Abstract

In the shoemaking industry, molds are the core elements that determine the quality of shoes. The quality and precision of molds directly affect the final performance of finished shoes. In this context, epoxy sheet has successfully established a foothold in the key field of shoe mold manufacturing with its outstanding performance and has been widely used.

Industry Overview

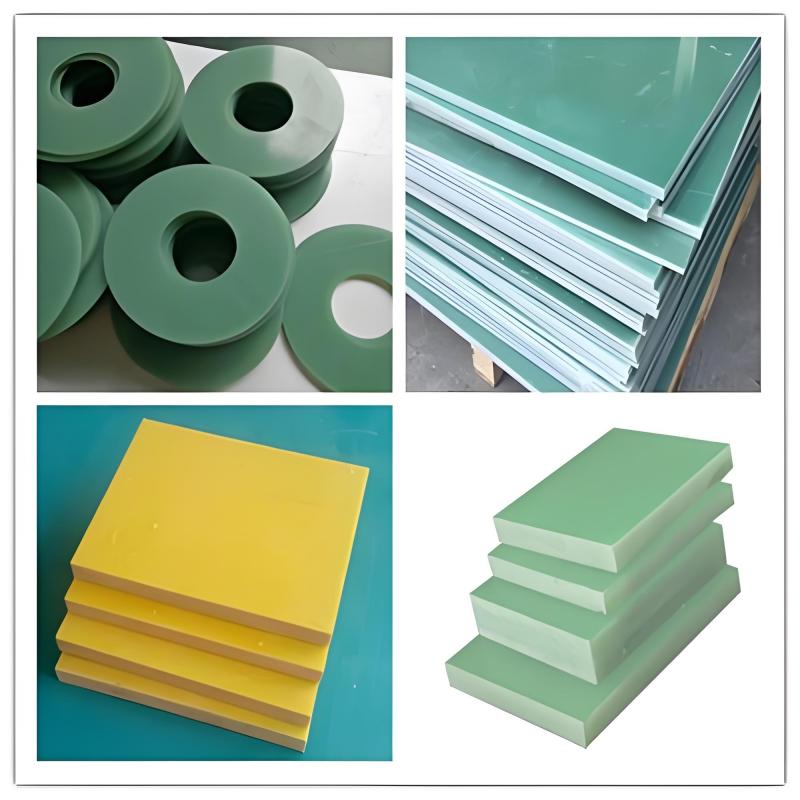

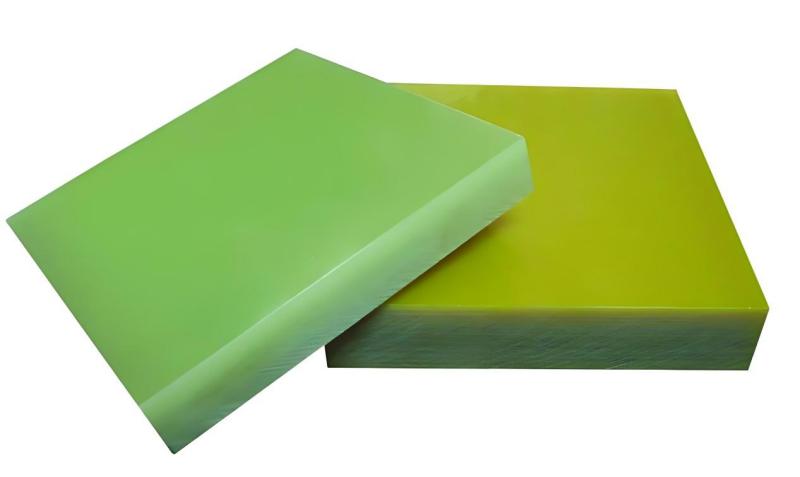

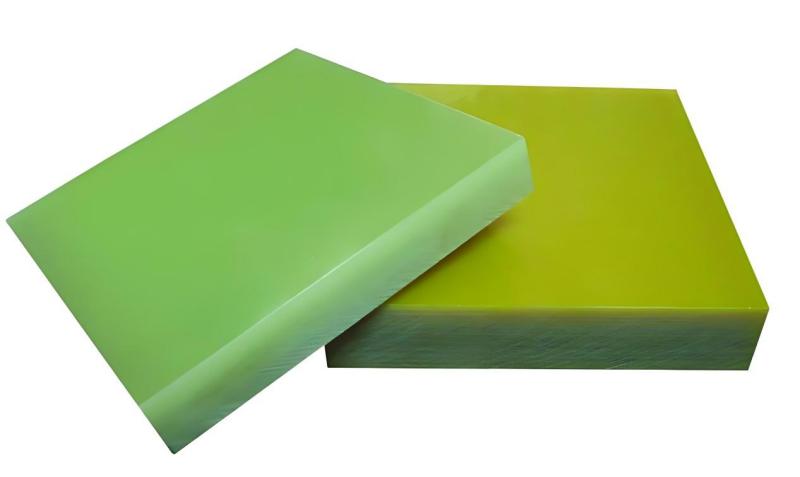

As a key "role" in the shoemaking production process, the performance of shoemaking molds is closely related to the appearance, comfort and durability of shoes. At present, the shoemaking industry has become more and more strict in controlling product quality and pursuing production efficiency. Traditional mold materials are gradually showing their inability to cope with such a new situation. On the other hand, epoxy sheet, as a high-performance composite material, has a series of outstanding characteristics that meet the needs of shoe mold manufacturing. The high strength of epoxy sheet can ensure the structural stability of the mold under complex processes; its excellent dimensional stability ensures that the mold always maintains precise specifications during multiple uses; and its excellent heat resistance and chemical corrosion resistance make the mold withstand the harsh environment in the production process. For this reason, the application of epoxy sheet in shoe mold manufacturing is becoming more and more common.

In view of the profound impact of shoe molds on the quality and production efficiency of the finished shoes, the modern shoemaking industry has set extremely strict standards for mold materials:

·Dimensional accuracy requirements: Shoe molds must have extremely high dimensional stability, and the dimensional error must usually be accurately controlled within ±0.1mm to ensure the accuracy of the shoe version.

·Surface quality requirements: The smoothness of the mold surface is very important and must reach a mirror or near-mirror level to ensure that the shoe material has ideal quality during molding.

·Heat resistance: The mold must have strong high temperature resistance and be able to calmly cope with high temperature environments of 120-180℃ in injection molding, vulcanization and other process links.

·Mechanical durability: High-quality molds should be able to withstand thousands or even tens of thousands of frequent repeated uses without deformation and other conditions, ensuring long-term stable production.

·Economic considerations: On the premise of fully meeting various performance requirements, the manufacturing cost of the mold should be reduced as much as possible to improve the economic benefits of the enterprise.

·Processing convenience: The selected materials should be easy to process into complex and varied three-dimensional curved shapes to meet diverse design requirements.

Traditional shoe mold materials, such as aluminum alloy and steel mold, have certain advantages in performance, but they also have prominent problems such as high cost and long processing cycle. In comparison, epoxy sheet has incomparable unique advantages in many aspects due to its balanced performance and relatively affordable cost.

Solutions for epoxy sheets used in shoe factories

Sole mold

In the field of sole mold manufacturing, epoxy sheet is the most widely used. As a key component of shoes, the shape accuracy and quality of the sole are directly related to the comfort of the shoe when worn and the durability of the product. With its high strength and excellent dimensional stability, epoxy sheet can accurately reproduce the design shape of the sole, laying a solid foundation for the molding quality of the sole. During injection molding, the good heat resistance of epoxy sheet enables it to withstand the impact of high-temperature plastic melt, effectively preventing the sole mold from being damaged by high temperature. For example, in the production process of sports shoe soles, with the help of FR4 epoxy sheet molds, soles with complex patterns and precise dimensions can be created, significantly improving the grip and shock absorption performance of the shoes.

Upper mold

The shape design and fit of the upper also play a decisive role in the appearance and comfort of the shoe. Epoxy sheet also performs well in the production of upper molds, especially for those upper designs with complex curves and fine structures. Its good processing performance allows mold manufacturers to accurately carve out various upper molds according to design requirements. In addition, the surface flatness of epoxy sheet is extremely high, which enables the upper to obtain a smooth and uniform surface effect during the molding process, greatly improving the appearance quality of the shoe.

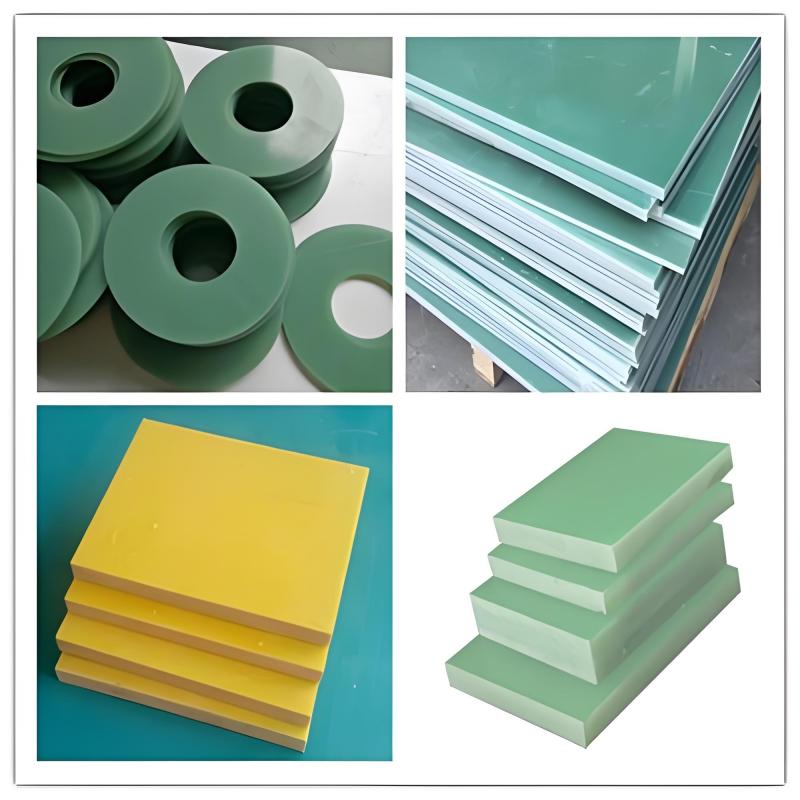

Related to our products are:

|

Sequence number |

Product name |

Model |

Application |

|

1 |

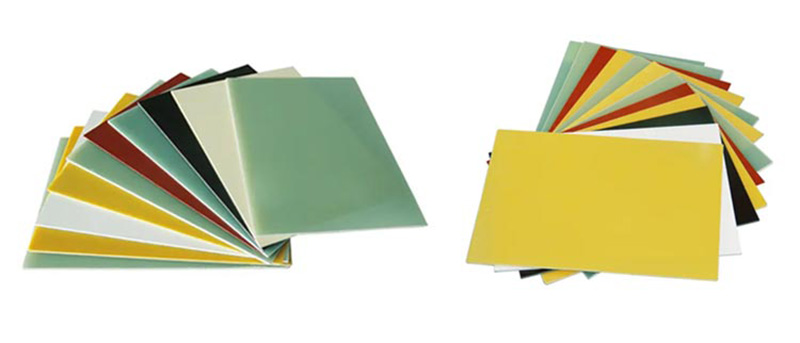

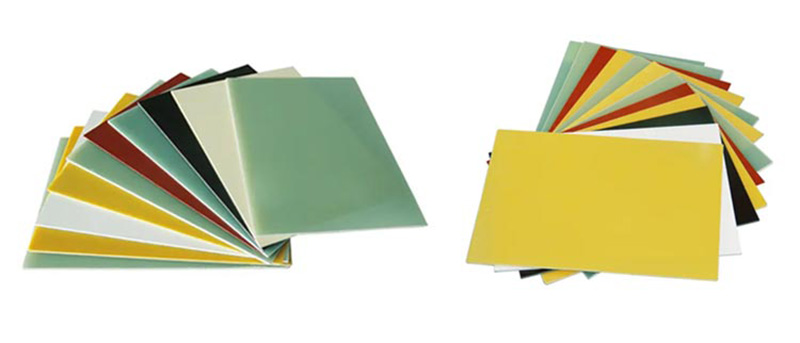

3240 epoxy glassfiber sheet |

EPGC210/202(FR4)/203(G10)/204(FR5)/306(G11)/308 |

Insulating structural parts for mechanical,electronic and electrical equipment, |

|

2 |

G10 |

No |

Used in motor,electrical equipment,insulating structural parts |

|

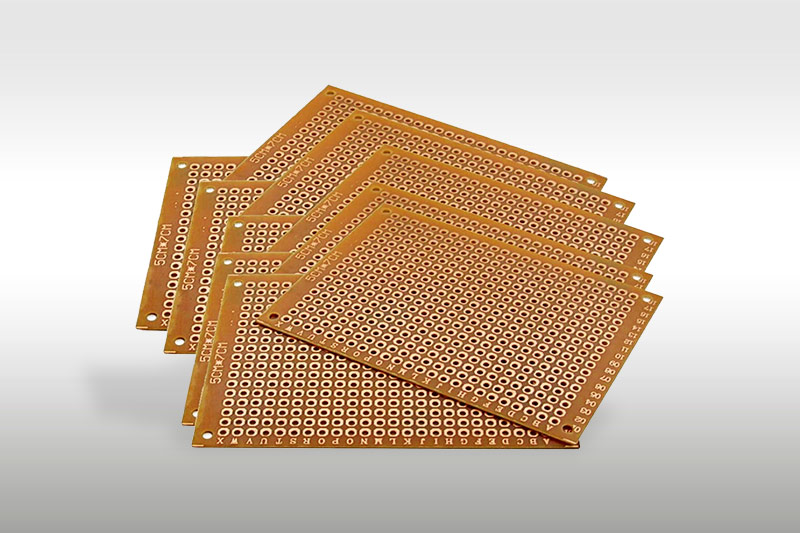

3 |

FR4 |

No |

Used in electronic,electrical,communication and other fields; |

Summary

Epoxy sheet has become an important material choice in the field of modern shoe mold manufacturing due to its excellent comprehensive performance. In key aspects such as precision maintenance, processing convenience and cost-effectiveness, epoxy sheet has shown significant advantages, which is highly consistent with the development trend of small batches, multiple varieties and fast pace in the shoemaking industry. With the continuous innovation and progress of material technology and processing technology, the application scope of epoxy sheet in the field of shoe molds will be further expanded, and the application depth will continue to deepen.