Bakelite Sheet, also known as Phenolic Sheet, is a type of laminated thermosetting plastic made by impregnating paper or cotton cloth with phenolic resin and applying heat and pressure. It is one of the earliest synthetic plastics, famous for its excellent insulating, heat-resistant, and mechanical properties.

Property && Performance

Electrical Insulation:Excellent dielectric strength

Heat Resistance: Up to 130°continuous usage

Mechanical Strength: High compressive and impact resistance

Dimensional Stability: Maintains shape under stress

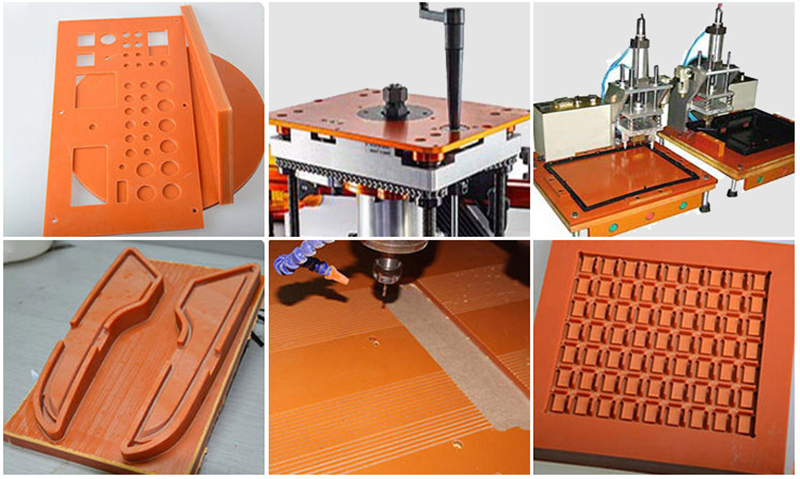

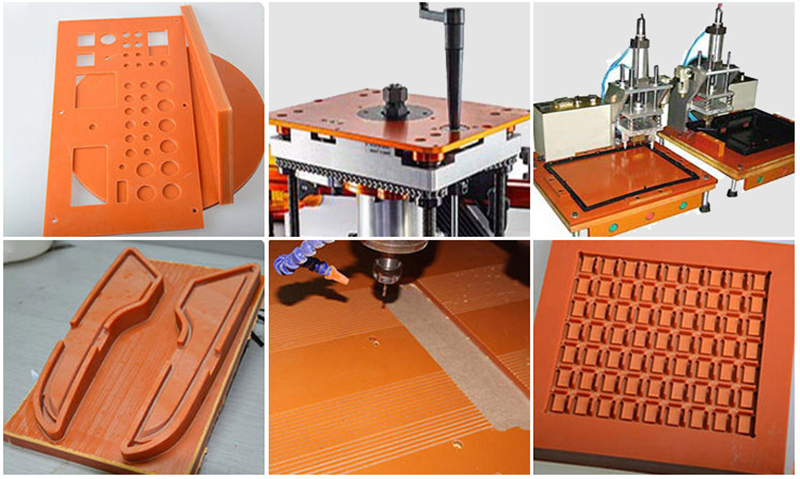

Machinability: Easy to cut, drill, and fabricate

Bakelite Sheets are widely used in industries such as:

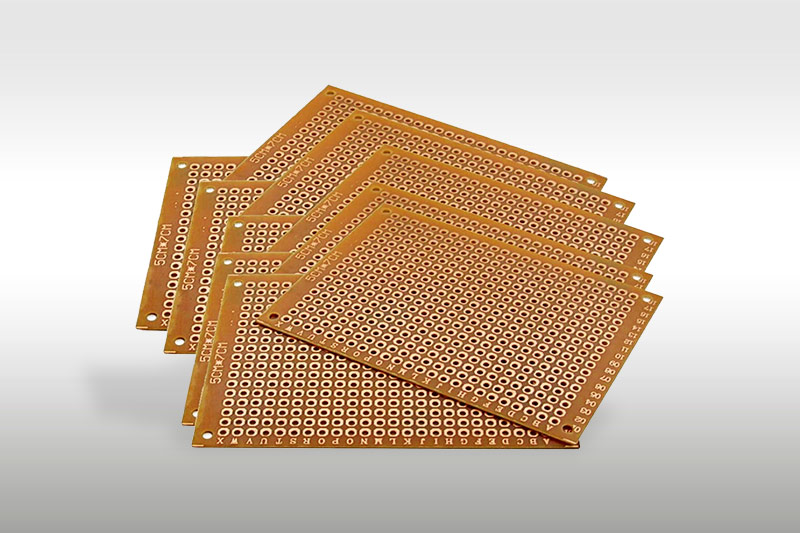

Electrical & Electronics:Used as insulating boards, switchgear components, control panels, and motor parts.

Mechanical Engineering:Machine tool fixtures, gaskets, gears, and structural supports.

Household Appliances:Heat-insulating pads, handles for cookware, and electrical housings.

Automotive Industry: Brake pads, clutch plates, and insulation panels.

At ZTelec Group, we produce high-quality Bakelite Sheets with:

-

Stable electrical performance

-

Consistent thickness and smooth surface

-

Custom sizes and colors available

-

Reliable supply and fast delivery

Our Bakelite Sheets are trusted by customers worldwide for their durability, insulation performance, and competitive pricing.

If you're looking for reliable Bakelite Sheets for your projects — ZTelec is here to help.