Why Insulation Paper Is Essential for Electric Motors: Principles, Applications, and Long-Term Benefits

In electric motors, reliable insulation is not just a design choice—it is a necessity. One of the most critical components for ensuring this insulation is insulation paper. Made from materials such as cellulose, aramid fiber, or composite layers, insulation paper plays a vital role in protecting motor windings, preventing short circuits, and ensuring long-term operational stability.

The Critical Role of Insulation Paper in Electric Motors

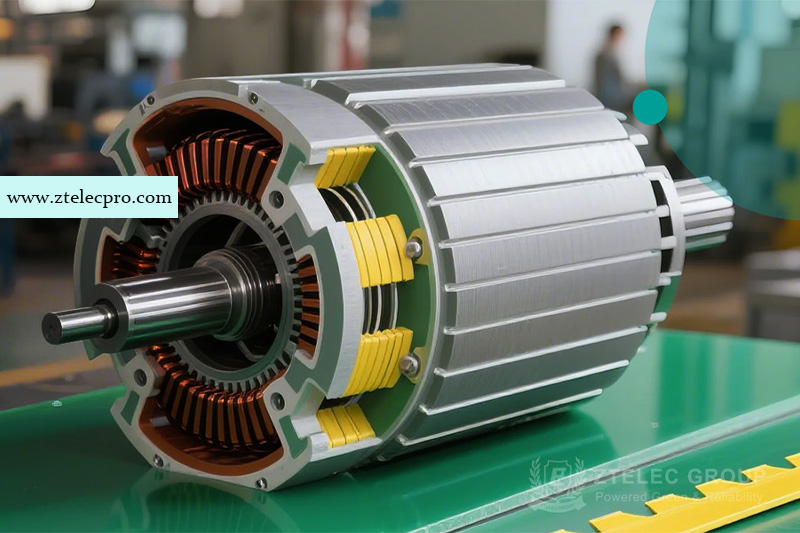

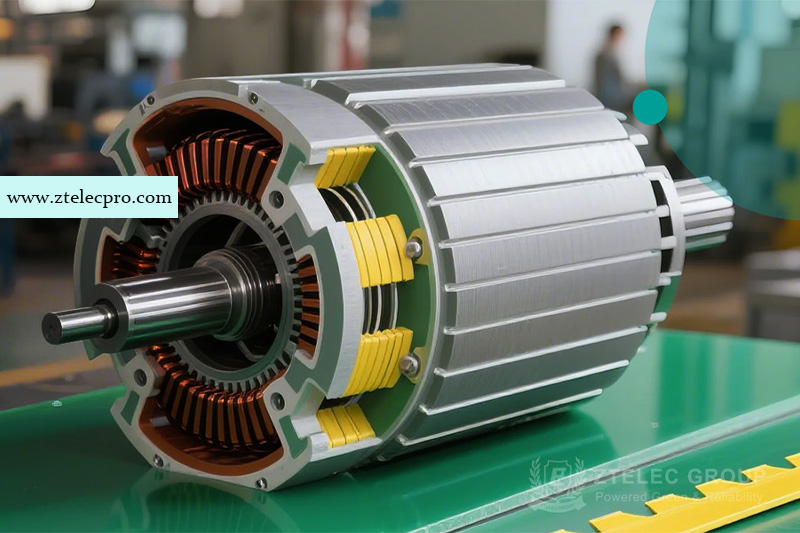

Electric motors operate by converting electrical energy into mechanical energy through the interaction of magnetic fields generated by coils. These coils are wound with conductive copper or aluminum wires, and if these wires are left uninsulated or poorly insulated, the risk of phase-to-phase short circuits, ground faults, or dielectric breakdown dramatically increases.

Insulation paper acts as a dielectric barrier—it separates conducting components electrically while allowing the safe transfer of energy. It is placed between windings, between the core and windings, and around terminals, acting as a protective layer to isolate electrical current.

Key Benefits of Using Insulation Paper in Motors

1. Electrical Protection

High-dielectric strength insulation paper prevents unwanted electrical discharge. This is especially important in high-voltage or high-speed motors where even a small failure in insulation can result in costly damage.

2. Thermal Stability

Modern insulation papers are engineered to withstand high temperatures—often up to 130°C (Class B), 155°C (Class F), or even 180°C (Class H). This makes them ideal for use in industrial-grade motors exposed to continuous thermal stress.

3. Mechanical Durability

Insulation papers offer excellent mechanical strength and dimensional stability. They can resist vibration, abrasion, and deformation, ensuring that the insulation remains intact even under harsh operating conditions.

4. Moisture Resistance

Some types of insulation paper, such as aramid or polyester composites, are designed to resist moisture and humidity. This is crucial for motors used in humid or outdoor environments.

5. Cost Efficiency

Compared to other insulation methods like varnish or resin-impregnated tapes, insulation paper is lightweight, easy to apply, and cost-effective, especially in large-scale motor production.

Typical Applications in Motors

Insulation paper is widely used in:

► Slot liners

►Phase insulation

►Interturn insulation

►Layer separators

►End turn wraps

It’s commonly found in AC motors, DC motors, stepper motors, transformers, and generators.

Conclusion

Insulation paper may seem like a minor component, but it serves a major function. It enhances the motor’s lifespan, improves safety, and ensures efficient operation. As electric motors continue to evolve, especially in the era of EVs and automation, high-quality insulation materials like insulation paper will remain indispensable.