Mastering Phenolic Paper Tubes: Performance, Uses, and Industry Standards

Introduction

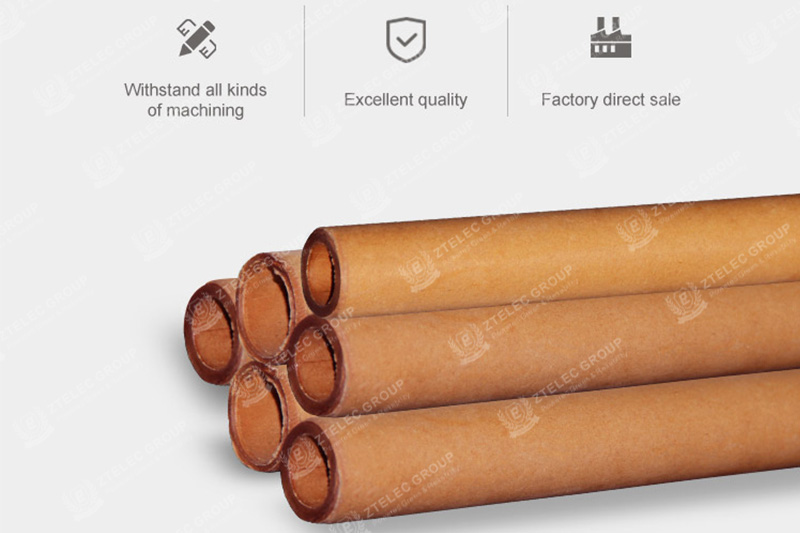

Phenolic paper tubes are a critical component in the world of electrical insulation and mechanical support, widely used across industries such as electrical manufacturing, electronics, aerospace, and automotive. Made from high-grade insulating kraft paper impregnated with phenolic resin and cured under heat and pressure, these tubes deliver outstanding dielectric strength and mechanical integrity.

Phenolic paper tubes, also known as bakelite paper tubes or paper-based phenolic tubes, are composite cylindrical materials formed from layers of insulating paper bonded with phenolic resin. Once cured, the result is a rigid, heat-resistant, and electrically insulating tube.

These tubes typically conform to international standards such as IEC, NEMA (e.g., NEMA HP-5), or GB standards, ensuring their suitability for various high-performance environments.

Key Applications of Phenolic Paper Tubes

1. Transformer Components

Used for insulation cylinders, oil ducts, and structural spacers inside oil-immersed transformers due to their high dielectric strength and oil resistance.

2. Motor Insulation

Employed in electric motors as slot liners or phase separators, providing thermal insulation and maintaining component integrity under rotational forces.

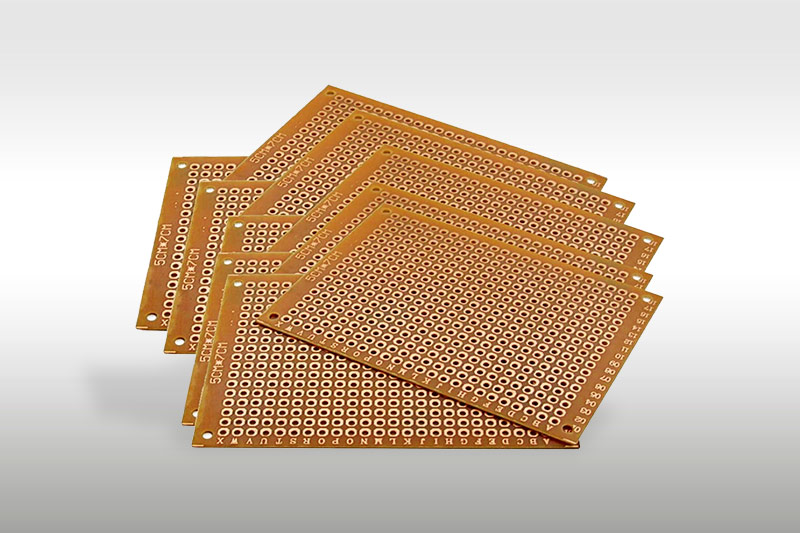

3. Electronics and PCB Manufacturing

Used as structural holders or supports in high-voltage electronic assemblies due to their dimensional stability and flame resistance.

4. Aerospace and Automotive Industries

Preferred for lightweight mechanical parts that also require electrical insulation.

Technical Advantages

► Excellent Electrical Insulation:

Dielectric strength typically exceeds 8–12 kV/mm, making it ideal for high-voltage environments.

► Thermal Resistance:

Heat resistance up to Class E .

► Mechanical Strength:

Resistant to compression and impact, ideal for load-bearing applications.

► Machinability:

Easy to drill, cut, or lathe without cracking or delamination, enabling precise custom parts.

Why Choose Phenolic Paper Tubes from ZTelec?

ZTelec’s phenolic paper tubes are manufactured under strict quality controls, offering consistent resin distribution, tight tolerances, and customizable lengths and diameters. With over 20 years of experience in insulation materials, we deliver both standard and tailored solutions to meet your specific technical and regulatory requirements.

Conclusion

Whether you're designing a high-efficiency transformer or need robust insulation components for a motor or circuit assembly, phenolic paper tubes offer the ideal balance of electrical insulation, mechanical durability, and thermal resistance. Contact ZTelec today to learn more about our complete range of insulation tubes and how they can be integrated into your next project.