SMC vs FRP: Which Composite Material Is More Cost-Efficient?

Introduction

In industries such as electrical, automotive, and construction, composite materials like SMC (Sheet Molding Compound) and FRP (Fiber Reinforced Plastic) have gained widespread usage for their strength, durability, and lightweight properties. However, when choosing between SMC and FRP, cost efficiency often becomes the decisive factor. This article explores the cost-performance ratio of both materials, highlighting which one delivers better value for money based on application, material properties, processing, and long-term usage.

1. Understanding the Basics: What Are SMC and FRP?

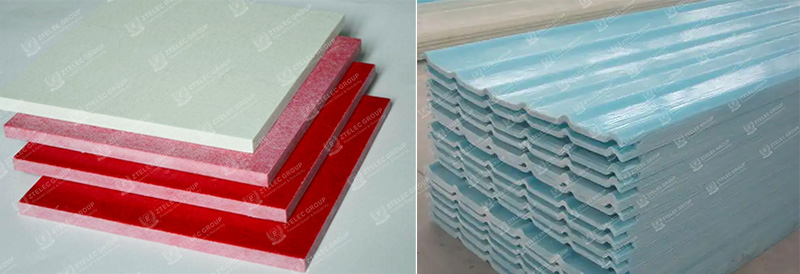

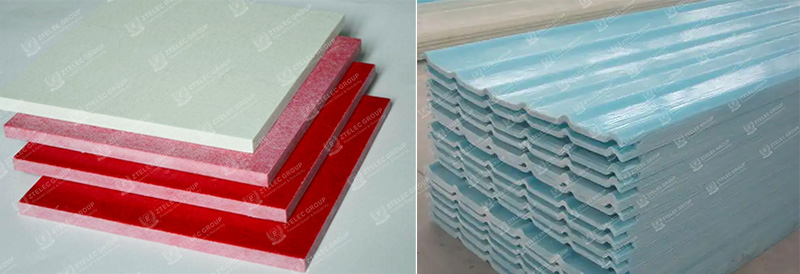

SMC is a compression-molded composite made from a thermosetting resin, typically polyester, reinforced with chopped glass fibers. It is often used in applications requiring precise molding and high strength.

FRP, on the other hand, is a broad category of composites that typically use glass, carbon, or aramid fibers with a resin matrix. It includes materials like GFRP (Glass Fiber Reinforced Plastic), and is well known for its flexibility in manufacturing processes such as pultrusion, hand lay-up, and filament winding.

2. Material Costs and Availability

In general, SMC tends to be more cost-effective in large-scale production due to its high-volume molding capabilities and material uniformity. The raw materials for SMC are widely available and relatively inexpensive compared to advanced FRP systems, particularly those using high-performance fibers or resins.

FRP can become more costly depending on the fiber type and resin used. For example, carbon fiber-reinforced FRP is significantly more expensive than SMC due to its superior strength-to-weight ratio.

3. Manufacturing and Processing Efficiency

SMC sheets are designed for automated compression molding, which ensures lower cycle times, consistent part quality, and reduced labor costs. This makes SMC a better option for mass production with tight tolerances and fast turnaround requirements.

FRP, especially when produced via manual processes like hand lay-up, may involve longer processing times, increased labor, and greater potential for variability. However, FRP offers more design flexibility and is better suited for custom or low-volume applications.

4. Mechanical and Thermal Performance vs. Cost

While FRP generally offers superior mechanical strength and corrosion resistance, SMC provides an excellent cost-performance balance in applications where ultra-high strength is not a necessity. SMC also boasts good flame retardancy, dielectric properties, and dimensional stability, especially in electrical applications.

For applications like transformer parts, switchgear housings, or structural supports, SMC delivers competitive mechanical and thermal performance at a lower price point compared to high-end FRP.

5. Lifecycle and Maintenance Costs

Both SMC and FRP offer low maintenance and excellent resistance to environmental degradation. However, SMC’s closed mold process ensures better surface finish and lower porosity, reducing post-processing costs and improving product lifespan in harsh conditions.

In contrast, FRP structures may require surface treatment or coatings, especially when exposed to UV, chemicals, or moisture for extended periods.

Conclusion: Which One Saves More?

When evaluating cost-effectiveness, SMC sheets are often the more economical choice for standardized, high-volume production needs. They offer a great balance between cost, strength, and production efficiency.

FRP remains a valuable material when design flexibility and tailored performance are required — particularly for unique, complex, or low-run components.

Ultimately, the best material choice depends on your application’s scale, performance requirements, and budget constraints. Partnering with a knowledgeable insulation material supplier can help you determine the most suitable and cost-effective solution for your specific project.