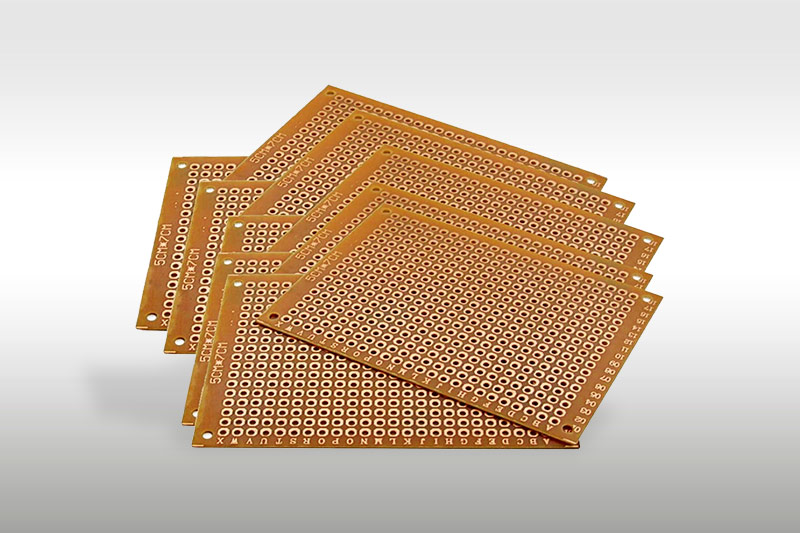

What Is FR4 and Why Does It Matter?

FR4 is a widely used composite material made from woven fiberglass cloth and epoxy resin. It is known for its excellent balance of mechanical strength, moisture resistance, and—most importantly—electrical insulation. Due to its superior properties, FR4 has become the backbone of countless applications in electronics, electrical insulation, and high-voltage engineering.

But when it comes to its electrical performance, FR4 offers a range of unique advantages that set it apart from many other materials.

1. High Dielectric Strength: Superior Voltage Withstanding Capability

One of the most critical performance metrics of any insulating material is its dielectric strength, or the maximum electric field a material can withstand without breaking down.

FR4 typically has a dielectric strength of 19.7–50 kV/mm, depending on the thickness and test conditions.

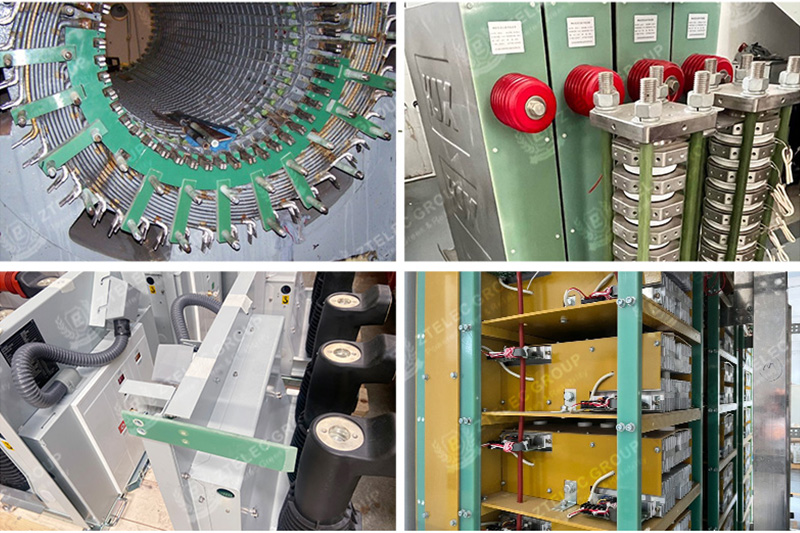

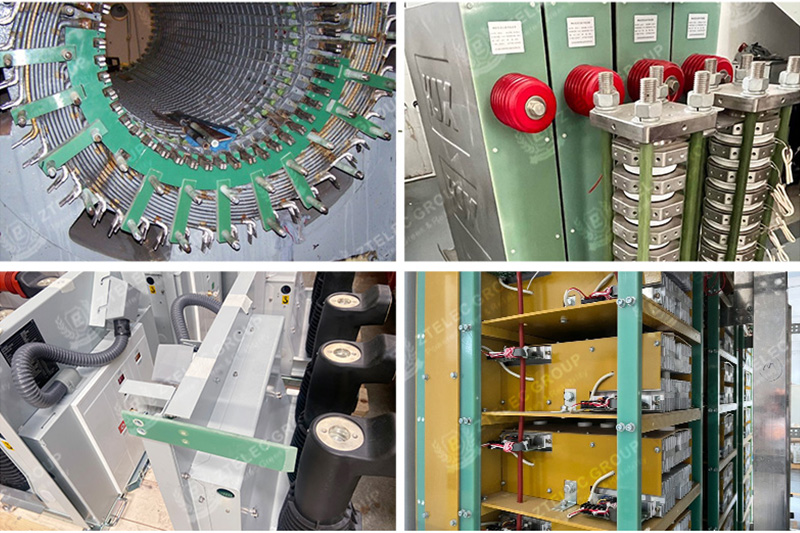

This makes it ideal for use in printed circuit boards (PCBs), switchgear components, busbar insulation, and transformer spacers.

Why it matters:

A high dielectric strength means FR4 can reliably isolate electrical components, reducing the risk of arcing, flashover, or electrical failure in high-voltage systems.

2. Excellent Insulation Resistance

FR4 is known for its very high insulation resistance, often in the range of 10^12 to 10^14 ohms. This helps maintain the integrity of circuits and prevents leakage currents, which are critical in applications where electrical reliability is non-negotiable.

Use cases include:

PCB substrates

Insulating barriers in power converters

Isolation plates in electric vehicles and battery packs

3. Low Dielectric Constant and Dissipation Factor

In high-frequency applications, the dielectric constant (Dk) and dissipation factor (Df) of the material become crucial.

FR4 typically offers a dielectric constant of 4.2–4.8 at 1 MHz, and

A low dissipation factor of around 0.02

This makes FR4 suitable for RF and microwave PCBs, where signal integrity and minimal loss are essential.

4. Moisture and Environmental Resistance

Unlike some organic insulation materials, FR4 maintains its electrical performance even in humid environments.

It has a low water absorption rate (<0.10%), ensuring that its dielectric properties are stable over time.

This is especially useful in outdoor electrical enclosures, wind turbines, and marine electronics, where insulation degradation due to moisture can be a concern.

5. Flame Retardant and Safe

The “FR” in FR4 stands for “Flame Retardant,” indicating that the material meets the UL94-V0 standard. In environments where electrical safety and fire protection are priorities, FR4 is a trusted choice.

Conclusion: FR4 – The Trusted Standard for Electrical Insulation

FR4 is not just another industrial laminate. It is a high-performance electrical insulation material designed to meet the demanding requirements of modern power, electronics, and energy systems. With its high dielectric strength, excellent resistance properties, and stability under thermal and environmental stress, FR4 continues to power innovation across industries.

Whether you're manufacturing printed circuit boards, insulating high-voltage components, or developing electric vehicle systems, FR4 remains a reliable, efficient, and cost-effective choice.

Looking for FR4 Sheets or Custom Parts?

ZTelec offers high-quality FR4 sheets, CNC-machined insulation components, and expert OEM/ODM services. Contact us today to learn more about our insulation solutions for global markets.

Email: suooprt1@ztelecgroup.com

Website: www.ztelecpro.com