling, especially where conductors bend or vibrate.

Main Benefits:

1. Prevents partial discharge and electrical breakdown

2. Fills voids and air gaps in complex winding structures

3. Works in synergy with transformer oil for enhanced insulation

4. Ideal for conductor wrapping and spacer insulation

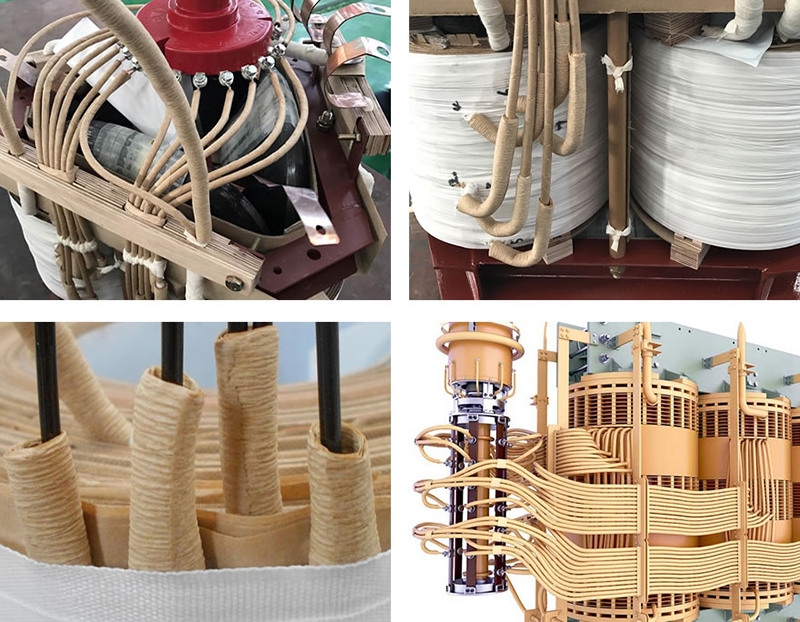

3. Applications of Crepe Paper Tubes

Crepe paper tubes, formed by winding layers of creped paper into cylindrical shapes, are used for insulation around leads, connectors, and inner transformer structures. These tubes provide dimensional stability, dielectric isolation, and mechanical protection.

Common Applications:

1. Terminal lead insulation

2. Layer separators in windings

3. Structural support for transformer internals

4. Oil channels and spacers

Crepe paper tubes can also be customized in diameter, wall thickness, and length to suit various transformer designs.

4. Compatibility with Transformer Oil

One of the unique advantages of crepe paper and crepe tubes is their high oil absorption rate. This feature allows for fast and thorough impregnation with mineral or natural ester transformer oils, enhancing dielectric performance and long-term aging resistance.

They also have a low shrinkage rate, ensuring dimensional stability even after prolonged exposure to heat and oil.

5. Performance Standards and Compliance

1. High-quality crepe paper products used in transformer manufacturing generally meet the following standards:

2. IEC 60554-3 for electrical insulating paper

3. Thermal Class A (105°C) or higher depending on grade

By choosing certified products, manufacturers ensure safety, consistency, and long service life in demanding applications.

6. Why Choose ZTelec for Transformer Crepe Paper Solutions?

ZTelec specializes in manufacturing high-performance crepe paper and crepe tubes for global transformer producers. we offer customized solutions tailored to your voltage, size, and thermal class requirements. Our materials are trusted in oil-filled transformers in over 50 countries.

Conclusion

In summary, crepe paper and crepe paper tubes are not just filler materials—they are key components in ensuring the electrical integrity and operational reliability of oil-immersed transformers. Their ability to conform, insulate, and integrate with transformer oil makes them indispensable in both small and large-scale transformer designs. Choosing the right insulation partner is essential for performance and peace of mind.