Unveiling G10 Glass Fiber Laminate: Multilayer Composite Structure and Its Performance Advantages

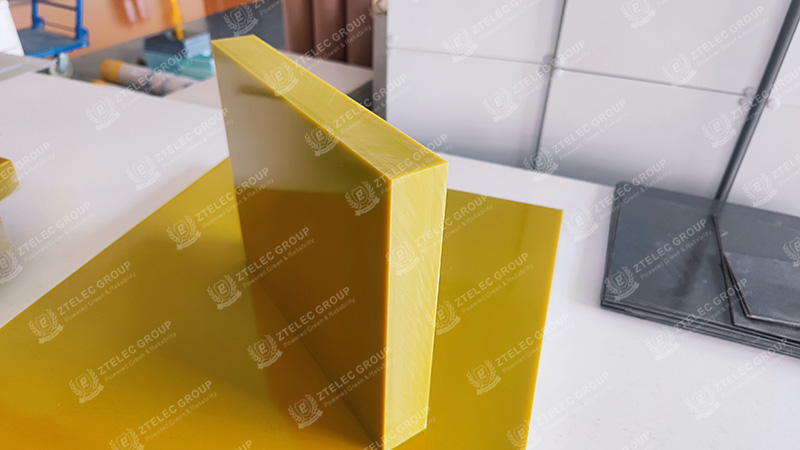

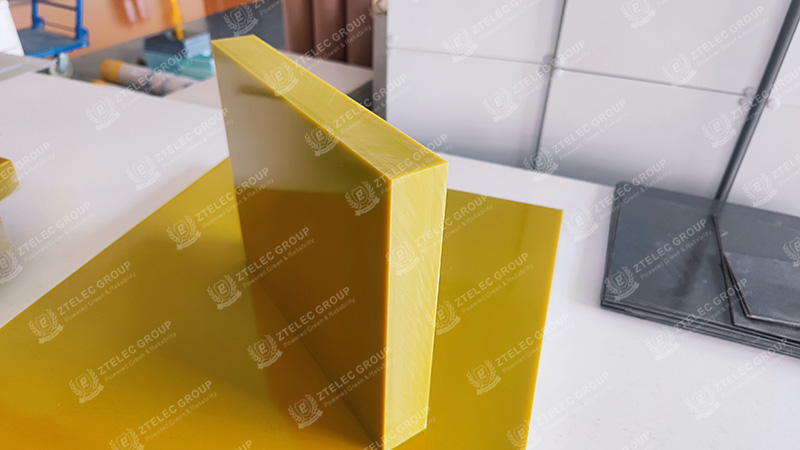

In the world of industrial materials, G10 glass fiber laminate stands out as a versatile, high-performance composite. Built on a foundation of woven fiberglass cloth and epoxy resin, G10 is engineered through high-temperature, high-pressure lamination, resulting in a material that delivers exceptional electrical insulation, mechanical strength, and dimensional stability.

So, what makes G10 such a reliable choice for critical applications? The answer lies in its multilayer composite structure — and the unique advantages it brings to diverse industries.

The Multilayer Construction of G10

G10 sheets are manufactured through a laminated structure made up of multiple layers of fiberglass cloth, each impregnated with thermosetting epoxy resin. These layers are stacked, aligned, and cured under heat and pressure to create a homogenous, compact material.

This fiber-reinforced structure ensures:

1. Consistent dielectric strength throughout the sheet

2. Uniform mechanical performance in all directions (isotropic behavior)

3. Superior thermal resistance and moisture stability

4. Minimal warping or delamination under high load or temperature conditions

Key Performance Advantages of G10

1.Electrical Insulation Reliability

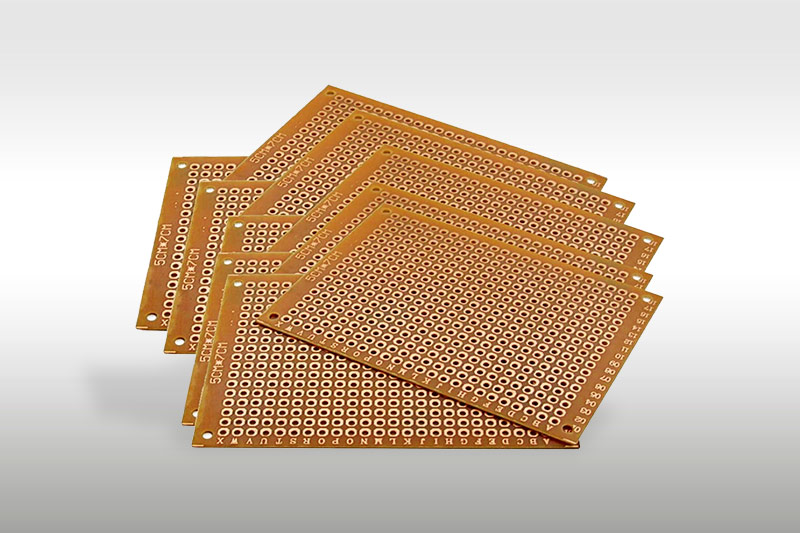

With a dielectric strength often exceeding 500 V/mil, G10 excels in electrical insulation even in humid or high-voltage environments. It’s a preferred material for circuit boards, switchgear insulation, and electrical enclosures.

2.Outstanding Mechanical Strength

Thanks to the fiberglass matrix, G10 exhibits high tensile and flexural strength, making it resistant to mechanical stress, wear, and impact — critical for structural components and tooling.

3.Moisture Resistance

The epoxy matrix creates a non-porous surface, preventing water absorption and maintaining performance in damp or outdoor conditions, which is essential in marine, aerospace, and outdoor electronics applications.

4.Machinability

Despite its hardness, G10 is relatively easy to cut, mill, and drill with carbide tools, making it suitable for custom machining into gaskets, insulators, bushings, and high-precision parts.

5.Thermal and Flame Resistance

G10 retains stability up to 130–150°C (depending on resin system) and is self-extinguishing, meeting flame-retardant standards such as UL 94 HB. For higher requirements, users may opt for G11 or FR4.

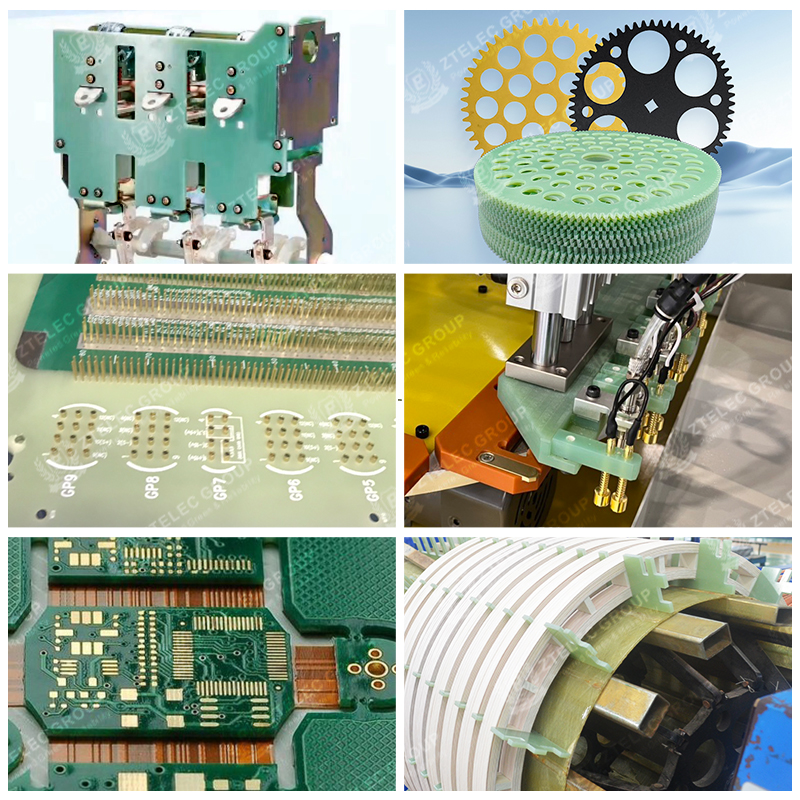

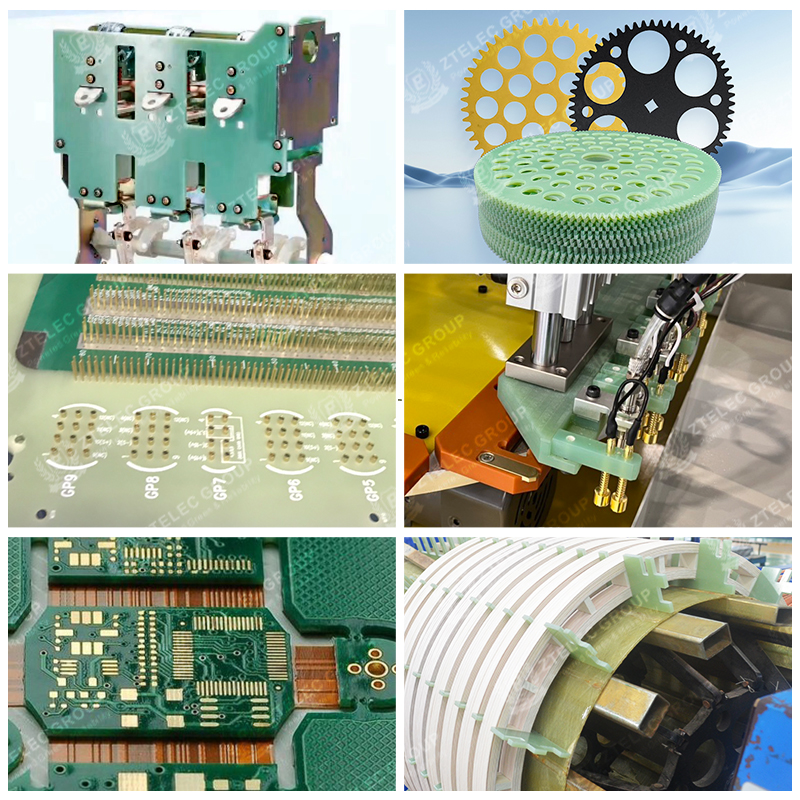

Common Applications of G10 Laminate

1. PCB substrates and electrical insulation boards

2. Battery pack separators and motor slot wedges

3. Structural support in drones, RC hobby gear, and tools

4. Knife handles and composite grips (due to aesthetics and grip texture)

5. Aerospace and marine paneling

6. Mechanical jigs and fixtures for industrial use

Why G10 for Your Project?

Choosing G10 means selecting a material that offers a balance of strength, stability, and reliability. It performs under pressure, resists moisture, and maintains integrity over time — all while being cost-effective and customizable.

As global industries push for higher-performance materials in smaller, more efficient systems, G10 remains a trusted standard across electronics, energy, transportation, and precision engineering.

Looking for high-quality G10 sheets, rods, or custom-machined parts?

We offer full customization, fast delivery, and expert support for your insulation and structural needs.

Contact us today to learn more or request a quote.