How Good Is the Electrical Insulation Performance of Bakelite Sheets: Key Factors You Should Know

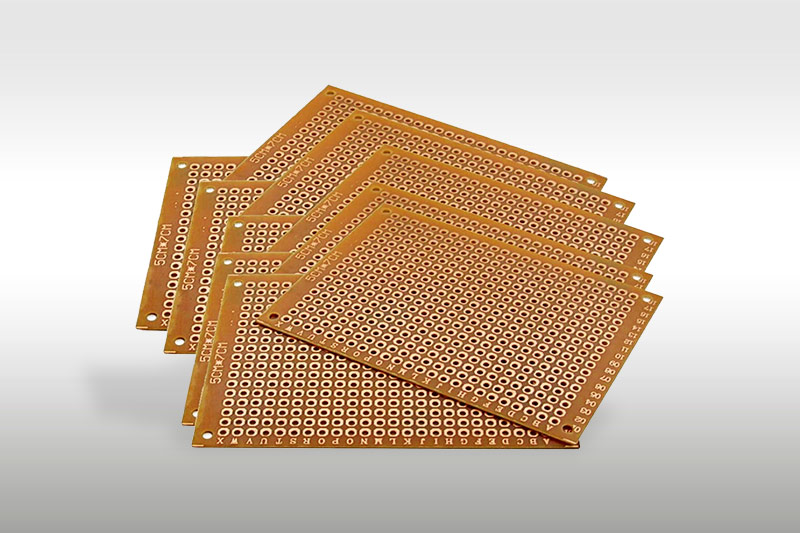

Bakelite sheets, also known as phenolic laminated sheets, have long been trusted as reliable electrical insulation materials in transformers, electrical switchgear, motor parts, and electronic devices. Their excellent insulation performance, combined with good machinability and heat resistance, makes them widely used in electrical applications around the world. But how good is the electrical insulation performance of Bakelite sheets, and what key factors should be considered when choosing them? Let’s take a closer look.

What Is a Bakelite Sheet?

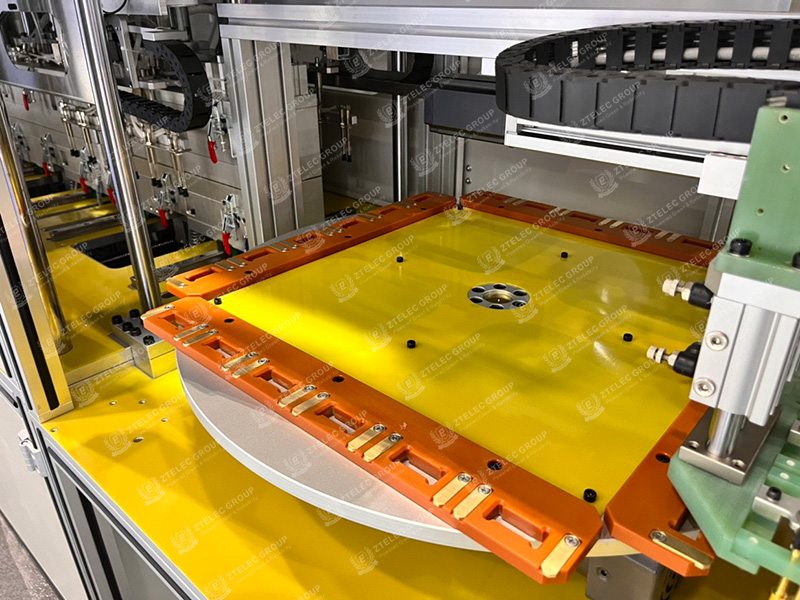

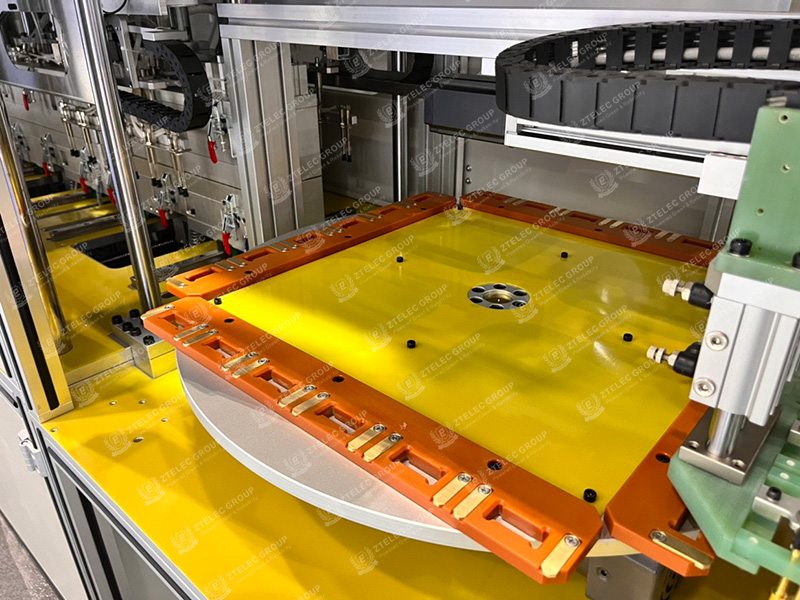

Bakelite sheet is a type of phenolic resin-based laminated board, made by impregnating layers of paper, cotton fabric, or wood veneer with phenolic resin and pressing them under heat. The result is a rigid, durable, and high-insulating board widely used in electrical, mechanical, and industrial fields.

Electrical Insulation Properties of Bakelite Sheets

1️⃣ High Dielectric Strength

Bakelite sheets offer excellent dielectric strength, typically ranging from 15 to 25 kV/mm. This high dielectric strength ensures reliable insulation, preventing electrical leakage, short circuits, or breakdowns in medium and low-voltage systems.

2️⃣ Excellent Insulation Resistance

With surface and volume resistivity often exceeding 10^8 Ω·m, Bakelite sheets maintain stable insulating properties even in humid or challenging environments, providing enhanced safety for electrical devices.

3️⃣ Strong Arc Resistance

Bakelite sheets can withstand high-voltage arcs for extended periods without breakdown, offering reliable protection in systems where high-voltage discharge is a risk, such as transformers and high-power control systems.

4️⃣ Good Heat Resistance

Bakelite sheets typically perform well under temperatures ranging from 120°C to 150°C, and special grades can endure up to 160°C, making them ideal for use in transformers, motors, and other heat-generating electrical devices.

Key Factors Affecting Insulation Performance

To maximize the electrical insulation performance of Bakelite sheets, several factors should be carefully considered:

The purity of phenolic resin and the quality of reinforcement materials like cotton fabric or paper directly affect the final insulating performance and stability of the sheet.

Thicker sheets generally offer higher dielectric strength and better insulation, but they may increase material cost and reduce machining flexibility. Proper selection based on application requirements is important.

-

Humidity and Moisture Exposure

Although Bakelite has good moisture resistance, long-term exposure to high humidity can lower its insulation resistance. It’s recommended to use it in dry, well-ventilated environments for optimal performance.

Continuous use in temperatures exceeding the material’s heat resistance grade can cause aging, reducing insulation effectiveness and increasing the risk of failure.

Conclusion

Bakelite sheets deliver outstanding dielectric strength, insulation resistance, arc resistance, and heat resistance, making them one of the most trusted insulating materials for electrical applications. When selecting Bakelite sheets, it’s crucial to consider material quality, sheet thickness, environmental humidity, and operating temperatures to ensure optimal performance and long-term reliability.

If you’re looking for high-quality Bakelite insulation boards, ZTelec offers a wide range of customized sizes and grades to meet your specific project requirements. Contact us today for a quote or to learn more!