Epoxy Sheets in Lithium Battery Applications: Advanced Protection and Performance

As the global demand for lithium batteries accelerates—driven by electric vehicles (EVs), energy storage systems, and portable electronics—the need for robust packaging and thermal-insulating materials has never been more critical. Among these materials, epoxy sheets (FR4, G10, 3240) are gaining prominence for their exceptional insulation, barrier protection, mechanical strength, and thermal stability. These properties make epoxy sheets an ideal solution for modern battery pack design and safety enhancement.

Why Use Epoxy Sheets in Lithium Battery Packs?

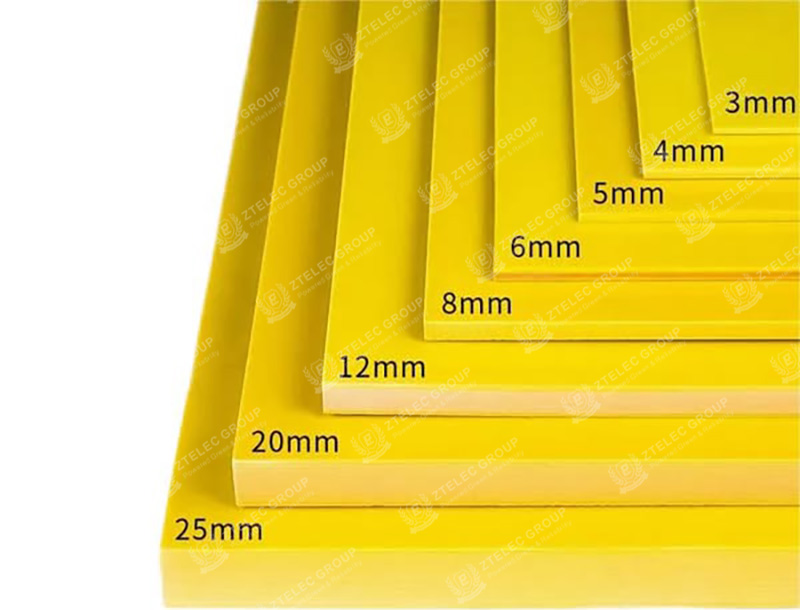

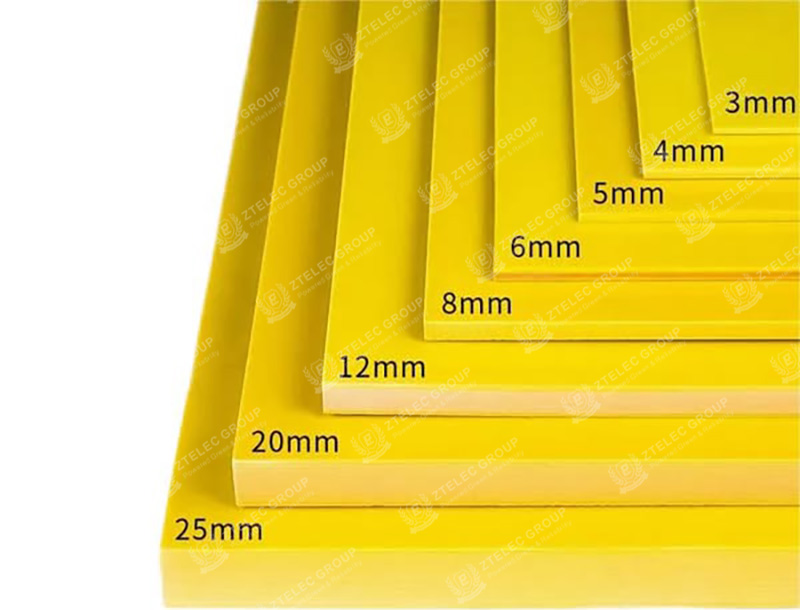

Epoxy sheets are thermoset composite materials made by impregnating glass fiber cloth with epoxy resin under heat and pressure. They offer the perfect balance of mechanical toughness and electrical insulation, making them highly suitable for demanding environments within lithium battery systems.

Here’s how epoxy sheets contribute to lithium battery safety and performance:

1. Electrical Insulation Between Cells

One of the core concerns in battery pack design is preventing short circuits. Epoxy sheets serve as insulation barriers between battery cells and between the cell module and the outer enclosure. Their high dielectric strength ensures safe operation, even under high voltage conditions, reducing the risk of internal arcing or thermal runaway.

2. Thermal Barrier and Fire Retardancy

Temperature regulation is essential in lithium battery systems to avoid overheating or fire hazards. Epoxy sheets, especially FR4 and G10, are valued for their thermal insulation properties and flame retardancy (UL94-V0 rated). These attributes help control heat propagation during overcharge, impact, or thermal failure, acting as a critical thermal barrier layer.

3. Structural Support and Dimensional Stability

Battery modules require rigid and lightweight materials for housing and structural support. Epoxy sheets maintain high dimensional stability under thermal and mechanical stress, ensuring that battery components remain intact and aligned even during transportation or mechanical shocks. This stability improves battery longevity and reliability.

4. Chemical Resistance in Harsh Environments

Epoxy sheets are resistant to moisture, oils, and most chemicals commonly found in industrial or automotive environments. This makes them ideal for battery packs used in EVs, power tools, or grid storage systems, where exposure to chemicals and environmental stress is frequent.

5. Cost-Effective Custom Machining

Epoxy sheets can be easily CNC machined, laser cut, or punched into various shapes like insulation pads, barriers, or battery slot supports. This versatility allows for customized battery pack designs without significant cost or production delays.

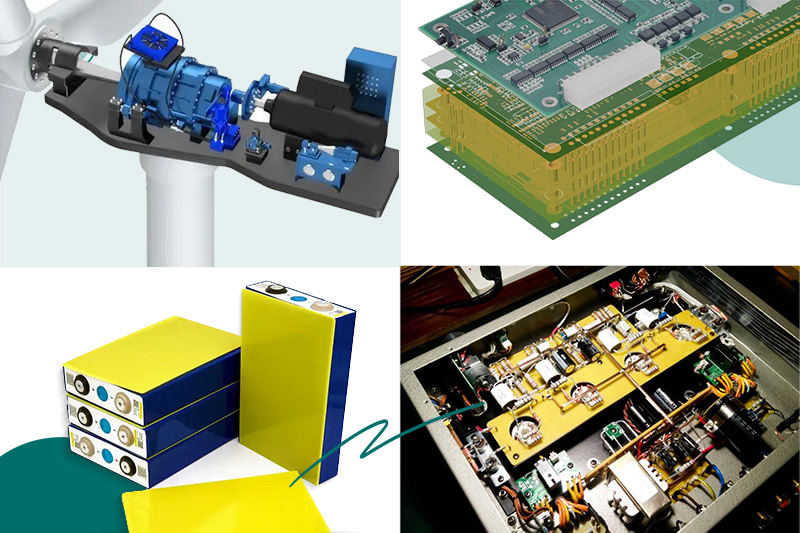

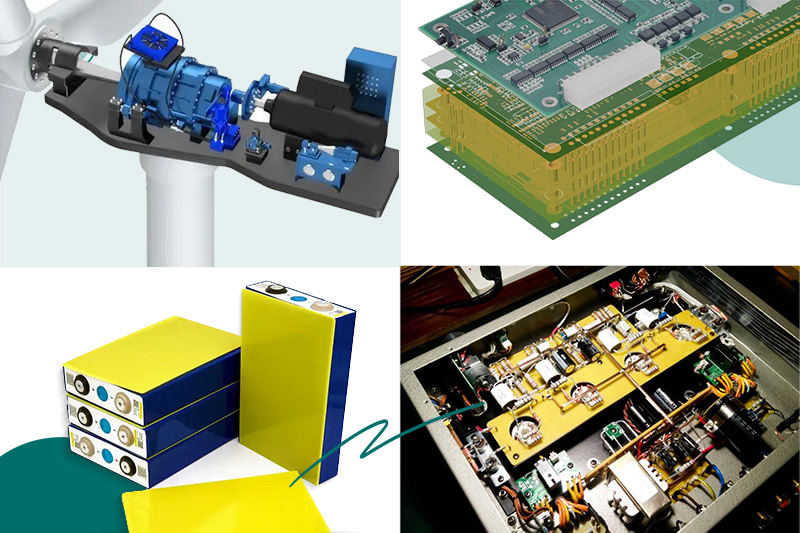

Typical Applications:

1. EV battery module insulation plates

2. Cell-to-cell insulation barriers

3. Battery end covers and enclosure liners

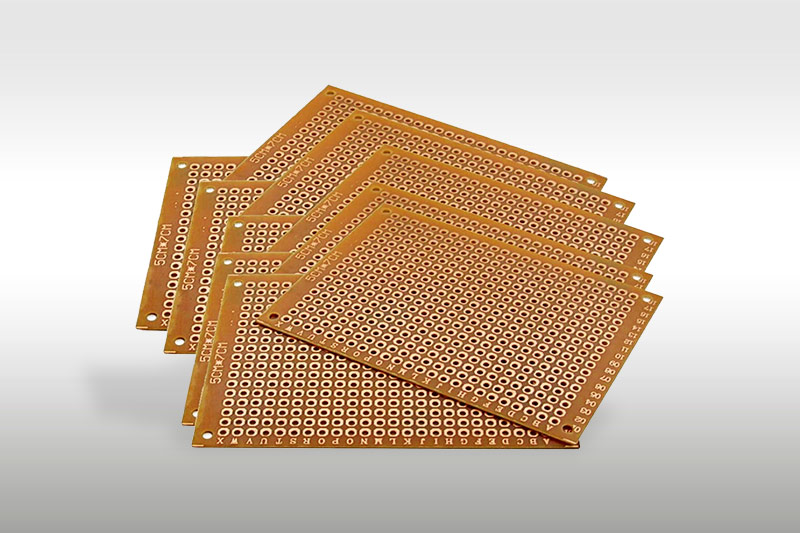

4. PCB insulation within battery BMS systems

5. Thermal shields and fire retardant layers

Conclusion

Epoxy sheets have become an essential material in the lithium battery industry, combining electrical insulation, thermal resistance, and mechanical durability. Whether you are designing energy-dense EV batteries or compact battery modules for portable devices, epoxy laminates ensure a safer, longer-lasting, and more efficient energy storage solution.

For high-quality G10, FR4, or 3240 epoxy sheets tailored to your battery application needs, contact us . We offer precision cutting and customization services, fast delivery, and professional technical support.