G10 Multicolor Sheets: The Core Material Behind Unique Knife Handles

In the world of high-performance knife making, G10 multicolor laminate sheets are earning recognition not only for their durability but also for their aesthetic appeal. From tactical folders to custom-crafted blades, these materials have become a go-to choice for professional knifemakers and DIY enthusiasts alike.

What Is G10 Multicolor Laminate?

G10 is a type of fiberglass-reinforced epoxy resin laminate, created by layering glass cloth soaked in epoxy and compressing it under high heat and pressure. The result is a rigid, lightweight, and highly durable material that’s resistant to moisture, chemicals, and mechanical stress.

What makes multicolor G10 unique is the stacking of colored layers before compression. These layered sheets are then machined, ground, or shaped to reveal stunning patterns, lines, and swirls—making each knife handle a true one-of-a-kind design.

Why G10 Is Ideal for Knife Handles?

1. Superior Grip & Texture

G10 can be textured or machined to provide a non-slip grip, making it an excellent option for outdoor, tactical, and utility knives.

2. Custom Aesthetic Appeal

Whether you're looking for a vibrant red-black swirl, classic camo, or layered earth tones, multicolor G10 adds visual impact and brand identity to each knife design.

3. Durability in Harsh Conditions

G10 resists moisture absorption, temperature fluctuations, and UV exposure—ideal for knives used in wet, hot, or extreme environments.

4. Lightweight & Balanced

Despite its toughness, G10 is remarkably light, which helps maintain ergonomic balance in handle design without sacrificing strength.

G10 plate is used not only for tool handles, but also for:

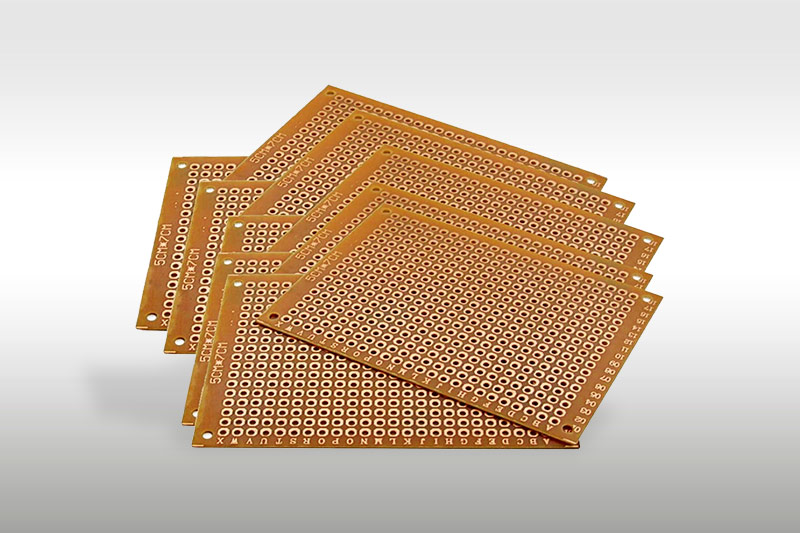

► Insulation brackets, partitions, slot wedges, etc. in motors and transformers.

► PCB substrate (printed circuit board)

► High-voltage switchgear: used as insulating spacers, baffles, connecting plates, etc.

► CNC machining tooling, wear-resistant and cutting-resistant.

► Electrical box support parts

Choosing the Right G10 Sheet

When selecting G10 for your project, consider:

Sheet Thickness: Common thicknesses range from 0.5mm to 60mm depending on grip size or layering needs.

Machinability: Use carbide tools and dust extraction, as G10 is abrasive to cutting edges.

At ZTelec, we provide custom-cut G10 multicolor sheets in a variety of color schemes and sizes. our material quality ensures consistency, strength, and visual appeal.

Final Thoughts

G10 sheets are more than just stylish—they're engineered for performance. As knife makers demand both form and function, these materials deliver the perfect balance. If you're looking to elevate your knife designs with a durable, visually striking handle, G10 sheets are the answer.

Explore our full G10 series at ztelecpro.com or contact us for samples and custom cutting services.